Search the whole station Crushing Equipment

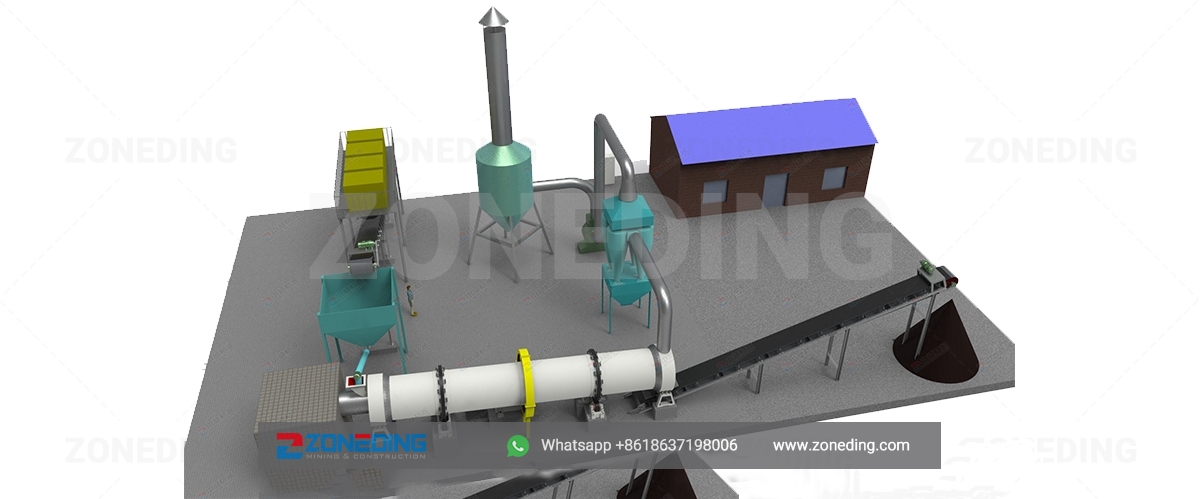

The fly ash dryer produced by Zoneding Machinery is a rotary drying equipment used for drying materials like fly ash, phosphor gypsum, and industrial waste. It is known for its reliable operation, efficient drying, and high capacity.

Fly ash dryer produced by Zoneding Machinery is widely used for drying fly ash, phosphor gypsum, industrial dust and waste slag. It is also known as of powdered coal ash dryer or pond ash dryer. This dryer is a type of rotary drying equipment and also plays a key part. It has numerous features such as reliable operation, excellent drying effect, high thermal efficiency and large capacity.

Besides, fly ash dryer has resolved the pollution and tough disposal problems of fly ash, which not only narrows the pollution, but also turns waste into resources and improves the economic benefit.

Fly ash is a very fine powder made up of tiny, spherical glassy particles that are carried away from the combustion chamber of a coal-fired boiler. When coal is burned, the non-combustible mineral impurities melt and, as they exit, rapidly cool and solidify into these microscopic spheres. It is a pozzolan, meaning it has cement-like properties when mixed with water and calcium hydroxide. This makes it a highly valuable resource, especially in the construction industry.

Fly ash is not a simple powder. Its properties present unique challenges. It is extremely fine (often smaller than cement particles) and has a low bulk density. When wet, it becomes sticky, cohesive, and prone to clumping. The number one killer of any drying operation is the “mud ring”—a hard, concrete-like dam that can build up inside the dryer, choking the entire process. A properly designed fly ash drying system must be engineered specifically to combat this stickiness.

Wet fly ash has limited value. It is heavy, expensive to transport, and difficult to use in high-value applications. Drying it down to a moisture content of less than 1% changes everything.

The bottom line: an efficient dryer can have a return on investment of less than a year, simply by increasing the value of your existing material.

The most common and effective type of industrial dryer machine for this application is the rotary dryer. A fly ash dryer, specifically, is a rotary dryer that has been heavily modified to handle the unique challenges of fly ash. It is a large, rotating cylindrical drum, slightly inclined, that uses a flow of hot gas to dry the material as it tumbles through. It’s designed not just to evaporate water but to do so without letting the sticky ash build up inside and without overheating and destroying the material’s valuable properties.

For a tough, abrasive material like fly ash, the rotary dryer is the superior choice for several reasons. First, it is extremely robust. These machines are industrial workhorses, built from thick steel to withstand abrasion and run continuously for years with proper maintenance. Second, they can handle a wide range of input conditions.

A ZONEDING rotary dryer can manage fluctuations in moisture content and lump size far better than more sensitive technologies like flash dryers. Third, they offer high throughput, with models available to handle the massive capacities required by power plants and cement factories. Finally, they are flexible with their energy source. Our rotary dryers can be paired with burners using natural gas, oil, or coal, and are ideally suited for integration with “free” waste heat from another plant process, dramatically lowering your operational costs.

Our rotary dryers are designed to be versatile and can handle virtually any type of fly ash, though the system configuration will change based on the source. We handle two main categories:

Adopting new type international technology, Zoneding fly ash drying equipment is widely used in the advanced utilize of cement clinker, cement mixing materials, large hydro project, pump concrete, large-volume concrete products, high-grade filler, baked brick, etc.

In addition, fly ash dryer made by Zoneding Machinery is commonly used in ore processing, building materials, metallurgy, railway, highway, and other fields for drying materials with certain humidity like ore powder, zin powder, kaolin, limestone, fly ash, phosphor gypsum, industrial dust and waste slag, etc.

Applications of Fly Ash Dryer

Benifits of Fly Ash Dryer

Convection and heat conduction are mainly used in the drying process. When the hot wind in the oven gets the set temperature, the dryer works with the order from the PC system. Wet fly ash is then sent into the inner layer of the fly ash drying equipment by the feeder evenly and goes with the scorching wind. The wet material is sent spirally by the fixed shoveling plate.

Next, the material moves to another end of the oven and into the middle layer. This time, wet ash moves forward against the wind stepping back in two steps. Here in the intermediate layer, heat from the inner layer and the middle layer is fully utilized, thus the drying efficiency is improved to the best situation.

Lastly, dried fly ash gets to the other end of the intermediate layer and into the outer layer moving in rectangular and multi-loop mode. Fly ash that is dried to satisfactory is blown out of the dryer with the effect of the hot wind. The other will move more slowly on its weight and be dried one more time in the outer layer to required humidity.

Working Principle of Fly Ash Dryer

A professional fly ash dryer is far more than just an empty tube.

The rotary drum dryer working principle is a continuous process of lifting and showering.

The process of drying fly ash in our plants is a carefully controlled, multi-stage operation designed for efficiency and product quality.

We focus on the details that impact your long-term operational costs and reliability.

The fly ash dryer machine price can range from $80,000 for a small, simple system to over $1,000,000 for a large-scale, high-capacity, fully integrated plant. The price is a direct function of its water evaporation capacity—how many tons of water it can remove per hour. A dryer for high-moisture pond ash will be significantly larger and more expensive than one for lower-moisture silo ash. An investment in a properly sized and engineered dryer from a reputable fly ash dryer manufacturer will pay dividends in fuel savings and uptime.

Choosing the right fly ash drying equipment is a technical decision.

In coal-fired boiler of the power plant system, the emission of coal ash can be divided into 2 types, dry emission, and wet emission. As a kind of favorite resources, dry coal ash is of great economic value; wet emission will cause certain pollution to the environment. Processing of moist coal ash has grown up to be an urgent problem at present.

Fly Ash Dryer recycles the burnt coal powder and dries it into fly ash that can be used in concrete and other fields. It is an energy-saving process. This dryer and the collector equipped collecting the ash avoiding it getting into the air or the rivers, which is environmental protection. Compared to the traditional dryer, this new type Fly Ash Dryer gives a maximum utilization of the heat. Efficiency is upgraded and fuel is saved.

Value of Fly Ash Dryer

Fly ash is mixed material produced by coal powder when it is burned at high temperature (some like volcanic ash). Coal powder is milled into particle less than 100 micrometers and is burnt into high temperature smoke mixed with lots of incombustible matter. With the dust collecting system, we go to get the fly ash. Environmental pollution and energy waste are aroused if fly ash is not utilized rationally. For the recycling, the Fly Ash Dryer is born.

Dried fly ash can be used to make cement clinker, baked brick, aerated concrete and hollow brick for the construction of roads and dams. In addition, the floating beads, microbeads, powdered iron, carbon and aluminum can be selected from fly ash to make other materials.

Applications of Fly Ash

Proper maintenance ensures a long service life and consistent performance.

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

What Makes a Dryer Energy-Efficient and Cost-Effective?

Efficiency comes from maximizing heat transfer. A dryer with a zoned lifter design that creates a dense, uniform curtain of material is highly efficient. The most cost-effective solution is using a dryer designed to run on low-temperature waste heat from another part of your plant, which makes your fuel cost essentially zero.

How Can You Control the Final Moisture Content Precisely?

You control it by balancing three variables: the feed rate of the wet material, the temperature of the hot gas entering the dryer, and the rotation speed of the drum. A modern system uses sensors and a PLC control panel to automatically adjust these parameters to maintain a consistent outlet moisture.

How Does the System Manage Dust and Meet Environmental Standards?

A high-efficiency baghouse is essential. It captures the ultra-fine dust particles from the exhaust gas, ensuring clean emissions. Importantly, the dust it captures is valuable product, which is then combined with the main product stream, turning an environmental requirement into a profit center.

How Do You Determine the Right Dryer Size and Capacity?

It’s a simple calculation: if you want to produce 50 tons per hour of dry fly ash (at <1% moisture) from wet ash with 20% moisture, you need to evaporate approximately 12.5 tons of water per hour. The dryer must be sized based on this evaporation capacity, not just the final product tonnage.

What Factors Ultimately Determine the Dryer’s Price?

The main factors are: 1) Evaporation capacity (the biggest driver). 2) The materials of construction (stainless steel vs. carbon steel, type of internal liners). 3) The fuel source (a coal burner is more complex than a gas burner). 4) The scope of supply (dryer only versus a full system with baghouse, conveyors, and controls).

Buy industrial gypsum dryer for sale. Efficiently remove moisture from gypsum rock & powder. Improve product quality & processing speed.

Rotary cooler for sale. Efficiently cool hot materials discharged from kilns & dryers. Improve process speed & material quality.

Buy industrial rotary kiln for sale. Achieve efficient high-temperature thermal processing, calcining, roasting & drying of minerals, ore, cement & more.

Find high-efficiency sludge dryers for sale. Reduce sludge volume, cut disposal costs, and improve handling. Ideal for municipal & industrial applications.

Discover high-performance aggregate and sand dryers for sale. We offer triple-pass and rotary drum models for efficient moisture removal. Get a quote today!

Looking for a high-efficiency triple-drum rotary dryer? Saves energy, space, and cost; suitable for drying sand, coal, and biomass. Rugged and reliable.

Purchase an industrial bentonite dryer suitable for various applications such as drilling mud, cat litter, and foundry work. Achieve optimal moisture content and uniform drying.

Specialized Coal Dryer machines for power generation, coking, and briquetting. Improve fuel efficiency, reduce transport costs & enhance combustion.

Professional slurry dryer manufacturer with CE/ISO certification. Customizable 5-50t/h capacity, 35% energy saving. Get instant technical specs download.

Professional slag dryer manufacturer with CE/ISO certification. Energy-saving 30%, global delivery to 50+ countries. Get custom solutions for mining waste processing.

loading…

已经是到最后一篇内容了!