The Ultimate Guide to Gold Gravity Beneficiation

3542This expert guide details the process of gold gravity beneficiation, helping you optimize equipment settings and techniques for maximum recovery.

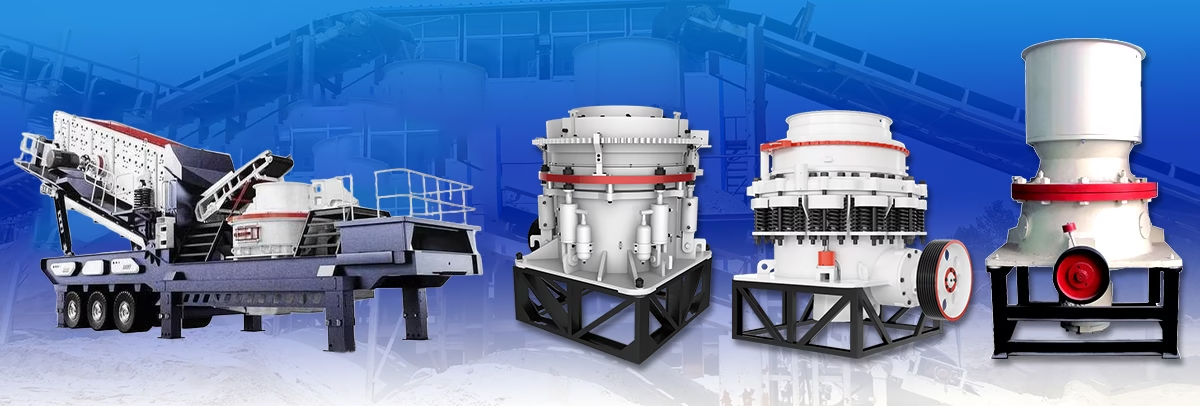

View detailsSearch the whole station Crushing Equipment

Proper cone crusher selection is critical to the profitability of any crushing operation. The market offers a wide range of cone crusher types, including spring, single-cylinder hydraulic, multi-cylinder hydraulic, and mobile units. This guide provides a direct, technical comparison to help you make an informed investment decision based on your specific project requirements. It is a framework for choosing the right tool for the job.

This guide will focus on the operational and financial factors that drive correct crushing equipment selection. My experience in specifying, operating, and maintaining these machines has shown that understanding the fundamental design differences is the key to a successful production line.

Your first choice is not about the crusher itself, but about your business model. Are you moving from site to site, or are you staying put for the next decade? This one decision changes everything.

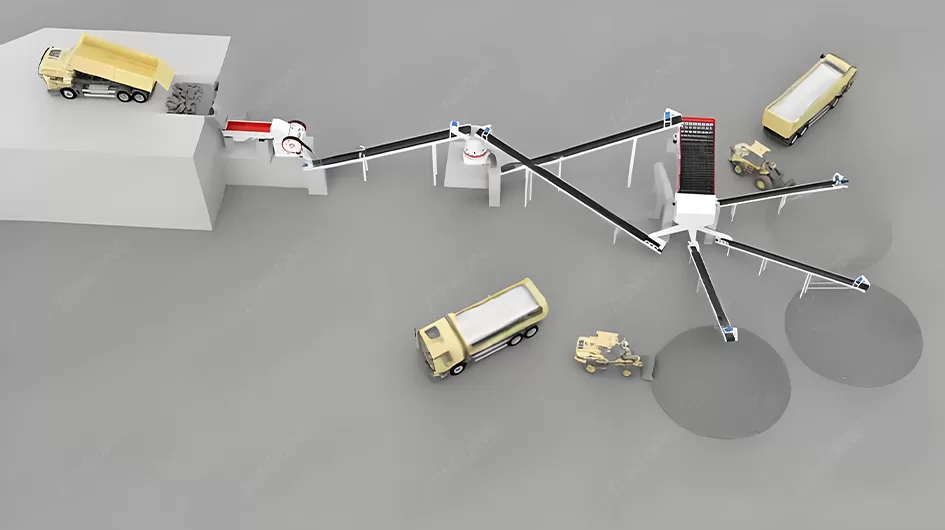

A stationary cone crusher is part of a permanent or semi-permanent plant built on concrete foundations. It is designed for long-term, high-volume production at a single site. In contrast, a Mobile Cone Crusher integrates the crusher, screen, and conveyors onto a single wheeled or tracked chassis. It is designed for flexibility and rapid deployment.

| Factor | Mobile Production Line | Stationary Production Line | Your Project Application |

|---|---|---|---|

| Setup Time | Hours or days | Weeks or months | For short-term contracts or quick start-ups. |

| Flexibility | High (can move between sites) | Low (fixed installation) | For contractors with multiple job sites. |

| Initial Capital | Generally lower (no civils) | Higher (requires foundations) | When upfront capital is a primary constraint. |

| Throughput | Moderate to high | Very high | For large-scale quarries and mines. |

| Ideal Project | < 2-3 years, multiple locations | > 3 years, single location | Matches the operational lifespan to the investment. |

A mobile cone crusher offers the highest return on investment (ROI) in specific scenarios defined by flexibility and project duration. Investing in a mobile unit is the correct financial decision when your operation is not fixed to one location for many years.

These situations include:

The ability to avoid significant civil engineering costs and to transport the entire plant to a new source of revenue is the core financial advantage. A Tracked Cone Crusher, for instance, can be unloaded from a transport truck and begin crushing in a matter of hours, maximizing uptime and revenue generation.

A mobile unit is a versatile tool. A stationary plant is a factory. If your goal is to produce hundreds of thousands of tons of aggregate per year from one location, there is no substitute for a fixed plant.

A Stationary cone crusher offers unmatched throughput, the lowest possible operating cost per ton, and higher stability, making it ideal for large-scale, long-term quarries and mining operations.

When you are in a game of pennies per ton, efficiency and scale are everything. A stationary plant is designed from the ground up to maximize both. It’s a bigger investment, but it delivers superior performance for massive operations.

The advantages of a stationary production line configuration are all about long-term efficiency.

| Feature | Stationary Cone Crusher | Mobile Cone Crusher |

|---|---|---|

| Max Throughput | Very High (up to 2000+ TPH) | Moderate (up to 500 TPH) |

| Cost Per Ton | Lowest | Higher |

| Lifespan | Very Long (20+ years) | Long (10-15 years) |

| Ideal Project | Single site, > 5 years | Multiple sites, < 5 years |

The Spring Cone Crusher, also known as the Symons cone crusher, is the original design. It uses a set of heavy-duty springs for overload protection. If uncrushable tramp metal enters, the springs compress to allow the material to pass.

In 2025, its cost advantage is limited. While the upfront equipment price is lower, its operational inefficiencies often lead to a higher total cost of ownership. Adjusting the product size (Closed-Side Setting or CSS) is a slow, manual process that requires shutting down the machine. This results in significant production downtime. For most modern operations, the benefits of hydraulic crushers outweigh the initial savings of a spring cone.

You should only consider a new spring cone crusher in two situations:

The single-cylinder design is the modern all-rounder. It replaced the springs and manual adjustment with one large hydraulic cylinder, and this changed everything. It is the perfect balance of performance and reliability.

A Single-cylinder hydraulic cone crusher lowers costs by allowing setting adjustments while running, which maximizes uptime and product quality. Its automated tramp release system also prevents costly damage and downtime.

This is the default choice for most modern quarries for a reason. The hydraulic cylinder at the base does two jobs perfectly: it sets the product size with precision, and it provides overload protection.

The real magic is the ability to optimize your plant in real time.

| Feature | Single-Cylinder Hydraulic Cone Crusher |

|---|---|

| Adjustment Method | Hydraulic, on-the-fly |

| Protection System | Automated tramp release & recovery |

| Key Benefit | Maximizes uptime and product consistency |

| Cost Profile | Moderate initial cost, low long-term operating cost |

The multi-cylinder crusher is not just an upgrade. It is a different class of machine. It is a high-performance beast designed for the toughest jobs on the planet.

A Multi-cylinder hydraulic cone crusher uses multiple hydraulic cylinders to generate immense crushing force. This makes it ideal for hard rock crushing, like iron ore or granite, at very high production rates, while also producing an excellent final product shape.

Think of this machine as a Formula 1 car. People buy them thinking “more cylinders must be better,” and that is a huge mistake. It’s a thoroughbred designed for a specific race.

You choose this machine when the rock demands it.

| Application | Best Crusher Type | Reason |

|---|---|---|

| Limestone Aggregate | Single-Cylinder Hydraulic Cone Crusher | Balanced performance, lower energy cost. |

| River Gravel | Single-Cylinder Hydraulic Cone Crusher | Good all-around performance. |

| Granite / Basalt | Multi-Cylinder Hydraulic Cone Crusher | High force needed for hard rock. |

| Iron Ore | Multi-Cylinder Hydraulic Cone Crusher | Maximum throughput and force required. |

Making the right cone crusher selection requires analyzing your specific project data. Before contacting a supplier, you should have clear answers to three critical questions. This information is essential for us to provide you with an accurate selection proposal.

With this data, our engineers at ZONEDING can develop a tailored production line configuration that matches the right machine to your exact needs. We provide factory-direct sales, ensuring a competitive detailed quotation for a solution designed to maximize your profitability.

Since 2004, ZONEDING has been a manufacturer of a comprehensive range of Crushing Equipment for the mining and aggregate industries. We specialize in providing complete, customized Stone Crushing Plants, from individual machines to full-turnkey production lines. Our 8,000-square-meter facility and team of 15 professional engineers ensure our products deliver reliable performance and value. We have exported our equipment to over 120 countries.

Contact us today to provide your project details and receive a professional, no-obligation selection proposal and quote from our engineering team.

This expert guide details the process of gold gravity beneficiation, helping you optimize equipment settings and techniques for maximum recovery.

View detailsLearn how magnetic separation uses magnetism and froth flotation uses surface chemistry, plus see their key applications.

View detailsHow does the sand making process affect quality? Compare dry vs. wet methods on efficiency, fineness modulus, and plant setup for optimal results.

View detailsChoosing the right alluvial gold equipment is crucial. Compare trommel screens, jigs, and shaking tables to build an efficient processing line for max recovery.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy