Steel Slag Recycling System | Metal Recovery & Purification Line

Maximize iron recovery with our advanced steel slag recycling system. High-efficiency crushing, screening, and magnetic separation to turn slag into profit. Get a quote!

Steel Slag Overview: Properties, Classification

Steel slag is the waste residue produced during steelmaking, consisting mainly of calcium, silicon, iron, and magnesium oxides. It is distinct from blast furnace slag and is characterized by high density, extreme hardness, and poor grindability. Understanding the material properties is crucial before equipment selection. Steel slag is significantly harder to crush than limestone and possesses a high bond work index. It often contains large lumps of solid steel, known as “buttons,” capable of destroying standard crushers.

Slag is classified based on the furnace type. Basic Oxygen Furnace (BOF) slag, originating from converter steelmaking, has high calcium content and typically contains more large steel inclusions, requiring robust crushing stages. Electric Arc Furnace (EAF) slag, resulting from scrap steel recycling, is harder and contains more alloy elements. Ladle Refining Slag is generally powdery and easier to grind. The design of the processing line must be tailored to the specific type of slag being handled to ensure efficiency and equipment longevity.

The process flow and required equi

This Article Will Tell:

- The process flow and required equi

- Why recycle steel slag?

- The process flow and required equipment of the steel slag processing plant

- Tailings Application: Stabilization and High-Value Use

- Environmental Control: Managing Abrasive Dust

- 2026 Latest Steel Slag Processing Trends

Why recycle steel slag?

Steel Slag Recycling Process involves recovering metallic iron and producing construction aggregates, creating a dual revenue stream that makes the operation highly profitable. The recovered metallic iron is returned directly to the steel furnace as a high-quality feedstock. Meanwhile, the remaining slag, after undergoing proper treatment, effectively replaces natural stone in road bases and cement production.

Steel slag typically contains 10% to 30% metallic iron and magnetic iron oxides. With global scrap steel prices remaining high, a properly designed processing line extracts this iron to provide immediate cash flow, often covering the entire operating cost of the plant. The secondary value lies in the non-magnetic tailings. As environmental regulations increasingly restrict the quarrying of natural limestone and granite, the high density and wear resistance of steel slag make it an excellent alternative aggregate for asphalt roads and engineering backfill. Advanced processing can further grind these tailings into micro-powder for cement admixtures, achieving a zero-waste facility that solves disposal issues while generating marketable construction products.

Economic Value of Slag Components

| Component | Content % | Application | Economic Value |

|---|---|---|---|

| Scrap Steel | 5% – 10% | Steelmaking Feedstock | High |

| Magnetic Particle | 10% – 20% | Sintering Material | Medium |

| Clean Slag | 60% – 80% | Road Base / Cement | Medium/Low |

| Iron Concentrate | Varies | Iron Production | High |

The process flow and required equipment of the steel slag processing plant

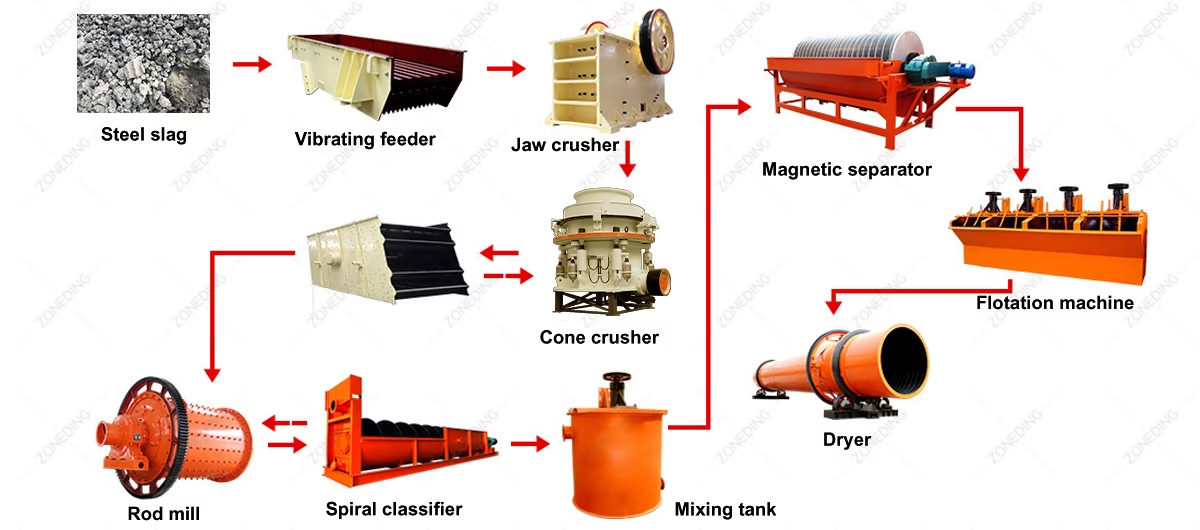

The standard process flow for a steel slag plant involves four distinct stages: Crushing, Grinding, Magnetic Separation, and Classification. Specialized equipment is required to handle the iron content effectively. The process typically begins with pre-screening to remove large steel blocks, followed by primary crushing. Magnetic pulleys are often employed after crushing to remove liberated steel early, reducing the load on subsequent stages.

Material then enters the fine crushing or grinding stage, aimed at liberating iron from the slag matrix. While wet processing is recommended for higher purity, dry processing remains common for aggregate production. The final stage involves magnetic separation using varying field strengths to separate pure iron, iron-rich slag, and clean tailings. The clean tailings are then processed by a Vibrating Screen for final sizing into 10-20mm or 20-40mm aggregates.

Rough Crushing: Why is the hydraulic jaw crusher the first choice?

The primary crushing stage handles raw slag that often contains large steel ingots, making the Jaw Crusher the only viable option due to its large feed opening and robust design. However, a standard toggle-plate jaw crusher poses a significant risk; if a solid steel block enters the chamber, the machine may suffer a broken toggle plate or a cracked frame, leading to costly downtime. Therefore, the Hydraulic Jaw Crusher is the mandatory equipment choice for this application.

The hydraulic system serves as an intelligent safety valve. When the pressure inside the crushing chamber spikes due to the presence of an uncrushable steel object, the hydraulic cylinder protecting the moving jaw automatically retracts. This action momentarily expands the discharge opening, allowing the steel object to fall through without damaging the machine, a feature known as “Over-Iron Release.” Once the object clears, the system automatically re-pressurizes and resets the jaw to the original setting. This capability ensures continuous operation and protects critical components like bearings and shafts from impact shock, which is unavoidable in steel slag processing.

Fine Crushing & Grinding: Why Cone Crushers and Rod Mills are Superior?

Following primary crushing, the material must be reduced further to liberate the iron. Cone Crushers, specifically single-cylinder hydraulic models, are recommended for the secondary stage. Similar to the jaw crusher, the hydraulic cone crusher offers excellent tramp iron release capabilities. Impact crushers are generally avoided in this stage because the abrasive nature of steel slag causes excessive wear on blow bars, making the operating costs prohibitive. The cone crusher uses a compression principle that is more energy-efficient and results in lower wear part consumption for hard materials like slag.

For the fine grinding stage, the Rod Mill provides a unique technical advantage over the traditional ball mill. The rod mill utilizes long steel rods that tumble inside the drum, creating a “line contact” grinding mechanism. This is crucial for Metallic Iron Recovery. The line contact effectively cracks the brittle mineral slag but gently flattens the malleable metallic iron particles rather than pulverizing them. This selective grinding prevents the iron from becoming too fine (sliming), which would make it difficult to recover. The flattened iron flakes are easily separated by subsequent screening or magnetic processes, ensuring a higher recovery rate and a cleaner final product.

Magnetic Separation: How to Configure for Maximum Recovery?

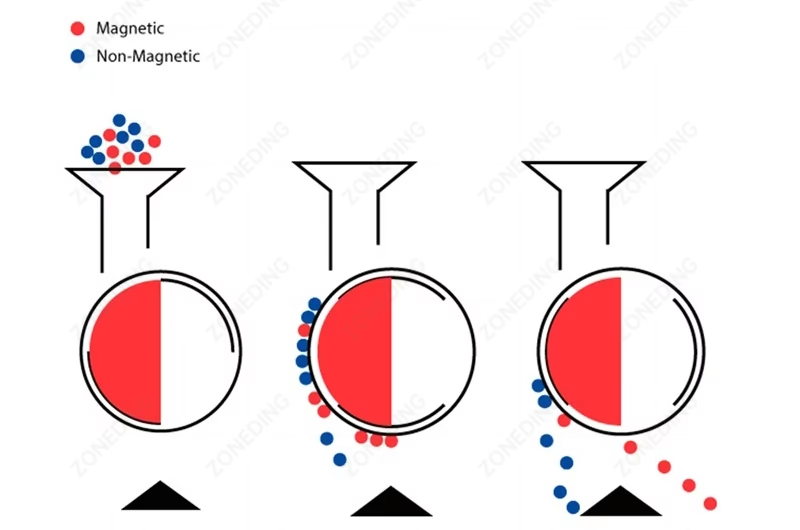

Efficient iron recovery requires a multi-stage approach using specific sequences of magnetic separation. A single pass is insufficient for maximizing value. The recommended configuration begins with a suspended magnetic separator over the conveyor after the jaw crusher to remove large scrap steel chunks immediately. This is followed by a magnetic pulley at the end of the conveyor to remove coarse magnetic particles before grinding.

In the fine processing stage, usually after the Rod Mill, a Magnetic Separator with a weak magnetic field (1200-1500 Gauss) is employed to capture highly magnetic, pure metallic iron powder. The tailings from this stage are then processed by a medium field separator (3000-5000 Gauss) to capture “middlings”—particles where iron and slag are intergrown. These middlings are returned to the mill for regrinding, ensuring that valuable iron is not lost to the tailings pile.

Tailings Application: Stabilization and High-Value Use

Steel slag tailings must be treated to eliminate volume instability caused by free Calcium Oxide (f-CaO) and Magnesium Oxide (f-MgO) before they can be sold. Fresh steel slag is unstable; the free lime hydrates and expands upon contact with water, causing road bases to heave and crack if untreated material is used.

The most effective stabilization method is “Steam Aging” or autoclaving. Exposing the slag to hot steam for approximately 12 hours rapidly hydrates the free lime, stabilizing the material much faster than natural aging. Once stable, the slag meets standards for construction aggregates. For higher value applications, the stable tailings can be ground into fine powder using a vertical roller mill or a modified Ceramic Ball Mill. The resulting “Steel Slag Powder” possesses cementitious properties and can be sold to concrete batching plants as a mineral admixture.

Environmental Control: Managing Abrasive Dust

Designing a dust removal system for steel slag requires high air velocity ducts and specialized filter media. Dry processing generates massive amounts of heavy, abrasive dust that can block standard systems. Unlike limestone dust, steel slag dust cuts through standard filter bags and settles in horizontal ducts.

An effective design maintains a duct air velocity of 20-22 m/s to keep the heavy dust in suspension. A spark arrestor (such as a cyclone or gravity settler) must be installed before the baghouse, as crushing steel against steel generates sparks that can ignite filter bags. Furthermore, the filter bags should be coated with PTFE (Polytetrafluoroethylene). This coating prevents the slightly oily and moist slag dust from adhering permanently to the bag, ensuring the pulse-jet cleaning system functions correctly and the plant remains compliant with environmental regulations.

2026 Latest Steel Slag Processing Trends

The steel slag processing industry is trending toward “Zero Discharge” and high-value utilization. In 2026, simple magnetic separation is considered insufficient. The focus has shifted to integrating thermal energy recovery from hot slag and producing ultra-fine slag powder for high-strength concrete. Technological advancements are also prioritizing dry cleaning methods to reduce water treatment costs and environmental impact.

Latest Developments Overview

- [Hot Stage Crushing]: Development of equipment capable of crushing slag while warm to utilize thermal stress for easier breakage.

- [Vertical Milling]: Increasing adoption of vertical mills over traditional ball mills for the energy-efficient production of slag micro-powder.

- [Dry Magnetic Separation]: Implementation of high-intensity dry magnetic separators to replace wet systems, eliminating complex wastewater management.

Successful steel slag processing hinges on the effective separation of metal from mineral and the management of extreme material hardness. Utilizing hydraulic protection on crushers is essential to handle steel ingots, while Rod Mills are crucial for preserving malleable iron. A multi-stage magnetic separation system ensures maximum recovery, and the stabilization of tailings is required to create marketable construction products.

Standard aggregate plants are ill-suited for steel slag and often lead to failure. Contacting ZONEDING for a specialized Industrial Solid Waste Treatment solution is recommended. Hardness testing and iron content analysis are necessary steps to engineer a production line that balances high recovery rates with manageable wear costs.

Zoneding Machine

Zoneding Machine