Placer Gold: The Ultimate Guide to Formation, Types & Mining

3718Ready to find gold? This guide explains how placer deposits form, how to identify different types, and the essential mining methods from panning to sluicing.

View detailsSearch the whole station Crushing Equipment

A search for the “best ball mill machines” often leads to misleading information. For industrial equipment, a simple ranked list is not practical. The optimal ball mill is not determined by brand name alone, but by its precise alignment with your material, capacity requirements, and operational budget. A successful investment is a machine that achieves your target particle size consistently, operates with predictable costs, and maintains high availability for many years.

This guide provides the technical framework our engineers use for proper ball mill selection. It will help you define your requirements and evaluate your options to make a sound financial and operational decision.

Before you even think about a ball mill manufacturer, you must have clear answers about your own project. Answering these questions will guide 90% of your decision-making.

You do not need to be a complex engineer to understand the basics. Think of it this way: the Bond Work Index (BWi) is a number that represents your ore’s toughness. Grinding soft limestone (BWi of 8) is easy. Grinding hard taconite iron ore (BWi of 22) is extremely difficult and energy-intensive.

The rule is simple: Higher BWi or higher tons per hour (tph) requires more power (kW). More power means a larger motor and a larger, more robust mill. A professional ball mill manufacturer like ZONEDING will perform lab tests on your ore sample. We use the BWi and your capacity target to calculate the precise motor power and mill dimensions you need. Trying to use an undersized mill on hard ore is a recipe for failure—you will never reach your production goals.

The purchase price of a ball mill is only the tip of the iceberg. The long-term operational costs (OpEx) are what truly determine your profitability. This is called the Total Cost of Ownership (TCO).

The biggest hidden costs are:

| Cost Factor | Initial View (The Trap) | Reality (The TCO) | Your Strategic Focus |

|---|---|---|---|

| Price | The only thing that matters. | 15-20% of the total cost. | Balance initial price with long-term costs. |

| Energy | Just a utility bill. | 40-50% of TCO. The biggest cost. | Demand an energy-efficient drive and mill design. |

| Wear Parts | A minor detail. | 20-30% of TCO. | Choose durable liners and quality grinding media. |

| Downtime | Not considered. | Can exceed all other costs. | Select a reliable machine designed for easy maintenance. |

This single choice will fundamentally change your entire plant design. It is not a minor preference.

Choosing between them is simple: Let your final product and downstream process dictate the method. To understand the differences in more detail, see our complete guide on Wet vs. Dry Grinding.

The market is generally divided into three tiers. Understanding them helps you align your project’s needs with the right partner.

These are massive multinational corporations. They sell you a complete, guaranteed system, not just a machine. They are the right choice for huge, billion-dollar projects where a performance warranty is essential, and the budget is secondary.

This is where ZONEDING operates. We are manufacturers with deep engineering expertise who offer highly customized, robust, and reliable Ball Mill Machines. We provide excellent value by focusing on core machine quality and tailored solutions without the massive overhead of a global giant. This is ideal for small to large-sized mines and industrial plants that need a high-performance machine at a competitive price.

These are often small workshops or trading companies. They compete on price alone. The risk is high, as they may cut corners on materials, welding quality, and heat treatment, leading to catastrophic failures and no after-sales support.

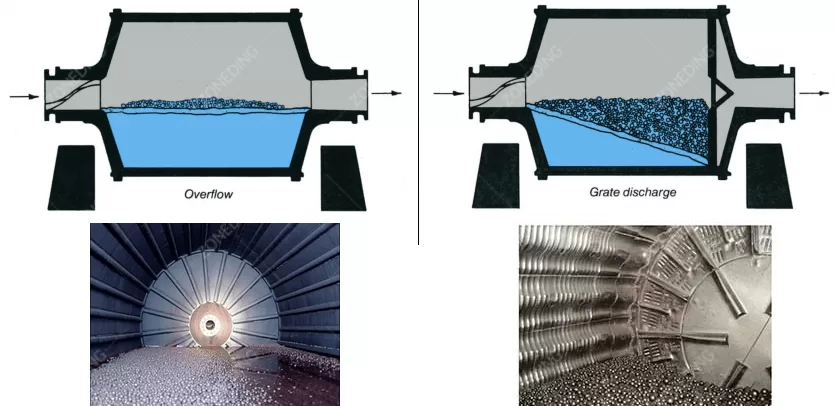

This refers to how the ground material exits the mill.

Your required product fineness (P80) will determine which type is right for your grinding circuit design.

To ensure your investment is future-proof, pay attention to these advancements:

To get a serious, competitive quote, you must provide the right data. A professional ball mill manufacturer will ask for the following. Be prepared.

Having this information ready shows you are a serious buyer and allows us to provide you with a precise and competitive technical and commercial proposal.

Q1: What is the biggest mistake people make when buying a ball mill?

A: Focusing only on the initial purchase price. The biggest cost of a ball mill is not buying it; it’s running it. A cheap, inefficient mill will cost you far more in electricity and downtime over its life than a slightly more expensive, well-engineered machine.

Q2: How long does a ball mill last?

A: The main shell and heads, if built correctly, can last for 30-50 years or more. The internal wear parts (liners and grinding media) are consumables and are replaced periodically. A high-quality mill is a multi-generational investment.

Q3: Can I buy a used ball mill?

A: Yes, but with extreme caution. You must have it professionally inspected for shell thickness, weld integrity, and trunnion roundness. Often, a new, well-priced mill from a reputable manufacturer like ZONEDING offers better long-term value and reliability than a used mill with an unknown history.

There is no “best ball mill machine,” only the right ball mill for your project. The selection process starts not with brands, but with a deep understanding of your own material, process requirements, and financial goals. By answering the key questions in this guide, you move from a confused buyer to an informed investor. You prioritize long-term profitability over short-term price and focus on the factors that truly matter: efficiency, reliability, and Total Cost of Ownership.

Since 2004, ZONEDING MACHINE has specialized in manufacturing robust, efficient, and cost-effective grinding solutions. We don’t just sell machines; we partner with our clients to design the right ball mill for their specific needs. Our engineering team will work with you to analyze your ore and design a grinding circuit that maximizes your productivity and profitability. We have successfully delivered equipment to over 120 countries, proving our commitment to quality and service.

Ready to move beyond generic lists and discuss a real solution for your project? Contact our engineers today to get a professional consultation and a detailed quote based on your unique requirements.

Ready to find gold? This guide explains how placer deposits form, how to identify different types, and the essential mining methods from panning to sluicing.

View detailsThe perfect solution for gold mining. Our portable hard rock crushers are engineered to process gold-bearing ore efficiently.

View detailsCopper sulfide flotation is a standard mineral processing method. However, different ore bodies require specific processing strategies due to variations in mineral composition. As high-grade deposits deplete, the industry now processes more compl...

View detailsDiscover essential gravity separation methods for gold recovery: jigging, spirals, shaking tables, and sluices, boosting mining efficiency.

View details