The Ultimate Guide to Gold Gravity Beneficiation

3542This expert guide details the process of gold gravity beneficiation, helping you optimize equipment settings and techniques for maximum recovery.

View detailsSearch the whole station Crushing Equipment

Placer gold mining is a business of efficiently moving huge volumes of dirt to liberate a tiny fraction of value. Success depends on understanding the geology, using the right placer gold equipment, and focusing on your cost per ton.

This is not a guide about finding a few flakes of gold. This is a guide to understanding the business of moving massive volumes of worthless dirt to liberate the tiny fraction of value within. This guide covers everything from placer gold exploration to designing an efficient gold washing plant.

Placer gold is native gold that has been eroded from a lode deposit and concentrated in a new location by gravity and water. It is easier to mine because it is in loose sand and gravel, requiring no blasting or crushing.

Mining lode gold from a Hard Rock Gold Processing Plant means drilling, blasting, and using massive crushers and Ball Mills. The gold is locked inside solid rock. Placer gold processing is much simpler. The gold is already free, mixed in with loose material. Your job is not to break rocks; it is to separate the heavy gold from the light sand. This means lower capital costs and a much simpler process.

The formation of a placer deposit is a lesson in patience and physics. It is a process that takes millions of years, and a river acts like a giant, lazy sluice box.

Gold is freed from lode deposits by weathering. Rain and rivers transport it downstream. Because gold is extremely dense, it drops out of the current wherever the water slows down, concentrating in “pay streaks.”

This is the single most important fact in all of placer mining: gold is incredibly dense (19.3 g/cm³), while common rock like quartz is light (2.7 g/cm³). As a river tumbles everything downstream, it sorts materials by weight. The light sand and gravel keep moving, but the heavy gold sinks.

Finding gold isn’t about luck; it’s about reading the landscape and understanding where gold is likely to be trapped.

Look for places where water slows down:

A key indicator is the presence of “black sand.” This is a concentration of other heavy minerals like magnetite and hematite. Since they are also dense (though not as dense as gold), they accumulate in the same places. If you find lines of black sand, you are in the right type of environment for placer gold exploration.

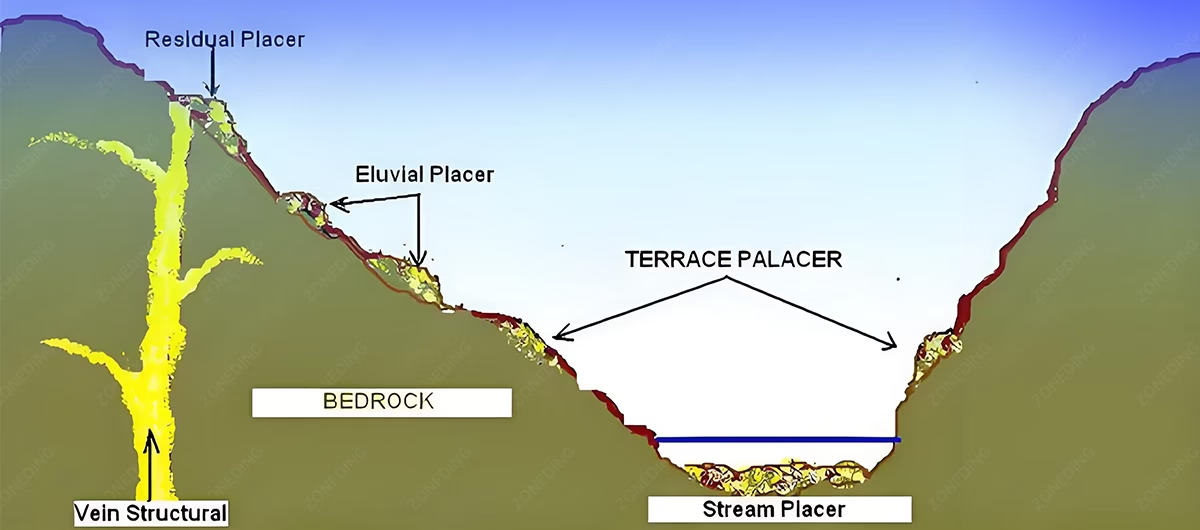

Not all placer deposits are the same. From a miner’s perspective, each type presents a different business opportunity and a unique set of challenges.

| Deposit Type | Description | Miner’s Perspective & Challenge |

|---|---|---|

| Alluvial (Stream) Placers | Gold found in the gravel of existing or ancient rivers. | Bread and butter of the industry. The main challenge is the “overburden”—the worthless gravel you must move to reach the pay streak on the bedrock. Your profit depends on moving this overburden cheaply. |

| Bench Placers | Ancient riverbeds left as terraces high up on a valley side after the river cut a new, deeper channel. | High potential, but high cost. The gold is often far from a water source. The main challenge is logistics: you must either pump massive amounts of water up to the deposit or haul tons of gravel down to the water. |

| Eluvial Placers | Gold that has weathered from a lode but only moved a short distance downhill, not yet in a river. | A prospecting clue, not a production target. The gold is often angular and close to its source. The challenge is that it’s usually dispersed over a wide area, making it difficult to mine economically. |

| Beach Placers | Fine gold concentrated by wave action on a beach, often in lines of black sand. | A specialized game. The deposit is constantly moving with tides and storms. It requires equipment specifically designed for fine gold recovery, and operations must be mobile. |

Before you invest in a full plant, you must test the ground. This initial gold panning and prospecting phase is essential for verifying the value of a deposit.

These tools are for prospecting, not production. Their purpose is to collect samples and determine the average grade of the pay dirt.

Once you have proven a deposit, it is time to scale up. A commercial placer gold processing plant is designed for one thing: volume. The typical process flow uses gravity separation at every stage.

This combination of robust, high-volume equipment forms the core of a modern Gold Processing Plant.

You can have the richest ground in the world and still go bankrupt. Success in placer gold mining comes from avoiding two cardinal sins.

The Sin of Ignoring Volume: Your profit is NOT determined by the grams-per-ton in your best pay streak. It is determined by the average grade of all material you process, multiplied by your processing volume, minus your total operating cost. A successful operation is a dirt-moving business first and a gold business second. Focus on your cost-per-ton to move material.

The Sin of Chasing Fine Gold: Many operators become obsessed with recovering 100% of the gold, especially the microscopic “flour gold.” The reality is that 80-95% of the value is often in the larger gold particles that are easily caught. Chasing that last 5% can double your equipment cost and halve your processing volume. You will go broke “efficiently.”

Focus on a simple, robust plant that maximizes tonnage. Move the dirt, bank the profitable gold, and don’t cry over the dust.

Large-scale mining is a dirt-moving business. Efficiency and volume are everything. The plant must be designed to process hundreds of tons per hour with minimal downtime.

A large-scale gold washing plant is built for high throughput and recovery of a wide range of gold sizes. It often includes a trommel, multiple recovery stages with jigs and sluices, and a final concentrate circuit with Centrifugal Concentrators and shaking tables.

The placer gold processing flowsheet is optimized for the specific deposit.

You can have the richest ground and the best equipment in the world and still go bankrupt. Placer mining is an operational challenge. Success is in the details.

The most critical factors are the percentage of clay in the feed, water availability and management, and the efficiency of your material handling. Overlooking any of these can crush your recovery rates and profitability.

It is the things around the equipment that often determine success.

After all that work, you do not have a gold bar. You have a bucket of heavy mineral concentrate with gold in it. The final step is to separate the gold from this last bit of sand.

The gold concentrate is first upgraded on a shaking table to remove the last of the black sand. The nearly pure gold is then dried and melted in a furnace with flux to remove any remaining impurities, before being poured into a mold to create a gold bar.

This is the final, satisfying step in the process.

Since 2004, ZONEDING has engineered and manufactured complete solutions for the mining industry. We specialize in designing and building robust, high-efficiency Placer Gold Mining plants. We understand that profitability comes from moving volume reliably. Our factory-direct model allows us to provide custom-designed trommels, jigs, shaking tables, and complete wash plants that are built for the harsh realities of the field. We have delivered profitable solutions to miners in over 120 countries.

If you are evaluating a placer gold project, contact us. Let our engineers help you design a plant that is built for one purpose: to make you money.

This expert guide details the process of gold gravity beneficiation, helping you optimize equipment settings and techniques for maximum recovery.

View detailsOptimize jaw crusher maintenance. Prevent breakdowns, maximize uptime, and ensure consistent, high-efficiency crushing with our practical guide.

View detailsGet gold concentrates with the right equipment. Discover the 8 essential machines for placer & hard rock gold mining, and learn the secret to fine gold recovery.

View detailsReliability defines the value of mining equipment. True durability results from correct configuration rather than just brand reputation. A machine functioning well in limestone applications may fail rapidly in granite operations. Equipment select...

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy