High-Purity Kaolin Processing: A Guide from Mine to Market

3733A complete guide to the kaolin mining process. Learn every step from raw material extraction to achieving high-purity kaolin using best industry practices.

View detailsSearch the whole station Crushing Equipment

Choosing the wrong crusher is a multi-million dollar mistake. You are facing a wall of technical specifications but have no clear guide on what actually works for your specific rock and business goals.

A crusher is a machine designed to break large rocks into smaller pieces. The main types are Jaw, Cone, and Impact crushers, each used for different stages of crushing and types of material, from hard granite to soft limestone and recycling.

With many years of collective engineering experience, ZONEDING has designed and commissioned Crushing Plants worldwide. We’ve seen projects succeed brilliantly and fail spectacularly. The difference always comes down to making the right choice at the start. You are not just buying a machine; you are choosing a process. Let’s walk through what you absolutely need to know.

You think a crusher’s job is just to make small rocks out of big ones. That’s a dangerous oversimplification. The real job is to be the primary engine of your operation’s profitability.

A crusher is a heavy-duty machine that applies mechanical force to break down blocks of stone, ore, or waste material. It is the first and most critical step in producing aggregates, liberating valuable minerals, and recycling materials.

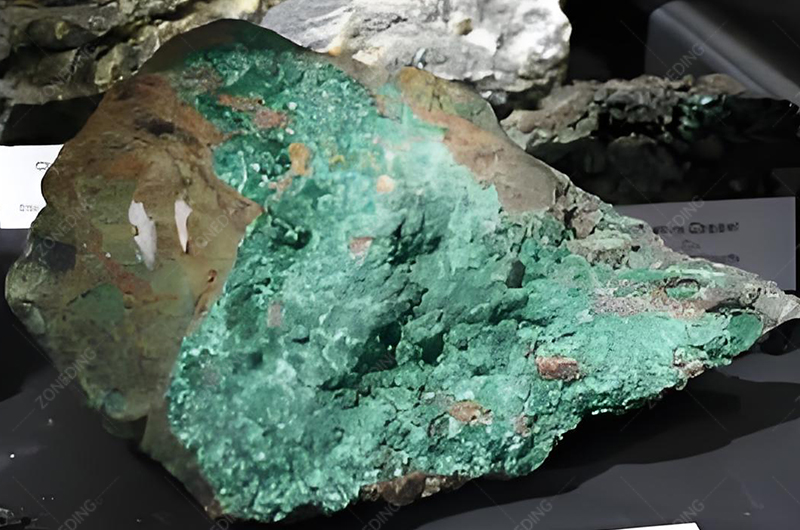

A Stone Crusher is the heart of any quarry or mine site. Its function is foundational. In the aggregate industry, it creates the specific sizes and shapes of stone needed for concrete and asphalt. Without crushers, we could not build roads, bridges, or buildings. In mining, an Ore Crusher performs the first step of liberation. It breaks down the raw ore to a size where the valuable minerals (like gold or copper) can be separated from the waste rock in the downstream Beneficiation Equipment. In the recycling sector, crushers break down concrete and asphalt from old construction sites, turning waste into reusable products. The efficiency and reliability of your crusher directly determine the productivity and profitability of your entire site.

| Function | Industry Application | End Product |

|---|---|---|

| Size Reduction | Aggregates & Quarrying | Sized sand and gravel for construction. |

| Mineral Liberation | Mining (Gold Processing Plant, Copper Processing) | Crushed ore ready for grinding and separation. |

| Recycling | Construction & Demolition | Recycled aggregate for road base and fill. |

You have a pile of rock, but is it profitable to crush? Using the wrong machine on the wrong material is the fastest way to destroy your equipment and your budget.

Crushers are used for hard rock like granite, softer rock like limestone, mined ores, and recycling materials like construction waste. Their applications span quarrying, mining, and environmental industries.

The most important decision in Crusher selection is matching the machine’s operating principle to your material’s properties. There are two fundamental ways to break a rock: squeezing it or hitting it. A Hard rock crusher, like a Jaw Crusher or Cone Crusher, uses compression force. This is ideal for very hard, abrasive materials like granite, basalt, or river stone. An impact-style crusher, like an Impact Crusher, uses high-speed impact. This is perfect for less abrasive, medium-to-soft materials like limestone or a Construction waste crusher. Using an impact crusher on hard, abrasive granite will result in incredibly high Wear parts cost and downtime, destroying your profit margin. This fundamental choice between compression and impact is the first question you must answer correctly.

| Material Type | Hardness / Abrasiveness | Recommended Crushing Principle |

|---|---|---|

| Granite, Basalt, River Stone | Very Hard & Abrasive | Compression (Squeezing) |

| Limestone, Dolomite | Soft to Medium Hard & Low Abrasiveness | Impact (Hitting) |

| Iron Ore, Copper Ore | Variable Hardness & Abrasiveness | Primarily Compression |

| Construction & Demolition Waste | Low Hardness & Abrasiveness | Primarily Impact |

Crushing happens in stages: Primary (coarse), Secondary (medium), and Tertiary (fine/sand making). A Jaw Crusher is a typical Primary crusher. A Cone Crusher is for secondary. A VSI Sand Maker is for tertiary.

No single crusher can take a 1-meter boulder and turn it into 5mm sand. The process is a gradual reduction circuit with different machines optimized for each stage.

1. Primary Crushing

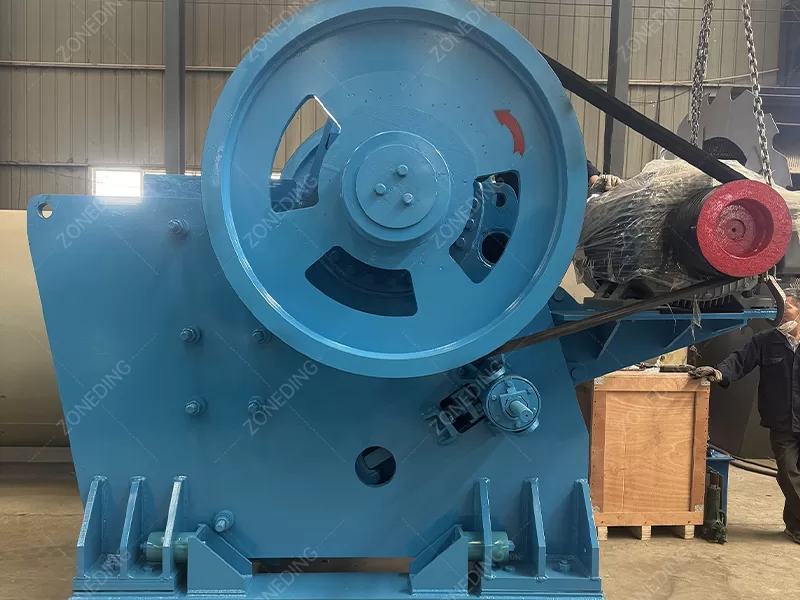

This is the first stage. It takes the largest rocks directly from the mine or quarry and breaks them down to a size that can be handled by the next stage, typically around 150-300mm. The undisputed king of primary crushing is the Jaw Crusher due to its large feed opening and robust design.

2. Secondary Crushing

This stage takes the output from the primary crusher and reduces it further, typically down to 10-40mm. The most common Secondary and tertiary crushers are the Cone Crusher (for hard rock) and the Impact Crusher (for softer rock).

3. Tertiary Crushing (Sand Making)

This final stage takes the output from the secondary crusher and shapes it into high-quality manufactured sand or fine, cubical aggregate. The specialized machine for this is the Sand making machine, also known as a VSI. For flexibility, many operations use a Mobile crushing station that can combine these stages.

The sales brochure makes every crusher look like the perfect solution. But using the wrong one for your specific job will lead to high costs, low output, and poor product quality.

Use a Jaw for primary crushing. Use a Cone for secondary crushing of hard, abrasive rock. Use an Impact for secondary crushing of softer rock or for shaping. Use a VSI for making sand and achieving the best particle shape.

Choosing the right machine is about understanding its strengths and weaknesses.

The Jaw Crusher: The Primary Workhorse

The Jaw crusher is the starting point for almost every rock crushing plant. It uses compression to break large rocks. Its strength is its simplicity and durability. It can handle a wide variety of materials and is relatively low in maintenance. It is designed purely for size reduction, not for creating a specific product shape.

The Cone Crusher: The Hard Rock Specialist

The Cone crusher is the champion for processing hard and abrasive materials in the secondary and tertiary stages. It also uses compression but in a circular motion. To work efficiently, it must be “choke-fed”—kept full of material. This promotes rock-on-rock crushing, which maximizes throughput and produces a better-shaped product while protecting the machine’s wear parts.

The Impact Crusher: The Shaping Specialist

The Impact crusher works by throwing rocks at high speed against breaker plates. This method excels at producing a highly cubical, high-quality product shape, which is essential for modern concrete and asphalt specifications. However, it is best suited for non-abrasive materials like limestone. Using it on granite will lead to extremely high Wear parts cost.

The VSI Sand Maker: The Final Touch

The Vertical Shaft Impactor, or VSI sand maker, is the ultimate shaping tool. It throws rock against rock at very high speeds. It’s used in the final stage of crushing to turn problematic flaky aggregate into premium, cubical manufactured sand. It is a “shaping machine” more than a reduction crusher.

Your customer rejected a load of aggregate because it was too “flaky” and “elongated.” You met the size specification, but the shape was wrong, and your profit just disappeared.

Yes, absolutely. The type of crusher fundamentally determines the product shape. Impact crushers (Impact Crusher, VSI) produce a superior, cubical shape. Compression crushers (Jaw Crusher, Cone Crusher) tend to produce more flaky, elongated particles.

The final Aggregate particle shape is one of the most critical quality factors, and it is a direct result of the crushing method. A high-quality cubical aggregate has fewer voids when mixed into concrete or asphalt. This means you need less of the expensive binder (cement or bitumen) to create a strong final product. This is a huge cost saving for your customer and makes your product more valuable. Impact crushing works like hitting a rock with a hammer; it tends to break along its natural cleavage planes, resulting in a more cubical shape. Compression crushing squeezes the rock until it fractures. This fracture is less controlled and often results in flat or elongated pieces. That is why a modern, high-spec aggregate plant often uses a VSI in the final stage—specifically to correct the shape of material produced by cone crushers.

| Crusher Type | Crushing Principle | Typical Product Shape | Value in Market |

|---|---|---|---|

| Jaw Crusher | Compression | Flaky & Elongated | Low |

| Cone Crusher | Compression | Flaky (improves with choke feed) | Medium |

| Impact Crusher | Impact | Good & Cubical | High |

| VSI Sand Maker | High-Speed Impact | Excellent & Cubical | Premium |

You call a supplier for a quote, but you can’t answer their basic questions. You get a generic, overpriced recommendation that isn’t tailored to your needs, wasting everyone’s time.

Before you call, you must know your material type and hardness, the maximum size of your feed rock, your target Output size, and your required Crusher capacity in tons per hour.

As a manufacturer, ZONEDING can only provide a truly optimized and cost-effective solution if you provide us with the right data. The more detailed your information, the better the solution will be. Coming prepared for this conversation will save you time and money and ensure you get a machine that is perfectly suited for your project. A generic solution is never the most profitable one. Before you even think about the Crusher price, you need to define your project with as much detail as possible. This information forms the basis of any intelligent Crusher selection process. ZONEDING has created a simple checklist to help you prepare.

| Information Needed | Why It’s Critical | Example |

|---|---|---|

| Material Type | Determines crusher principle (Compression vs. Impact). | “Hard Granite with high Silica content” |

| Max Feed Size | Sets the required opening for the primary crusher. | “Boulders up to 800mm” |

| Target Output Sizes | Defines the number of stages and types of crushers needed. | “0-5mm, 5-10mm, 10-20mm” |

| Required Capacity | Determines the size and model of the crushers. | “400 tons per hour” |

| Material Issues | Clay or moisture can cause clogging and require specific solutions. | “High moisture, 15% clay content” |

Q1: How much does a crusher cost?

A: The price varies dramatically based on type, size, and manufacturer. A small Jaw Crusher might be a fraction of the cost of a large, high-capacity Cone Crusher. The price is determined by the machine’s weight, technology, and the quality of its components. Remember, the initial purchase price is only part of the equation. You must also consider the long-term operational costs, especially the Wear parts cost, which is why choosing the right type for your material is so critical.

Q2:What is a closed-circuit crushing system?

A: A closed-circuit system is the professional way to guarantee your final product size. It consists of a crusher and a Vibrating Screen working together. The material goes from the crusher to the screen. The correctly sized material (the final product) is screened out. Any oversized material is sent back to the crusher on a return conveyor for another round of crushing. This “loop” ensures that no oversized product gets into your final stockpile, guaranteeing quality and maximizing the efficiency of your crusher.

Q3: Why is the silica (SiO₂) content of my rock so important?

A:Silica (found in quartz) is basically microscopic, razor-sharp glass. It is extremely abrasive. The higher the silica content in your rock (like in granite or hard river stone), the faster it will wear down your crusher’s liners, blow bars, or hammers. This is the single most important factor when considering an Impact Crusher. For high-silica rock, a compression crusher like a cone crusher is almost always the more economical choice due to its much lower wear costs. Always get a geological report on your material before you buy a crusher.

Q4: Should I choose a mobile crusher or a stationary plant?

A: This depends on your business model. A stationary plant is built for long-term, high-volume production in one location, like a large quarry. It generally has a lower cost per ton in the long run. A Mobile Stone Crusher offers incredible flexibility. It is ideal for contractors who move from job to job, for working in multiple locations within a single large mine, or for shorter-term projects. The biggest advantage of a Mobile Crusher is not just moving between sites, but reducing hauling costs by crushing material directly at the excavation face.

Q5: What is the most important part of crusher maintenance?

A: All maintenance is important, but the most critical aspect is consistent monitoring and management of wear parts. This means regularly checking the jaw plates, cone liners, or impactor blow bars. Running a crusher with worn-out parts is inefficient, produces a poor-quality product, and can cause catastrophic damage to the machine itself. Set up a regular inspection schedule, keep spare wear parts on hand, and listen to your machine. Changes in sound can often tell you something is wrong before it becomes a major failure.

Choosing the right crusher is about matching the machine to your rock, your product goals, and your business plan. It’s a system, not just a single piece of equipment.

A complete guide to the kaolin mining process. Learn every step from raw material extraction to achieving high-purity kaolin using best industry practices.

View detailsOur complete guide walks you through the process of iron removal from kaolin clay. Boost whiteness and quality for industrial applications like ceramics.

View detailsProcessing tin ore (Cassiterite) might appear straightforward due to its significant weight. However, decades of industry experience demonstrate that high specific gravity is deceptive. Cassiterite is fragile and shatters easily. Without a precis...

View detailsLearn exactly how silver mining works with our step-by-step guide. We break down the complete process, from ore exploration and mining to final refining.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy