Search the whole station Crushing Equipment

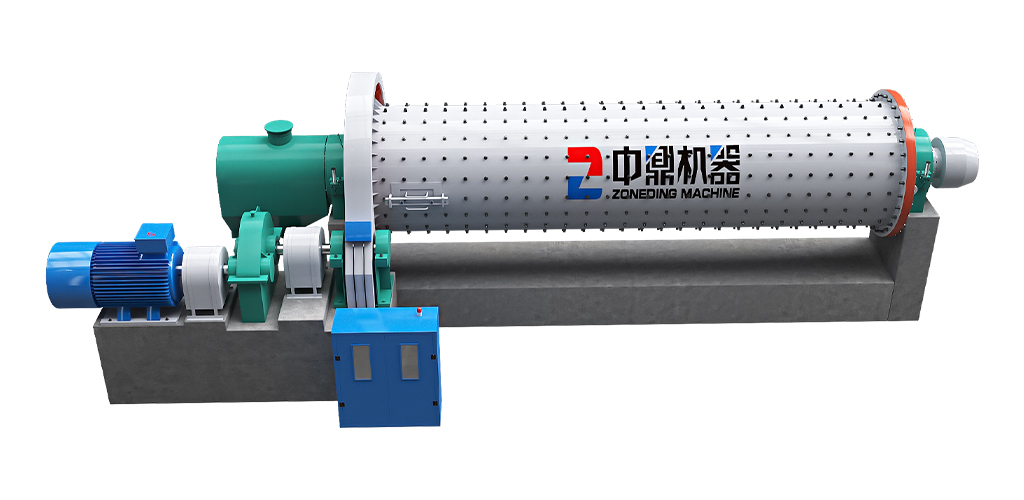

A ball mill is a cylindrical rotating device with steel balls or other grinding media inside. It crushes and grinds the ore through the impact force, friction, and gravity generated by the rotation of the cylinder.

The ball mill is a crucial grinding device widely utilized across multiple industrial sectors, including cement, silicate products, novel construction materials, refractory materials, fertilizers, ferrous and non-ferrous metal ore dressing, as well as glass and ceramics manufacturing. Its fundamental operating principle lies in the utilization of grinding bodies within the mill cylinder (such as steel balls, rods, or other shaped media) that impact, compress, and grind the materials during rotational motion, effectively reducing them to the desired particle size.

A ball mill is a grinding machine designed to grind hard materials into a fine powder. It is a large horizontal cylinder that rotates on its axis. We fill the cylinder with the material you need to grind, along with a grinding media. This media is usually made of hard steel or ceramic balls. As the cylinder turns, the balls are lifted and then fall, crushing and grinding the material trapped between them. This process is very effective for creating a uniform, fine product. It is a trusted technology that has been used for many decades in demanding applications.

Ball mill is perfect when you need to turn a crushed material into an extremely fine powder. Its main job is to reduce particle size down to the micron level. This makes it an essential tool for processes where the final product’s quality depends on its fineness. A primary example is in a cement plant, where a cement mill is used to grind clinker. The ball mill for cement grinding is crucial for achieving the correct fineness. Other major uses include the mining industry, where it frees valuable minerals from ore, and the ceramics industry, for preparing raw materials.

The working principle of a ball mill is simple but effective. It relies on impact and attrition. First, you feed the material into the hollow cylinder. Inside, hard grinding balls fill about 30-40% of the space. A powerful motor makes the cylinder rotate. The rotation lifts the balls and the material up the side of the shell. When they reach a certain height, gravity makes them fall. This cascading motion creates a powerful crushing force. The impact of the balls breaks down coarse particles. At the same time, the rubbing action between the balls, liners, and material grinds everything even finer. The fine powder then exits the mill.

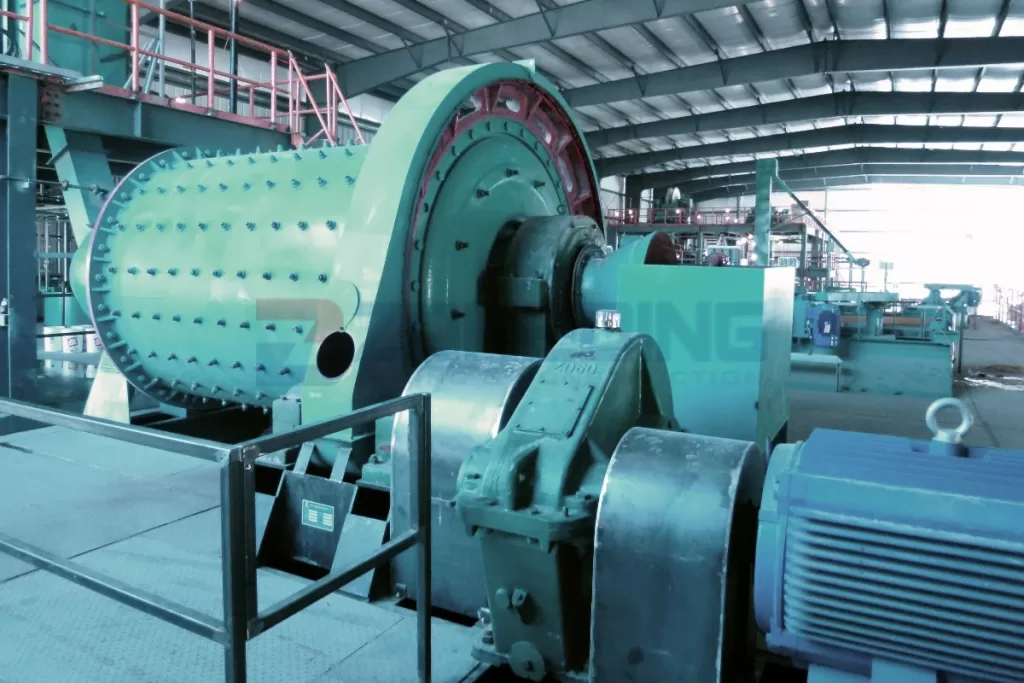

You should choose a ball mill because it is incredibly versatile and reliable for fine grinding. It can handle a wide range of materials, from very hard ores to softer chemicals. A key advantage is its ability to operate in both wet and dry conditions, making it suitable for many different processes. The ball milling process produces a very consistent and fine product, which is often a strict requirement. These machines are also very robust. They are built for continuous, heavy-duty operation with a simple design that is easy to maintain. This combination of effectiveness, flexibility, and durability makes the ball mill a superior choice for many grinding tasks.

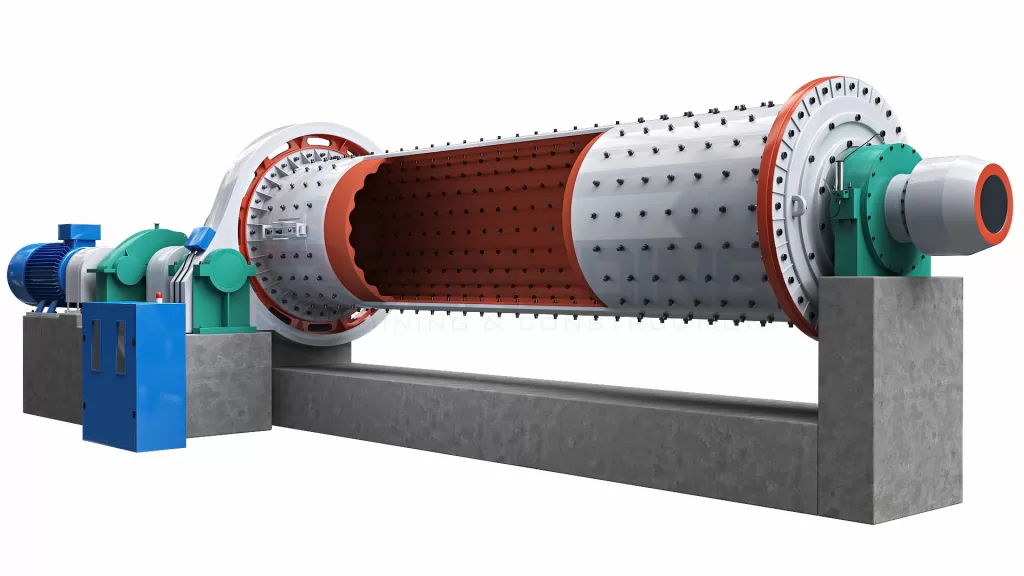

The structure of ball mill mainly consists of cylinder, end caps, bearings, big gear, feeding device, discharging device, and grinding media (such as steel balls or ceramic balls) inside.

Its working principle is that the material enters the cylinder through the feeding device, and the cylinder rotates driven by the transmission device. The grinding media inside the cylinder subject the material to intense impact and friction due to centrifugal force and friction, crushing and grinding the material. After a certain period of time, the material grinded to the desired particle size is discharged through the discharging device.

There are several types of mills used for grinding, but ball mills are a major category. Within ball mills, the main difference is how they discharge the material. This choice affects the efficiency and the final product. The two most common types are the grate type and the overflow type. The grate type has a slotted diaphragm at the end, which controls the size of the exiting material and prevents over-grinding. The overflow type is simpler; the material slurry flows out once it reaches a certain level. At ZONEDING, we help you choose the best type for your specific needs, whether it’s a ceramic ball mill or a large mining mill.

A modern ball mill has features designed for high performance and long life. The main body, or shell, is made from thick, high-strength steel plates. Inside, the shell is protected by replaceable wear-resistant liners. These liners are not just for protection; they have lifter bars that are crucial for lifting the grinding media efficiently. The drive system is powerful and reliable, consisting of a large girth gear, a pinion, a gearbox, and a high-efficiency motor. Our mills at ZONEDING also feature robust, oversized bearings to support the heavy rotating load smoothly. These features ensure that the ball mill machine can run continuously for long periods with minimal issues.

The price of a ball mill varies greatly. A small, simple ball mill homemade for a lab might be inexpensive, but an industrial ball mill can cost from tens of thousands to over a million dollars. The final price depends on its size, capacity, construction materials, and brand. However, the initial purchase price is only part of the story. You must also consider the total cost of ownership. This includes major ongoing costs like energy consumption and replacing the grinding media in ball mill. At ZONEDING, we focus on efficiency to lower your energy bills. We also use high-quality components to reduce maintenance needs, which saves you money in the long run.

A ball mill grinder is very versatile and can process a huge variety of materials. Its powerful grinding action works on both hard and soft substances. In the mining industry, it is used to grind ores like gold, copper, iron, and lead. For construction materials, it is essential for grinding cement clinker, slag, and limestone. The chemical industry uses it to produce fine powders of pigments, fertilizers, and other compounds. It is also a key machine in the ceramics industry, where it grinds raw materials like quartz, feldspar, and clay. This flexibility makes the ball mill a fundamental tool for many material processing operations.

Understanding the key components of a ball mill helps you appreciate its robust design. The main part is the rotating shell, a large steel cylinder. Inside the shell are liners, which are replaceable plates that protect the shell from wear. These liners have lifter bars that play a critical role in lifting the grinding media. Worn lifter bars can seriously reduce the mill’s efficiency. The ball mill media consists of steel or ceramic balls that do the actual grinding. At each end are trunnions, which are hollow shafts that allow material to enter and exit. These trunnions are supported by large bearings. Finally, the drive system provides the power to turn the mill.

The mobile ball mill has the characteristics of convenient transportation and usage in different sites. Compared with the traditional fixed-position ball mill, it is more flexible in use. It is suitable for operations such as ore grinding and building material processing in different sites, which can improve production efficiency and reduce material transportation costs and time.

If you are interested in ball mill, please feel free to contact us! We will provide you with more than two solutions for you to choose from.

| Model | Rotate speed (r/min) | Grinding media Weight (T) | Feed size (mm) | Discharge size (mm) | Capacity (t/h) | Motor power (KW) | Weight (T) |

| Φ900×1800 | 36 | 1.5 | ≦20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.5 |

| Φ900×3000 | 38 | 2.7 | ≦20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.7 |

| Φ1200×2400 | 36 | 3 | ≦25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| Φ1200×3000 | 36 | 3.5 | ≦25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| Φ1200×4500 | 36 | 5 | ≦25 | 0.074-0.4 | 11.6-5.8 | 55 | 13.8 |

| Φ1500×3000 | 32.4 | 7.5 | ≦25 | 0.074-0.4 | 2-5 | 75 | 16.8 |

| Φ1500×4500 | 29.7 | 11 | ≦25 | 0.074-0.4 | 3-6 | 110 | 21 |

| Φ1500×5700 | 27 | 12 | ≦25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Φ1830×3000 | 25.4 | 11 | ≦25 | 0.074-0.4 | 4-10 | 130 | 29 |

| Φ1830×4500 | 25.4 | 15 | ≦25 | 0.074-0.4 | 4.5-12 | 155 | 35.5 |

| Φ1830×6400 | 24.1 | 21 | ≦25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Φ1830×7000 | 24.1 | 23 | ≦25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Φ2100×3000 | 23.7 | 15 | ≦25 | 0.074-0.4 | 6.5-36 | 155 | 34.8 |

| Φ2100×4500 | 23.7 | 24 | ≦25 | 0.074-0.4 | 8-43 | 245 | 42 |

| Φ2100×7000 | 23.7 | 26 | ≦25 | 0.074-0.4 | 8-48 | 280 | 56.6 |

| Φ2200×4500 | 21.5 | 27 | ≦25 | 0.074-0.4 | 9-45 | 280 | 51.8 |

| Φ2200×6500 | 21.7 | 35 | ≦25 | 0.074-0.4 | 14-26 | 380 | 60 |

| Φ2200×7000 | 21.7 | 35 | ≦25 | 0.074-0.4 | 15-28 | 380 | 62 |

| Φ2200×7500 | 21.7 | 35 | ≦25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Φ2400×3000 | 21 | 23 | ≦25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Φ2400×4500 | 21 | 30 | ≦25 | 0.074-0.4 | 8.5-60 | 320 | 69 |

| Φ2700×4000 | 20.7 | 40 | ≦25 | 0.074-0.4 | 12-80 | 380 | 94 |

| Φ2700×4500 | 20.7 | 48 | ≦25 | 0.074-0.4 | 12-90 | 480 | 102 |

| Φ3200×4500 | 18 | 65 | ≦25 | 0.074-0.4 | 25-120 | 630 | 137 |

| Φ3600×4500 | 17 | 90 | ≦25 | 0.074-0.4 | 25-140 | 850 | 158 |

| Φ3600×6000 | 17 | 110 | ≦25 | 0.074-0.4 | 25-160 | 1250 | 175 |

| Φ3600×8500 | 18 | 131 | ≦25 | 0.074-0.4 | 45.8-256 | 1800 | 252 |

| Φ4000×5000 | 16.9 | 121 | ≦25 | 0.074-0.4 | 45-208 | 1500 | 203 |

| Φ4000×6000 | 16.9 | 146 | ≦25 | 0.074-0.4 | 65-248 | 1600 | 218 |

| Φ4000×6700 | 16.9 | 149 | ≦25 | 0.074-0.4 | 45-252 | 1800 | 238 |

| Φ4500×6400 | 15.6 | 172 | ≦25 | 0.074-0.4 | 54-306 | 2000 | 280 |

Our Rod Mill are available in different styles and numerous model sizes in each style to adapt to various grinding requirements. The rod mill is a grinding equipment that uses steel rods as the grinding media, wid…

Our Ceramic ball mill are available in different styles and numerous model sizes in each style to adapt to various grinding requirements. Ceramic ball mill, as a grinding tool for modern refinement industry, stand…

Our Flotation Machine are available in different styles and numerous model sizes in each style to adapt to various mineral separation requirements. A flotation machine is a crucial piece of equipment used to separ…

Magnetic Separator is used to efficiently separate magnetic particles from non-magnetic materials in mineral processing, featuring a rotating drum design and customizable magnetic field strength for high-purity separation. …

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy