Spodumene to Lithium Concentrate: A Complete Processing Guide

3790Explore the complete process of converting spodumene ore into high-grade lithium concentrate. Covers all vital steps, from crushing to final beneficiation.

View detailsSearch the whole station Crushing Equipment

Feldspar is a critical mineral. It serves as a fundamental raw material. It is vital for ceramics, glass, and filler industries. High-quality Feldspar is essential. This equipment helps transform raw ore into high-value products. This guide provides insights into optimizing your feldspar crushing and grinding operations. It helps ensure superior product quality and efficiency.

Feldspar is an aluminosilicate mineral. It is abundant in the Earth’s crust. Its unique properties make it indispensable. It is used in ceramic bodies, glazes, and glass production. Feldspar acts as a flux. It lowers melting temperatures. It improves product strength and durability. However, raw feldspar ore requires extensive processing. This process converts it into a usable form. This processing involves significant challenges. These challenges include achieving high purity. They also include maintaining specific particle size distributions. The market for feldspar demands increasingly strict quality standards. This creates both challenges and significant opportunities.

The primary challenge in feldspar processing involves removing impurities. These impurities include iron-bearing minerals, quartz, and mica. Even trace amounts of iron can discolor ceramic and glass products. This significantly reduces their market value. Another challenge lies in controlling particle size. Different industries require varied particle fineness. Ceramic glazes need ultra-fine powders. Glass manufacturing uses coarser grades. Over-grinding wastes energy. It also generates excessive fines. These can lead to processing difficulties. Additionally, feldspar has moderate hardness. This causes wear on equipment. This wear requires careful selection of wear parts and maintenance strategies. Despite these challenges, advanced processing techniques offer opportunities. They help produce high-quality feldspar. This product commands premium prices. It also opens new markets for specialized applications.

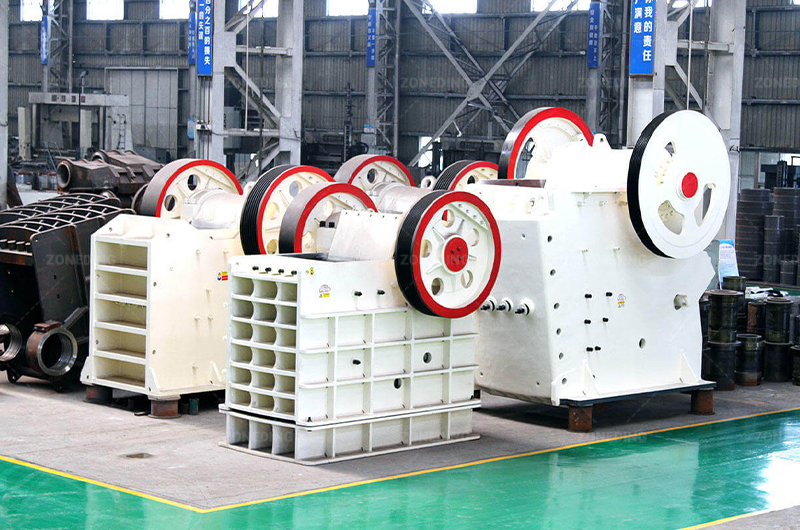

Primary crushing is the first step. It reduces large raw feldspar ore chunks. It transforms them into smaller, manageable sizes. This stage is crucial. It prepares the material for subsequent grinding processes. Efficiency at this stage directly impacts overall plant throughput. It also affects the lifespan of downstream equipment. Choosing the right primary crusher ensures optimal performance. It also helps minimize operational costs.

For primary crushing of feldspar, jaw crushers are typically the preferred choice. They handle large feed sizes effectively. They also possess high reduction ratios. The robust construction of jaw crushers allows them to withstand tough feldspar ore. Their simple design makes them easy to maintain. This minimizes downtime. When selecting a jaw crusher, material properties are key. These include feldspar’s hardness, abrasiveness, and maximum lump size. These properties dictate the crusher’s size and specific model. The objective at this stage is to achieve a uniform discharge size. This prepares the material for secondary crushing. An efficient primary crusher significantly reduces the burden. It protects subsequent crushing and feldspar grinding stages. It also helps in initial liberation of some impurities. This is particularly useful for further beneficiation.

After primary crushing, secondary and tertiary stages follow. These stages are critical. They reduce feldspar to finer, more precise sizes. This prepares the material for efficient feldspar grinding. Precise control over particle size and shape is the main goal. This control directly impacts the quality of the final product. Different types of crushers are employed in these stages. Each type offers specific advantages.

For secondary crushing, cone crushers are widely used. They excel at producing a cubical product shape. This is beneficial for subsequent grinding. Cone crushers offer high throughput. They also have excellent crushing ratios. The type of cone crusher chosen depends on the required output fineness. It also depends on capacity. For tertiary crushing, or fine crushing, impact crushers (like VSI crushers) are effective. They achieve precise particle size distribution. They also produce excellent particle shapes. VSI (Vertical Shaft Impact) crushers are particularly adept. They produce cubical feldspar particles. This is highly desirable for ceramic raw material and glass raw material. Their working principle is “rock-on-rock” or “rock-on-metal”. This minimizes direct contact between metal parts and the feldspar. This significantly reduces iron contamination. Careful selection of liners and rotors is still important. It ensures minimal impurity introduction. This multi-stage crushing process ensures the feed to the grinding circuit is optimized. It enhances overall efficiency and product quality.

Feldspar grinding is a critical step. It achieves the final desired fineness. This stage prepares feldspar for its various industrial applications. The choice of grinding equipment directly impacts energy consumption. It also affects wear part costs. More importantly, it influences the quality of the final product. Different mills are suitable for different fineness requirements.

For feldspar grinding, ball mills are a traditional and versatile choice. They can achieve a wide range of fineness. This ranges from coarse to fine powder. When using ball mills for feldspar, particular attention must be paid. It involves using non-ferrous grinding media and liners. Ceramic balls (like high-alumina balls) and ceramic or rubber liners prevent iron contamination. While this might increase grinding time or energy use, it is indispensable for high-purity feldspar. For large-scale production requiring ultra-fine powder, vertical roller mills (VRM) are an excellent option. VRMs combine crushing, grinding, drying, and classifying in one unit. They offer lower energy consumption. They also have a smaller footprint. They are particularly advantageous when feldspar has higher moisture content. Their drying capability can significantly reduce processing costs. Raymond mills are also used for medium-fine grinding. They are suitable for fineness up to 400 mesh. The selection balances fineness requirements, capacity, energy efficiency, and impurity control.

Producing high-quality feldspar powder involves more than just grinding. It requires precise classification. It also demands efficient impurity removal. These auxiliary steps are vital. They ensure the final product meets stringent purity standards. They also guarantee uniform particle size distribution. Without these processes, even well-ground feldspar may not be marketable.

Efficient classifiers are essential for separating feldspar particles. They sort particles by size. High-efficiency air classifiers are commonly employed. They handle the fine powders from feldspar grinding. These classifiers ensure accurate cut points. They help achieve a narrow particle size distribution (PSD). This is crucial for applications like ceramic glazes. The D50 and D97 values are precisely controlled. This ensures product consistency. For impurity removal, magnetic separators are indispensable. Multi-stage magnetic separation is crucial. It minimizes iron content. This includes dry magnetic separators for coarse fractions. It also includes high-intensity wet magnetic separators for fine powders. Wet magnetic separators are particularly effective. They remove even weakly magnetic iron-bearing minerals. Sometimes, wet beneficiation techniques are necessary. Scrubbers remove clay and surface impurities. Flotation processes separate feldspar from quartz or mica. This comprehensive approach ensures the highest purity. It also provides uniformity for the final feldspar powder.

An efficient and smart production line integrates various feldspar processing equipment seamlessly. This integration is key. It maximizes operational efficiency. It also ensures consistent product quality. A well-designed production line minimizes bottlenecks. It also optimizes energy consumption. It reduces human intervention. Modern production lines incorporate automation and monitoring systems. These elements enhance overall performance.

The integration of feldspar crushing and feldspar grinding equipment forms a comprehensive crushing and grinding production line. This line often begins with primary crushing using a jaw crusher. It then moves to secondary and tertiary crushing with cone crushers or VSI crushers. Conveyor belts link these stages. They ensure smooth material flow. After crushing, the material feeds into a ball mill or vertical roller mill for grinding. High-efficiency classifiers are always in a closed circuit with the grinding mill. They ensure precise particle size control. Magnetic separators are strategically placed throughout the line. They remove iron impurities. Automated control systems monitor key parameters. These parameters include feed rate, motor current, and product fineness. They make real-time adjustments. This optimizes the entire process. This integrated approach not only boosts throughput. It also reduces labor costs. It enhances safety. It provides consistent, high-quality feldspar products.

Investing in feldspar processing equipment requires careful consideration. The goal is to maximize Return on Investment (ROI). Many factors influence this. These factors go beyond the initial purchase price. They include long-term operational costs. They also include product market value. A strategic approach to equipment selection ensures profitability.

Several key factors influence the ROI. First, raw material characteristics are paramount. These include ore hardness, abrasiveness, mineralogy, and impurity levels. A detailed analysis guides equipment choice. It impacts wear parts consumption. It also affects beneficiation requirements. Second, target product specifications are crucial. This includes required fineness, purity (especially iron content), and particle shape. Higher purity and finer products often command higher prices. However, they also require more advanced, and potentially costlier, equipment. Third, production capacity is a direct driver of revenue. Matching equipment capacity to market demand prevents over-investment or under-utilization. Fourth, energy consumption is a major operating cost. Selecting energy-saving crushing and grinding equipment significantly improves long-term ROI. Fifth, maintenance and wear part consumption costs are substantial. Choosing durable equipment with readily available, cost-effective spares reduces downtime. It also lowers overall expenses. Finally, environmental compliance and sustainable development in mining are increasingly important. Investing in eco-friendly equipment avoids future penalties. It also enhances brand reputation. These factors, when balanced, ensure a high ROI for feldspar processing equipment.

Long-term stability and future readiness are vital. They ensure continuous, profitable operation of feldspar processing equipment. Effective maintenance practices minimize downtime. They also extend equipment lifespan. Strategic upgrades enable adaptation. They help meet evolving market demands. They also incorporate new technologies. This proactive approach sustains competitiveness.

A robust maintenance program is the cornerstone. It ensures equipment stability. This includes routine inspections, lubrication, and prompt repair of wear parts. For feldspar processing, special attention to crusher liners, grinding media, and classifier components is crucial. Using high-quality, specialized wear parts (e.g., ceramic liners for ball mills) significantly reduces operational costs. It also minimizes iron contamination. Predictive maintenance using sensors and data analytics can anticipate failures. This prevents costly unscheduled downtime. Beyond maintenance, strategic upgrades keep a plant competitive. This could involve replacing older crushers with more energy-efficient cone crushers or VSI crushers. It might mean upgrading classifiers for finer products. Integrating automation systems improves control. It also enhances efficiency. Adopting new beneficiation technologies, like advanced flotation cells, can improve purity. These upgrades reduce operating costs. They also allow for production of higher-value feldspar products. This ensures the facility remains productive and adaptable. It meets future market needs.

The non-metallic mineral processing industry is continuously evolving. Feldspar processing sees ongoing innovation. These developments focus on efficiency, purity, and sustainability. New technologies promise to further enhance production capabilities. They also reduce environmental impact.

Question 1: What is the optimal fineness for feldspar used in glass manufacturing?

For glass manufacturing, feldspar typically requires a fineness of 20-200 mesh. This ensures proper melting properties. Precise product particle shape optimization helps avoid defects.

Question 2: How do I prevent iron contamination in my feldspar crushing process?

Prevent iron contamination by using high-chrome cast iron or specialized alloy wear parts. Implement multi-stage magnetic separators. This removes iron particles at different processing stages.

Question 3: Can a single type of grinding mill handle all feldspar fineness requirements?

No, a single grinding mill usually cannot meet all fineness requirements. Ball mills offer versatility. However, ultra-fine applications often benefit from vertical roller mills. These mills are more efficient for specific fineness.

Question 4: What are the key benefits of using a closed-circuit grinding system for feldspar?

A closed-circuit grinding system prevents over-grinding. It saves energy. It also ensures consistent product particle shape optimization. This system returns coarser particles for regrinding. It only discharges adequately sized material.

Question 5: What should be considered when choosing between dry and wet feldspar beneficiation?

The choice between dry and wet beneficiation depends on ore characteristics. It also depends on the required purity. Wet beneficiation, like flotation, achieves higher purity. This is especially true for complex ores. Dry methods are simpler. They are suitable for ores with easily removable impurities.

Effective feldspar crushing and feldspar grinding are crucial. They unlock high-value feldspar products. This process starts with meticulous impurity control. Iron contamination is a primary concern. It requires specialized equipment materials. It also needs multi-stage magnetic separation. Multi-stage crushing, using jaw crushers and cone crushers, prepares material. Efficient feldspar grinding, often with ball mills or vertical roller mills, achieves desired fineness. High-precision classifiers and wet beneficiation further enhance purity.

Integrating feldspar processing equipment into a smart production line boosts efficiency. It ensures consistent quality. Strategic equipment selection maximizes ROI. It considers material properties, product specifications, and operational costs. Proactive maintenance and targeted upgrades ensure long-term stability. They adapt to future demands.

ZONEDING MACHINE is a leading Chinese mineral processing equipment manufacturer. It specializes in B2B solutions. ZONEDING has provided reliable equipment since 2004. The factory covers 8,000 square meters. It produces over 500 units annually. The product range is comprehensive. It covers crushing, grinding, beneficiation, screening, and drying. ZONEDING offers full-service support. This includes design, manufacturing, installation, training, and after-sales service. Products export to over 120 countries. ZONEDING commits to delivering high-quality, customized, and efficient solutions. These help operations achieve their goals.

Contact ZONEDING today to optimize feldspar processing solutions.

Explore the complete process of converting spodumene ore into high-grade lithium concentrate. Covers all vital steps, from crushing to final beneficiation.

View detailsDiscover the main types of antimony ore, like stibnite, and learn the key ore dressing methods used for extraction, including flotation and gravity separation.

View detailsThe selection between Direct Flotation and Reverse Flotation constitutes a fundamental engineering decision in the design of mineral processing circuits. This choice is not merely based on mineral hydrophobicity but involves a complex analysis of...

View detailsThis guide details the dolomite processing steps: from extraction and crushing to calcination. Learn the methods that unlock its value in various industries.

View details