Gold Extraction from Oxidized Ore: Analysis of 4 Mainstream Processes

3648Compare the top 4 gold extraction processes for oxidized ore. We analyze CIL/CIP, heap leaching, flotation & more on cost, efficiency, and application.

View detailsSearch the whole station Crushing Equipment

The selection between Direct Flotation and Reverse Flotation constitutes a fundamental engineering decision in the design of mineral processing circuits. This choice is not merely based on mineral hydrophobicity but involves a complex analysis of mass balance, feed grade, reagent costs, and the specific mineralogical composition of the ore. Correctly identifying the appropriate method determines the operational efficiency, the achievable concentrate grade, and the overall economic viability of the beneficiation plant. This article provides a detailed technical comparison of these two methodologies, analyzing their application in sulfide, oxide, and silicate mineral separation.

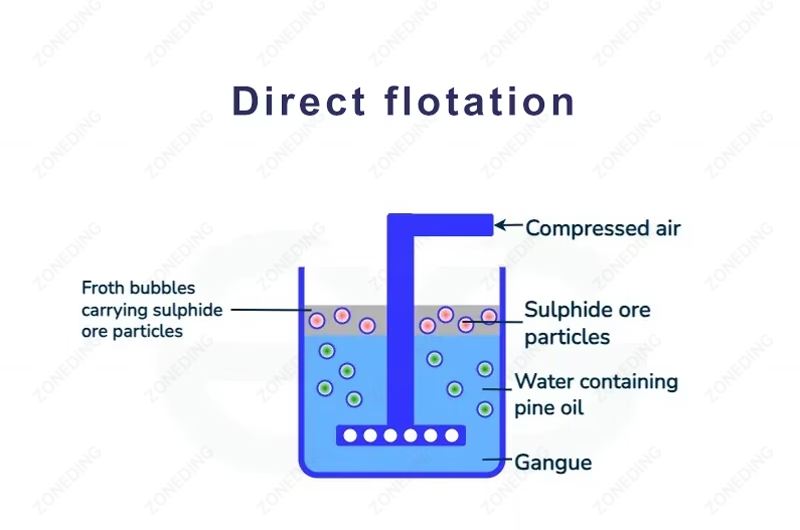

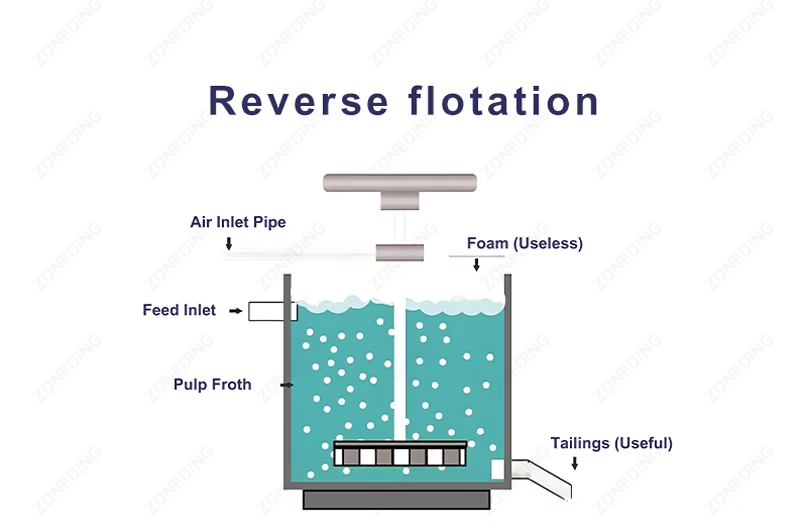

The distinction between direct and reverse flotation lies in the target of the hydrophobicity modification. The physical configuration of the flotation machine remains largely the same; the difference is entirely chemical and operational.

In direct flotation, the valuable mineral is rendered hydrophobic through the use of specific collectors. Air bubbles introduced into the pulp attach to the valuable mineral particles, lifting them to the surface to form a mineralized froth. The froth is collected as the concentrate, while the gangue minerals (waste) remain hydrophilic and sink to the bottom of the cell to be discharged as tailings. This is the standard method for most sulfide minerals.

Reverse flotation operates on the inverse logic. The gangue minerals (typically silicates or calcite) are rendered hydrophobic and floated to the surface. The froth layer contains the waste material, while the valuable mineral remains hydrophilic and is discharged from the bottom of the cell. In this scenario, the “underflow” constitutes the final concentrate. This method is frequently employed when the valuable mineral is difficult to float or when high-purity concentrates are required by removing specific impurities.

| Feature | Direct Flotation | Reverse Flotation |

|---|---|---|

| Froth Product | Valuable Concentrate | Tailings (Gangue) |

| Underflow Product | Tailings (Gangue) | Valuable Concentrate |

| Target Hydrophobicity | Valuable Mineral | Gangue Mineral |

| Typical Application | Sulfides (Cu, Pb, Zn) | Oxides (Fe), Phosphates |

The “Mass Balance” principle is the primary determinant in choosing between the two methods. The efficiency of a flotation cell is limited by its froth carrying capacity—the maximum amount of solid material that can be physically transported over the cell lip per minute.

For ores where the valuable mineral constitutes a small fraction of the total mass (e.g., Copper, Gold, Molybdenum with grades <1% to 5%), direct flotation is the standard choice. Attempting to float 95% of the gangue (waste) to recover 5% of the valuable mineral is mechanically inefficient and requires excessively large flotation circuits. Direct flotation minimizes the mass transfer to the froth phase, allowing for smaller equipment sizing and lower energy consumption.

For ores where the valuable mineral constitutes a significant portion of the feed (e.g., Iron ore at 40-50% or Phosphate), reverse flotation often proves more efficient. If the target is to upgrade a 45% iron feed to a 65% concentrate, removing the lesser volume of silica gangue via the froth is mechanically superior. Floating the heavy, abundant iron minerals would require massive froth surface areas and lead to significant entrapment of gangue due to the high solids flux.

The selection of flotation direction fundamentally shifts the trade-off curve between concentrate quality (grade) and total metal recovery.

Direct flotation typically excels in maximizing recovery. Operators can increase collector dosage to ensure all valuable particles are captured. While this aggressive approach may float some gangue via entrainment (lowering grade), it ensures minimal loss of valuable metal to tailings. It is generally easier to recover a scarce mineral directly than to ensure it does not accidentally float during a reverse process.

Reverse flotation is often the superior method for achieving high-purity concentrates. By floating the gangue, the process allows for the selective removal of specific impurities (such as silica or alumina) that are detrimental to downstream smelting or chemical processing. The valuable mineral remains in the pulp phase, unaffected by the mechanical instability of the froth. This is why Iron Ore Beneficiation relies heavily on reverse flotation to reduce silica content below 4%.

The chemical regimes required for these two processes differ significantly, directly impacting the Operating Expenditures (OpEx).

Direct flotation of sulfides typically utilizes thiol-based collectors such as Xanthates or Dithiophosphates. These reagents are:

Reverse flotation, particularly for silicate removal, often employs cationic collectors (Amines) or anionic collectors (Fatty Acids).

Particle size distribution, specifically the presence of ultra-fine particles (slimes), affects direct and reverse flotation differently.

In direct flotation, slimes can coat larger valuable particles (“slime coating”), preventing collector adsorption and reducing recovery. While problematic, this issue is often manageable through dispersants and stage-grinding.

The presence of slimes is detrimental to cationic reverse flotation. Clay minerals and slimes possess high specific surface areas and often carry negative surface charges. Cationic collectors (Amines) indiscriminately adsorb onto these huge surface areas rather than the target silica particles.

The operational philosophy and visual management of the plant differ between the two methods.

Tailings management strategies must account for residual reagents. Direct flotation tailings contain xanthates which degrade relatively quickly. Reverse flotation froths (which become tailings) contain amines or fatty acids. These surfactants are persistent and can cause foaming issues in tailings dams and water recycling circuits. Water treatment plants must be designed to handle these specific chemical loads.

Different mineral industries have standardized on specific methods based on the logic of mass balance and mineralogy.

The global standard for hematite and magnetite concentration involves magnetic separation followed by Reverse Cationic Flotation.

Copper Processing almost exclusively utilizes Direct Flotation.

Phosphate beneficiation often employs a “Double Flotation” strategy to handle complex gangue.

| Parameter | Direct Flotation | Reverse Flotation |

|---|---|---|

| Collector Charge | Negative (Anionic) | Positive (Cationic) or Anionic |

| Sensitivity to Slimes | Moderate | High (Requires Desliming) |

| Sensitivity to Water Hardness | Low | High (esp. with Fatty Acids) |

| Reagent Cost | Generally Lower | Generally Higher |

| Tailings Handling | Standard | Potential Foaming Issues |

The decision between Direct and Reverse Flotation is strictly dictated by the ore characteristics and economic targets.

ZONEDING Machine is a professional manufacturer of Beneficiation Equipment in China. We provide comprehensive solutions for both direct and reverse flotation circuits, including advanced mechanical flotation cells, agitation tanks, and reagent conditioning systems. Our technical team supports global mining operations in optimizing process flowsheets for maximum efficiency and profitability.

Contact ZONEDING for professional mineral processing solutions.

Compare the top 4 gold extraction processes for oxidized ore. We analyze CIL/CIP, heap leaching, flotation & more on cost, efficiency, and application.

View detailsSelecting the correct manganese beneficiation method is the most critical decision in plant design. The choice between Gravity Separation and Magnetic Separation is determined strictly by the ore's mineralogy, specifically density and magnetic pr...

View detailsThe Antimony Industrial Proces.Learn about modern mining methods, flotation processing, and the advanced smelting techniques used for metal extraction.

View detailsMaximize your gold recovery from ore. This technical guide explores how ball mills and wet pan mills work and which is best for efficient gold liberation.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy