How to Choose Optimal Barite Processing Equipment?

3775How to select the best barite processing equipment for operations? Learn about crushing, grinding, and beneficiation technologies to optimize efficiency yield.

View detailsSearch the whole station Crushing Equipment

Circulating Load (CL) represents a critical performance metric in mineral processing. It is not merely an indicator of grinding efficiency but a primary control variable for system throughput. In a Closed-circuit Grinding System, the circulating load is the ratio of the mass of coarse material returned to the mill to the mass of new feed entering the circuit.

Optimization of this ratio offers a direct path to lowering energy consumption per ton. While standard engineering texts often cite 250% as a baseline, operational realities frequently require adjustments based on pump curves and classification efficiency. This technical guide outlines the calculation methods, adjustment strategies for Hydrocyclones, and operational protocols to prevent over-grinding and maximize Ball Mill Efficiency Improvement.

In a closed-circuit operation, the material passes through the mill rapidly. The short residence time means the mill does not finish grinding in a single pass. Instead, the mill functions to break down particles just enough to pass the classifier.

A high circulating load increases the flow velocity within the mill. This flushing action removes fine particles (finished product) quickly. Rapid removal prevents “cushioning,” where fine particles absorb the impact energy of the steel balls meant for coarse rocks. Consequently, the grinding media expends energy on coarse particles, increasing Ball Mill Efficiency Improvement.

Conversely, a low circulating load indicates material stays in the mill too long. This leads to over-grinding, producing excessive slimes (particles <10 microns). Slimes are difficult to recover in Flotation and impede filtration in downstream processes.

The only accurate method to determine circulating load is through particle size analysis (Screen Test). Flowmeters are often inaccurate due to air entrainment in the slurry. The calculation uses the percentage of material passing a specific mesh size (typically the circuit target size, e.g., 200 mesh or 74 microns).

CL(%)=u−dd−o×100

Where:

CL=15−4545−90×100=−30−45×100=150%

In this scenario, a 150% circulating load is generally considered low for a ball mill, suggesting potential capacity for increased feed or a need to adjust the classifier to return more material.

Several physical factors dictate the natural circulating load of a circuit. Understanding these helps in setting realistic targets.

Harder ores (high Bond Work Index) naturally generate higher circulating loads. The mill breaks fewer particles per pass, resulting in more coarse material reporting to the underflow. Soft ores grind quickly, often resulting in lower circulating loads. Operators must increase the feed rate for soft ores to maintain an efficient bed of material in the mill.

Coarser feed (F80) requires more impact energy. If the Crushing Plant delivers oversized rock, the mill simply cannot break it fast enough. This builds up in the circuit, spiking the circulating load until the mill chokes. Stable operation requires a consistent feed size.

The efficiency of the Hydrocyclone or Spiral Classifier is the gatekeeper. Ideally, the underflow should contain zero finished fines. In reality, water carries fines into the underflow (Bypass). If the classifier is inefficient, the calculated circulating load may appear high, but it is a “False Load” composed of fines rather than coarse particles requiring grinding.

The grinding media must match the circulating load. A high circulating load implies a high volume of coarse particles. This requires a ball charge with sufficient impact force (larger balls) and sufficient surface area. Worn media reduces the breakage rate, causing the load to accumulate uncontrollably.

To manipulate the circulating load towards the optimal range (typically 250%-350%), specific mechanical and operational adjustments are necessary.

The cyclone determines the cut point and the split of mass.

The slurry pump feeding the cyclone provides the energy for separation.

Water addition is the fastest operational control.

A grinding circuit has a maximum transport capacity. Exceeding this leads to “Belly Full.”

Advanced circuits now employ real-time particle size analyzers (PSI) coupled with AI control systems.

Q1: What is the ideal circulating load percentage for a ball mill?

While 250% is a standard textbook figure, modern high-efficiency circuits often target 300% to 400%. The ideal number is the point where the mill consumes maximum power (drawing peak amps) while producing the target grind size without overloading the pump or cyclone.

Q2: How does circulating load affect the specific energy consumption (kWh/t)?

Optimized high circulating load generally reduces specific energy consumption. By removing fines rapidly, the mill energy is focused on coarse particles, preventing energy waste on over-grinding. Although pump energy increases, the gain in mill grinding efficiency outweighs the pumping cost.

Q3: Why is my calculated circulating load extremely high (over 600%)?

A result over 600% usually indicates a “short circuit” or measurement error. It implies the classifier is sending almost everything back to the mill. Causes include a clogged cyclone overflow, an extremely large apex, or very low feed pressure preventing separation.

Q4: Can I increase circulating load without changing the pump?

Usually, no. Increasing the load means moving more volume. If the pump is already running at 50Hz/60Hz, it cannot move the extra mass. Optimizing for higher loads typically requires upsizing the pump and the cyclone feed lines.

Q5: What is the difference between “True” and “False” circulating load?

True circulating load consists of coarse particles that need regrinding. False circulating load consists of fine particles (already finished) that are carried back to the mill due to inefficient classification (bypass). Reducing False load improves circuit capacity.

Q6: How does ore variability impact the circulating load setting?

If the ore becomes harder, the circulating load will naturally rise as the mill breaks less material per minute. The operator must either reduce the new feed rate or increase the grinding media charge to compensate and prevent overload.

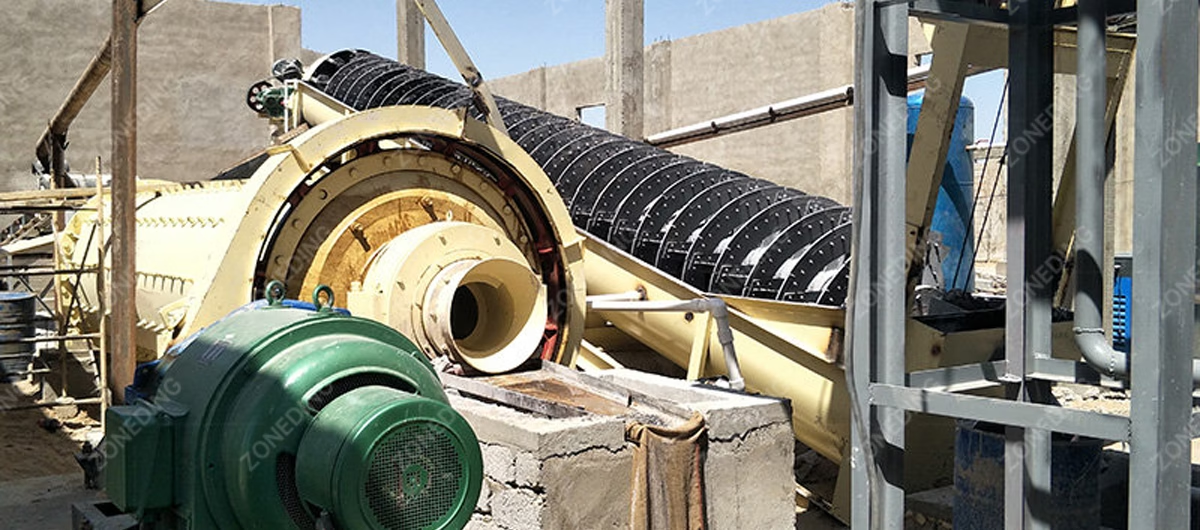

ZONEDING Machine is a premier manufacturer of mineral processing equipment. We provide complete comminution solutions, including Ball Mills, Rod Mills, and advanced classification systems. Our technical team assists mines globally in optimizing circuit designs to handle high circulating loads for improved recovery rates.

Contact ZONEDING today for a circuit audit and efficiency analysis.

How to select the best barite processing equipment for operations? Learn about crushing, grinding, and beneficiation technologies to optimize efficiency yield.

View detailsChoosing your fluorite processing equipment? Discover critical factors like ore characteristics, capacity needs, and cost-efficiency to select the best machine.

View detailsLearn the step-by-step process for gold extraction from oxidized ore. We define this mine type and list the key equipment for each stage of the operation.

View detailsFeldspar is a critical mineral. It serves as a fundamental raw material. It is vital for ceramics, glass, and filler industries. High-quality Feldspar is essential. This equipment helps transform raw ore into high-value products. This guide provi...

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy