Jig Gravity Separation: Process Analysis & Critical Factors

3872A dynamic fluidized bed is key. Water pulses separate particles; heavier sink, lighter rise. Precise control ensures efficient Jig separation.

View detailsSearch the whole station Crushing Equipment

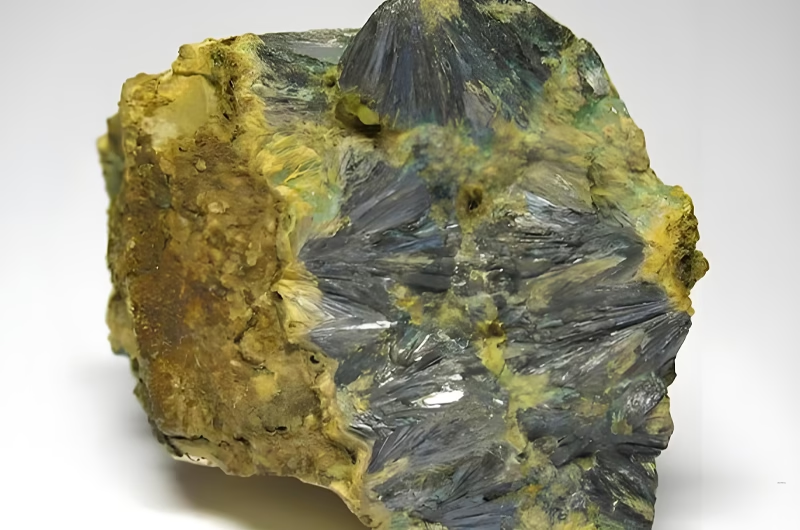

Selecting the correct antimony ore beneficiation process is a critical decision that depends entirely on the ore’s mineralogy. Antimony is a specialized metal, and its processing requires a different approach than more common commodities like iron or copper. The physical and chemical properties of the antimony ore types dictate the entire flowsheet, the choice of antimony processing equipment, and the financial viability of the project. A process that works perfectly for one type of ore will fail completely on another. This guide explains how to make the right choice for your specific deposit.

The first step in any antimony ore processing project is to identify the mineral composition. This classification determines the entire technical route. Antimony ores are divided into three main industrial types based on their mineral content.

For a single antimony sulfide ore, where stibnite is the target mineral, the processing method depends on how the stibnite is distributed in the rock. Stibnite is very soft and brittle, which makes it prone to creating ultra-fine particles (“slimes”) during grinding. Slimes are difficult to recover. Therefore, the best process for stibnite beneficiation minimizes over-grinding.

A highly effective and common method is the gravity-flotation combined process. This approach uses the strengths of both techniques.

Processing sulfide-oxide mixed antimony ore is more challenging because flotation will not recover the oxide minerals. The most common solution is a variation of the combined process:

For refractory antimony oxide ore, froth flotation is not an option. The main method is gravity separation if the minerals are coarse enough. If the ore grade is sufficiently high, it is often mined and sold directly to a specialized smelter without any on-site concentration.

Antimony ores frequently contain other valuable metals like gold, tungsten, or mercury. A successful antimony ore beneficiation process for these complex ores must include steps for the comprehensive recovery of multiple metals.

For a gold-bearing antimony ore, the process is carefully designed for antimony-gold separation technology. Often, a gravity-flotation process is used first to create a mixed antimony-gold concentrate. This mixed concentrate is then treated further. A common method is to use leaching to dissolve the gold, leaving the antimony minerals behind as a solid for separate processing. In other cases, selective flotation can produce a separate gold concentrate and an antimony concentrate. The exact method depends on the specific minerals and their associations, which must be determined by testing.

A mineral processing test procedure is not optional; it is the most critical step in designing a profitable antimony production line. An ore that looks simple can have complex mineral intergrowths or problematic impurities that are only revealed through detailed lab work. You cannot select an antimony process selection from a textbook.

The testing process provides essential data:

Investing in a proper test report from a qualified lab is the best way to minimize risk and ensure your plant is designed correctly from the start.

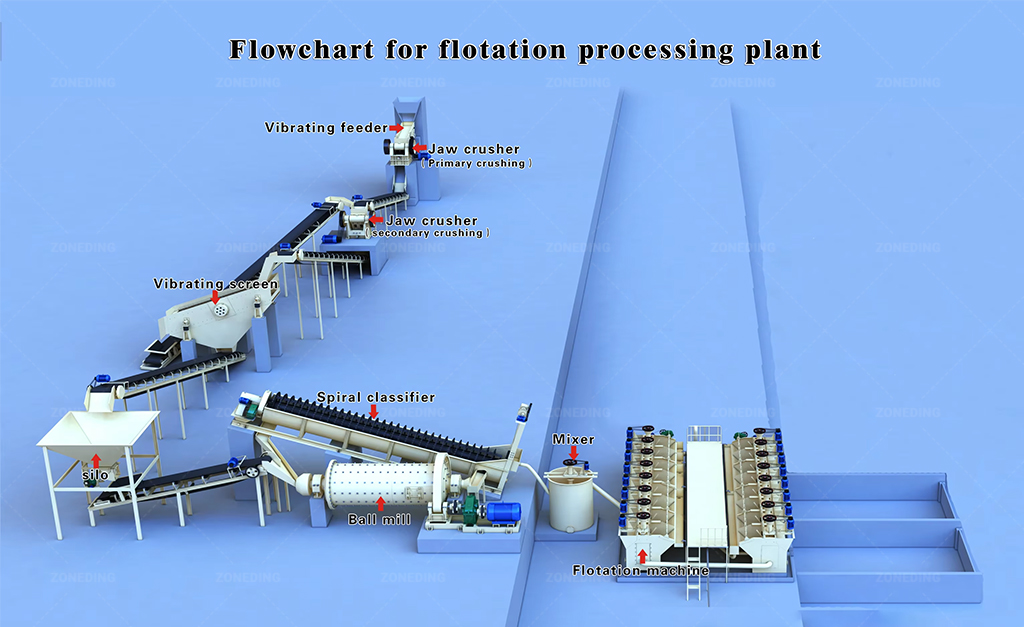

| Stage | Key Equipment | Purpose | Your Benefit |

|---|---|---|---|

| Crushing | Jaw Crusher, Cone Crusher | Reduce large run-of-mine ore into smaller, manageable sizes for grinding. | Prepares material for efficient liberation. |

| Grinding | Ball Mill, Spiral Classifier | Grind the ore to the target liberation size in a water-based slurry. | Frees valuable minerals from waste rock. |

| Gravity Separation | Jig Separator, Shaking Table | Recover coarse, heavy stibnite particles using density differences. | Low-cost, early recovery of high-grade antimony. |

| Flotation | Flotation Machine, Agitator Tanks | Selectively float fine stibnite particles away from waste rock. | Recovers fine antimony that gravity would lose. |

| Dewatering | Thickener, Filter Press | Remove water from the final antimony concentrate to prepare for shipping. | Produces a saleable product with low moisture. |

Question 1: What is the biggest challenge in stibnite beneficiation?

The biggest challenge in stibnite beneficiation is managing its brittle nature. Stibnite easily over-grinds into ultra-fine particles, or ‘slimes.’ These slimes are difficult to recover with both gravity and flotation methods, leading to significant antimony losses.

Question 2: Why is a gravity-flotation combined process common for antimony?

A gravity-flotation combined process is common because it leverages the strengths of both methods. Gravity separation efficiently recovers coarse stibnite at a low cost. The finer particles are then treated by flotation, which is more effective for fine material. This dual approach maximizes the overall antimony recovery rate.

Question 3: How do you separate arsenic from antimony concentrate?

Separating arsenic from antimony concentrate is a key challenge in flotation. It is achieved chemically by using specific ‘depressant’ reagents and carefully controlling the pH of the slurry. This prevents the arsenic minerals from floating while allowing the stibnite to be recovered.

Question 4: Can you process antimony oxide ore with flotation?

No, standard froth flotation is ineffective for antimony oxide ores. The chemical collectors used in flotation are designed for sulfide minerals. Oxide minerals have a different surface chemistry and require different methods, such as gravity separation or direct pyrometallurgical enrichment.

Choosing the right antimony ore beneficiation process is a matter of precise technical evaluation, not guesswork. The correct path is always determined by the ore itself.

Since 2004, ZONEDING has been a manufacturer of beneficiation equipment. We have extensive experience in designing and supplying complete solutions for complex ores like antimony. We understand the unique challenges of stibnite beneficiation and the importance of a customized flowsheet. Our engineers can guide you through the process, from initial ore testing to the configuration of a full production line with the right crushers, mills, and flotation cells for your specific needs.

Contact us to discuss your antimony project. We are ready to help you build an efficient and profitable processing plant based on sound engineering and a deep understanding of mineralogy.

A dynamic fluidized bed is key. Water pulses separate particles; heavier sink, lighter rise. Precise control ensures efficient Jig separation.

View detailsDiscover all about rock crushing machines: types, applications, working principles, & how to choose the best one for your project. Get expert insights here!

View detailsUnlock the economic and environmental benefits of tailings recycling. Discover how this sustainable solution transforms mining waste into valuable materials.

View detailsThe perfect solution for gold mining. Our portable hard rock crushers are engineered to process gold-bearing ore efficiently.

View details