How to Process Lead-Zinc Ore: The Galena Beneficiation Line

3665A detailed explanation of a lead-zinc ore processing line. Understand the science of preferential flotation to separate lead (galena) and zinc concentrates.

View detailsSearch the whole station Crushing Equipment

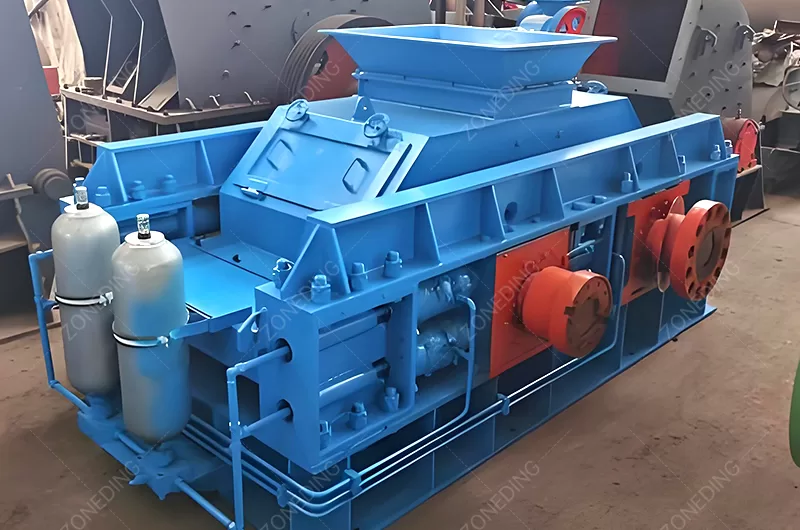

Safe operation of the hydraulic roll crusher ensures a long machine life. The hydraulic system provides the necessary pressure for effective crushing. This guide covers essential operating procedures and maintenance steps. Following these rules prevents accidents and reduces downtime. It is important to monitor pressure and wear regularly. This information helps operators achieve the best performance in 2026.

Mechanical and hydraulic checks are the first step every day. Personnel must inspect all bolts on the machine frame. Loose bolts cause vibration and damage the structure. The oil level in the hydraulic tank must be within the safe range. Low oil leads to air in the system. This causes the cylinders to move unevenly. Check the hydraulic hoses for any leaks or cracks. High-pressure oil leaks are dangerous for the staff.

The roll surface must be clear of any debris or tools. Inspect the lubrication points for the bearings. Every bearing needs the right amount of grease to stay cool. Check the tension of the drive belts or the condition of the coupling. Any sign of wear means the part needs a replacement. These simple steps prevent major breakdowns later in the day. Proper inspection is part of standard .

| Check Point | Standard Condition | Benefit |

|---|---|---|

| Hydraulic Oil Level | Between Min and Max | Prevents pump cavitation |

| Bolt Tightness | No movement | Reduces structural vibration |

| Roll Surface | Clean and empty | Prevents motor overload |

The start-up sequence follows a strict logic to protect the equipment. The hydraulic station must start first. This allows the system to build the working pressure. This pressure holds the rolls in the correct position. The operator should wait for the pressure to reach the set point on the gauge. This usually takes between 30 and 60 seconds. Then, the main motor can start.

Starting the motor while the hydraulic pressure is low is incorrect. It causes the rolls to move during the first impact. This movement damages the hydraulic cylinders and the bearing seats. The interval between the pump and the motor ensures the lubrication oil is also flowing. Many modern systems use an interlock to prevent the motor from starting too early. Following this order protects the electrical system from high current surges.

| Step Number | Component | Action | Reason |

|---|---|---|---|

| 1 | Hydraulic Pump | Start | Builds holding pressure |

| 2 | Delay Timer | Wait 60s | Stabilizes oil flow |

| 3 | Main Motor | Start | Begins roll rotation |

Starting a roll crusher with material inside is a mistake. This is called a loaded start. It puts a massive load on the main motor. The motor might stall or blow a fuse. It also strains the drive belts and the gearbox. The rolls need to reach their full operating speed before they touch any stone. This speed provides the kinetic energy needed for efficient crushing.

If material stays in the chamber from the last shift, it can get damp. Damp material sticks to the rolls and creates a blockage. The hydraulic system might try to push the rolls back to clear the blockage. This creates high-pressure spikes in the oil lines. These spikes can burst seals or damage the pump. Always ensure the chamber is empty before hitting the start button. This rule saves the motor and the power system.

The hydraulic station works within a specific pressure range to keep the rolls together. Most machines operate between 5 MPa and 10 MPa. If the pressure is too low, the rolls will push apart. This makes the final product size too large and irregular. If the pressure is too high, the machine frame experiences unnecessary stress. The operator must adjust the pressure based on the hardness of the ore. Harder ore requires higher pressure for effective crushing.

Oil temperature is a critical factor for the health of the pump and valves. The normal operating temperature is 30 to 50 degrees Celsius. An alarm will sound if the oil reaches 60 degrees. High temperatures make the hydraulic oil too thin. Thin oil does not lubricate the internal parts of the pump. It also causes the rubber seals to become brittle and leak. The cooling system must start if the temperature rises above the limit. Keeping the oil cool extends the life of the entire hydraulic circuit.

The life of the roll shell depends on how the material enters the machine. The feeder must distribute the ore across the entire width of the rolls. If the ore falls only in the center, the center will wear down fast. This creates a “saddle” shape on the roll surface. A saddle shape makes it impossible to produce fine sand. The gaps at the edges stay large while the center is narrow. Proper feeding ensures the roll surface stays flat for a long time.

Operators should use a distribution plate or a wide vibrating feeder. The feed speed must remain constant to prevent pressure spikes. Sudden dumps of material cause the hydraulic system to react violently. This leads to fatigue in the machine frame. Staff must check the feed pattern every hour. If the feed is hitting one side, the feeder must be adjusted immediately. Even wear reduces the need for expensive roll grinding or replacement.

| Feed Pattern | Resulting Wear | Product Quality |

|---|---|---|

| Center Focused | Saddle Shape | Poor (too many coarse bits) |

| Left or Right Side | Tapered Wear | Bad (unstable operation) |

| Full Width | Even Wear | Excellent (consistent size) |

Metal objects like drill bits or shovel teeth are “tramp iron.” These objects are too hard to be crushed. When metal enters the rolls, the hydraulic pressure spikes instantly. The relief valve must open to let the oil flow back to the tank. This allows the moving roll to retreat and let the metal pass through. Without this feature, the metal would break the rolls or the main shaft.

The nitrogen accumulator plays a key role here. It acts as a storage for energy during the impact. If the nitrogen pressure is wrong, the roll will not retreat fast enough. This causes a massive mechanical shock. Repeated impacts with metal will crack the roll shells. Staff should use a magnetic separator before the crusher to catch these items. Keeping metal out of the chamber is the best way to protect the hydraulic system.

Bearings handle the full load of the crushing process. Their temperature must stay below 75 degrees Celsius during operation. Staff should use an infrared thermometer to check the bearing housings every two hours. A sudden rise in temperature means the bearing is failing or needs grease. If the temperature hits 80 degrees, the operator must stop the machine. Overheating will melt the bearing cage and lock the shaft.

Vibration is a sign of imbalance or loose parts. The machine should run with a steady sound and very little shaking. If the vibration frequency changes, a rock might be stuck on the roll. Or, the roll shells might be loose. Some machines have vibration sensors that stop the motor automatically. High vibration damages the foundation and the electrical connections. Regular monitoring catches these problems before the machine breaks down.

The gap between the rolls determines the size of the finished stone. Adjusting this gap is a common task. This must happen while the feeder is off and the machine is empty. The hydraulic system moves the floating roll to the desired position. Staff then lock the position using shims or hydraulic locks. The gap must be equal on both the left and right sides of the rolls.

An uneven gap causes the machine to vibrate. It also makes the product size inconsistent. Use a feeler gauge to measure the gap accurately. If the gap is 5mm on one side, it must be 5mm on the other side. Safety is very important during this adjustment. No one should put their hands near the rolls while the hydraulic pump is running. Proper gap control ensures the product meets the project requirements.

An emergency stop is for immediate danger to the machine or staff. If a hydraulic hose bursts, the oil will spray out under high pressure. The operator must hit the red emergency button immediately. This button stops the pump and the motor at once. The same step is necessary if the motor begins to smoke or makes a loud grinding noise. An electrical overload also requires an immediate stop to prevent a fire.

After an emergency stop, the machine is still under pressure. Do not touch any hydraulic lines until the pressure is released. Find the source of the leak or the cause of the overload. If the chamber is full of stone, it must be cleared by hand. The system must be inspected by a technician before the next start. Following the Crusher emergency stop procedure prevents small accidents from becoming disasters.

Stopping the machine requires a specific order. First, turn off the feeding equipment. The rolls must continue to turn until all the material is gone. An empty chamber ensures the next start is easy and safe. Then, stop the main motors. The rolls will take some time to stop spinning due to their weight. Do not try to stop them by throwing rocks into the chamber.

The hydraulic station is the last part to turn off. Some operators leave the pump on for 5 minutes to let the oil circulate through the cooler. Finally, turn off the main power isolator. This prevents accidental starts. Check the machine for any new leaks or loose bolts after it stops. This is the best time to perform a quick inspection. A clean shutdown process protects the equipment for the next day.

Lock Out Tag Out (LOTO) is the most important safety rule. It ensures the machine cannot start while a person is inside or near the rolls. First, turn off the main electrical breaker. Put a padlock on the handle and take the key with you. Then, put a tag on the lock with your name and the date. This tells everyone that you are working on the machine.

The hydraulic pressure must also be released. Open the drain valves to let the oil return to the tank. A cylinder under pressure can move suddenly even with the electricity off. This “stored energy” is a major hazard. Check the pressure gauges to ensure they read zero. Use mechanical blocks to prevent the rolls from turning. This process is essential for Safety production of mineral processing equipment.

Roll shells are the main wear part of the crusher. Staff must measure the thickness of the shells every week. Use a micrometer or a template to check the surface. Record the measurements in a logbook. This record helps the management predict when the shells will need replacement. It prevents unexpected downtime during a busy production period.

Look for deep pits or cracks on the metal surface. Small pits are normal, but deep cracks are dangerous. A cracked shell can shatter and destroy the machine. Note the gap between the rolls and the cheek plates. If the gap is too large, the stone will leak out and wear the machine frame. Tracking these numbers is a key part of Roll shell wear monitoring. It ensures the machine produces high-quality material for the longest possible time.

| Wear Parameter | Record Frequency | Replacement Threshold |

|---|---|---|

| Shell Thickness | Weekly | 30% of original depth |

| Surface Flatness | Bi-weekly | 5mm deviation (Saddle) |

| Cheek Plate Gap | Daily | 3mm maximum |

Question 1: How often should the hydraulic oil be replaced?

Replace the hydraulic oil every 2000 hours of work. If the oil looks white or cloudy, change it immediately. Cloudy oil contains water which will rust the pump and valves.

Question 2: Why is the oil temperature rising above 60 degrees?

The most common cause is a dirty oil cooler or a blocked filter. It can also be a sign of a failing pump. Clean the cooling fins and check the oil level first.

Question 3: How often should the nitrogen pressure be checked?

Check the nitrogen pressure in the accumulator once a month. If the nitrogen leaks, the hydraulic system will lose its ability to handle impacts from metal.

Question 4: Can the machine crush stones larger than the feed opening?

No. Large stones will bounce on top of the rolls. This causes vibration and can damage the feeder. Always follow the maximum feed size limit in the manual.

Question 5: What causes the main motor to trip the breaker?

This usually happens due to a loaded start or an uneven feed. Check if the chamber is full of stone. Also, ensure the drive belts are not too tight.

Safe operation of the hydraulic roll crusher requires daily attention to pressure and wear. Operators must follow the correct startup and shutdown sequences. Monitor the bearing temperature and the feed distribution every hour. Use LOTO procedures for all maintenance work to protect staff. Record the roll shell thickness every week to plan for replacements. These steps ensure the machine runs efficiently in 2026. Keeping the machine clean and well-lubricated is the best way to prevent high repair costs.

ZONEDING is a professional manufacturer of mining and crushing equipment. We have produced high-quality machines since 2004. Our products are in use in over 120 countries worldwide. We offer direct factory sales and full technical support. Our engineers help customers design the best production lines for their specific needs. We focus on efficiency, safety, and long-term reliability for all our clients.

Contact us for a free technical consultation and equipment quote.

A detailed explanation of a lead-zinc ore processing line. Understand the science of preferential flotation to separate lead (galena) and zinc concentrates.

View detailsQuickly diagnose & fix common crusher & grinder issues. Our guide covers overheating, blockages, & wear with practical solutions.

View detailsTungsten is a strategic metal characterized by its extreme density and brittleness, often described in mineral processing as "heavy as iron but fragile as glass." The successful extraction of this metal depends entirely on correctly identifying t...

View detailsThe selection between Direct Flotation and Reverse Flotation constitutes a fundamental engineering decision in the design of mineral processing circuits. This choice is not merely based on mineral hydrophobicity but involves a complex analysis of...

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy