Gold Cyanidation: From Process Types to Plant Construction

3698Your ultimate guide to gold cyanidation. Explore CIL/CIP types, detailed processes, and the complete steps for successful plant construction and optimization.

View detailsSearch the whole station Crushing Equipment

Solid waste processing turns construction debris into valuable materials. Efficient production requires the right combination of machinery and sorting technology. Modern projects focus on high recovery rates and low operating costs. This guide explains how to select the best equipment for different waste types in 2026. Objective data shows that proper machinery choice reduces waste volume by 90%.

The market offers two primary categories: stationary plants and units. Stationary plants suit permanent recycling centers with high daily volumes. These installations require concrete foundations and long conveyor systems. They handle massive amounts of material over many years. Fixed plants provide the highest stability for heavy-duty crushing operations.

Mobile units offer flexibility for urban demolition sites. These machines move directly to the source of the waste. This eliminates the need for expensive trucking to a central location. The Mobile Crusher category includes wheeled and tracked versions. Most solid waste lines also feature primary crushers, secondary crushers, and various screening decks. Each component plays a specific role in the recycling process.

| Equipment Type | Best Use Case | Mobility | Key Advantage |

|---|---|---|---|

| Stationary Line | Centralized Hubs | None | Max Capacity |

| Wheeled Mobile | City Road Projects | Medium | Fast Transport |

| Crawler Mobile | Rough Demolition | High | Remote Movement |

The Jaw Crusher serves as the primary tool for large concrete blocks. These machines possess a wide feed opening to accept bulky slabs. The mechanism uses a moving jaw to squeeze material against a fixed plate. This force breaks the bond between concrete and steel rebar. Once the concrete shatters, the metal pieces become loose. This simplifies the later stages of the recycled aggregate production process.

The design of a jaw crusher handles “un-crushable” items safely. A toggle plate acts as a mechanical fuse. It breaks if a large steel object enters the chamber. This protects the expensive motor and eccentric shaft from damage. Maintenance is straightforward and requires basic tools. The simplicity of the jaw crusher makes it the industry standard for the first stage of waste reduction. It remains reliable even in dusty and harsh environments.

An Impact Crusher focuses on the shape and size of the final product. It uses high-speed blow bars to strike the material. This action creates a cubic shape in the recycled stone. Cubic aggregate is superior for making new concrete or road bases. It provides better structural strength than the flat or elongated pieces from other crushers. High-quality recycled stone attracts a higher market price.

Modern Mobile Impact Crusher models include hydraulic safety systems. These systems detect large metal pieces that could damage the rotor. The internal curtains lift automatically to let the metal pass through. This prevents broken blow bars and long periods of downtime. The impact crusher is essential for any plant aiming to produce premium construction materials from waste. It turns low-grade rubble into professional-grade aggregate.

Effective waste sorting technology is necessary for complex waste streams. A Magnetic Separator is the first line of defense against metal. This device hangs over the discharge conveyor belt. It pulls steel rebar and nails away from the stone. The metal is then dropped into a separate collection area. Recovered steel represents a significant profit source for recycling operators.

Wood, plastic, and paper require air separation. An air sifter blows a strong current of air through the falling material. Light objects like wood chips fly into a collection bin. Heavy stones fall straight down onto the next conveyor. Clean aggregate must have less than 1% light material to meet construction standards. Air separation is the most efficient dry method for removing these contaminants. This step is vital for producing high-value sand and gravel.

Tracked mobile stations provide the best movement on soft or uneven ground. These machines use heavy-duty crawlers like an excavator. The operator moves the Tracked Jaw Crusher using a remote control. This allows the machine to follow the work face at a demolition site. It reduces the distance that loaders must travel. Tracked units are the preferred choice for rough terrain and narrow city sites.

Wheeled mobile stations function like large trailers. A truck tractor pulls them between different job sites. They are ideal for projects that move frequently along roads or highways. The cost of a wheeled unit is generally lower than a tracked unit. But they require flat, firm ground to operate safely. Setup time for wheeled stations takes longer because they need hydraulic legs for stability. The choice depends on the specific site conditions and the frequency of relocation.

| Feature | Tracked Station | Wheeled Station |

|---|---|---|

| Mobility Type | Self-propelled | Towed by truck |

| Ground Terrain | Mud/Rough ground | Flat/Hard surface |

| Movement Speed | Slow (crawler) | High (highway) |

| Setup Time | 15 minutes | 2 hours |

The Vibrating Screen determines the size of the final products. Solid waste often contains wet dirt and sticky debris. Finger screens are a specialized solution for the top deck. These consist of vibrating steel bars that prevent clogging. They allow large rocks to bounce while smaller items pass through. Traditional wire mesh often blocks up when processing damp construction waste.

Secondary decks use standard mesh to create precise sizes like 10mm or 20mm. These sizes are common for road building and concrete mixing. The Vibrating Screen must be easy to access for regular cleaning. Changing the screen decks allows the plant to meet different customer requirements. A high-quality screening process ensures the final product is consistent and clean. This consistency is key to building trust with buyers.

Wear parts are the largest operating expense in waste recycling. Choosing the right material for blow bars and liners is critical. Martensitic steel provides a balance of hardness and toughness. It resists the abrasive nature of concrete and brick. It also withstands the impact of occasional small metal pieces. Using the wrong alloy leads to cracked parts and expensive repairs.

The “bypass” strategy also reduces wear. A pre-screen removes small stones and dirt before they enter the crusher. These materials are already the correct size. Sending them through the crusher only causes unnecessary wear on the liners. It also consumes extra power and limits the capacity for larger rocks. A bypass system can increase the life of wear parts by 25%. It makes the entire operation more efficient and profitable.

Light contaminants like plastic and paper lower the quality of recycled sand. Water floating systems are one option. Stones sink while light materials float away. This produces very clean aggregate. But water systems require large tanks and water treatment facilities. This adds complexity and cost to the project. It is not suitable for sites with limited water access or strict environmental rules.

Air separators are the modern alternative. These machines use high-velocity fans to blow light materials out of the stream. They operate without water and create no sludge. The Air separator for light materials is easy to maintain. It fits easily into mobile or stationary lines. This dry technology is the industry standard for urban recycling projects. It ensures the final sand meets strict purity requirements for new construction projects.

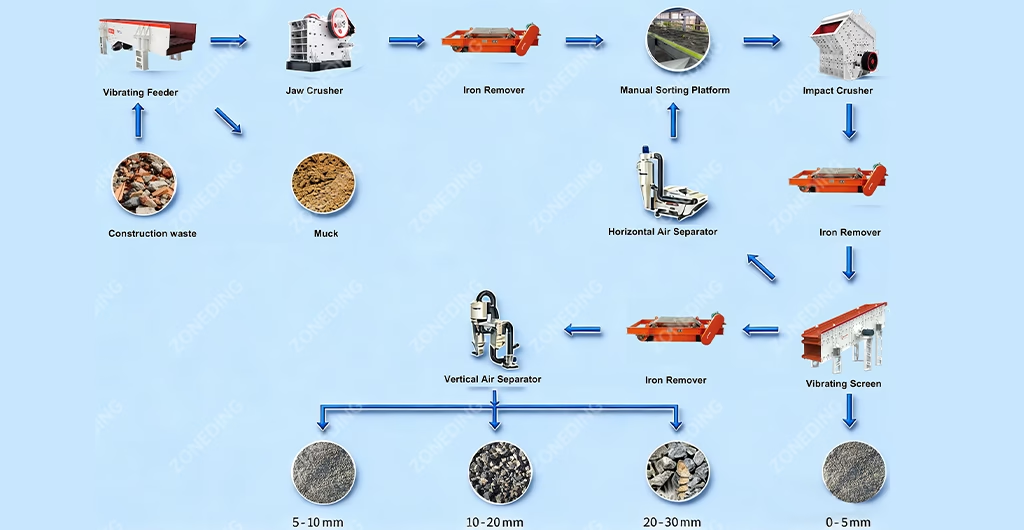

A full line starts with a heavy-duty hopper and a Vibrating Feeder. This ensures a steady flow of material into the system. The primary stage uses a Jaw Crusher to break large chunks. A magnetic belt follows to remove steel. The secondary stage uses an Impact Crusher for shaping. This combination ensures high output and good product quality.

The final stage involves a Vibrating Screen to separate products by size. Conveyor belts transport the finished sand and gravel to different piles. Some lines include a return belt for oversized rocks. These rocks go back to the crusher for further reduction. Automation systems control the entire process from a single panel. This reduces the need for manual labor and increases safety on the site.

In 2026, the industry focuses on “Zero-Waste” goals. New technology allows plants to recycle 98% of incoming debris. Even fine dust is collected and used for making eco-bricks. Electric-drive mobile plants are becoming more common. These units plug into the local power grid to save on diesel costs. They produce fewer emissions and operate more quietly in city centers.

Question 1: Is a cone crusher suitable for construction waste?

A Cone Crusher is generally avoided. Metal rebar can cause the main shaft to break. Jaw and impact crushers handle these metal risks much better.

Question 2: How is dust controlled in city projects?

High-pressure spray bars are installed on crushers and conveyors. They create a fine mist that traps dust. This method uses very little water and keeps the site clean.

Question 3: What is the benefit of a pre-screen?

The pre-screen removes dirt and small stones before the crusher. This reduces wear and increases the total capacity of the plant.

Question 4: Can mobile crushers be moved on normal roads?

Wheeled mobile crushers travel like standard trailers. Tracked units require a low-bed trailer for long-distance transport.

Question 5: How long do crusher liners last?

Liner life depends on the material. In construction waste, a set of jaw plates can last 30,000 to 50,000 tons. Regular inspection prevents damage to the machine body.

Success in waste recycling requires tough machinery and smart sorting. The Jaw Crusher handles the big blocks. The Impact Crusher creates the final shape. Magnetic and air separators ensure the product is clean. Mobile Stone Crusher units provide the best flexibility for city work. Following these guidelines will result in a profitable and efficient recycling operation.

ZONEDING MACHINE is a professional manufacturer of mining and recycling equipment. The factory has produced high-quality machinery since 2004. Products are used in over 120 countries for aggregate and ore processing. The company provides full support from design to installation. Direct factory sales ensure competitive pricing for all global B2B customers.

Contact for a professional project layout and price list.

Your ultimate guide to gold cyanidation. Explore CIL/CIP types, detailed processes, and the complete steps for successful plant construction and optimization.

View detailsHigh Pressure Grinding Rolls (HPGR) and Vertical Roller Mills (VRM) continue to gain attention in the market. However, the Ball Mill still holds over 80% of the global market share in mining. This dominance is not merely due to tradition. It stem...

View detailsIt's easy to mistake pyrite for gold. This guide shows you a simple streak test and other quick checks anyone can perform to identify fool's gold.

View detailsUnlock the economic and environmental benefits of tailings recycling. Discover how this sustainable solution transforms mining waste into valuable materials.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy