How to Select a Cone Crusher: Exploring the 4 Types

3621Making the right choice is critical. We break down the 4 main cone crusher types and guide you through key selection factors like feed size and capacity.

View detailsSearch the whole station Crushing Equipment

Alluvial gold washing often fails when sticky clay exists in the ore. This clay creates mud balls that trap gold particles and carry them into the waste piles. Breaking these mud balls requires high-energy mechanical force and specific equipment. A rotary scrubber is the best machine for this task. It turns solid clay into a liquid slurry to liberate the gold. This article explains how to design a flowsheet to maximize recovery in high-clay environments.

Clay ore creates mud balls because of high surface tension and mineral cohesion. When water meets dry, plastic clay, it forms a sticky outer layer. This layer acts like glue. As the ore rolls in a drum or on a belt, it picks up sand and small gold particles. The mud ball grows larger as it moves through the plant. These balls hide the gold inside. Gravity separation tools cannot catch gold that is inside a mud ball. So the gold stays in the ball and exits with the waste rocks.

In many sites, clay is 30% to 50% of the material. This clay is often active and swells when wet. The internal bonds of the clay are stronger than a simple water spray. Without strong mechanical rubbing, the core of the mud ball stays dry and hard. This creates a rafting effect. Gold floats away inside the ball. Mining teams must see clay as a physical barrier. Breaking this barrier is the first goal in any Gold Processing Plant.

| Clay Type | Physical Property | Impact on Recovery | Required Action |

|---|---|---|---|

| Sandy Clay | Low Stickiness | Minor Gold Loss | High Pressure Water |

| Red Laterite | High Plasticity | Major Gold Loss | Rotary Scrubber |

| Blue/Grey Clay | Extreme Cohesion | Total Gold Loss | Mechanical Agitation |

A rotary scrubber is the core equipment because it provides high attrition and long retention time. This machine is a solid steel drum on heavy rollers. The inside lets rocks hit and rub against each other. This is called autogenous grinding. The rocks act like grinding balls to smash the clay. A screen lets material out fast. But a Sand Washing Machine or scrubber keeps material inside for a long time. This makes sure every mud ball hits water and force until it turns into liquid.

The scrubber uses lifters and paddles to handle tough clay. These parts lift the ore and drop it from the top. The impact of falling rocks breaks the clay structure. For thick ore, the scrubber is the only machine that can free gold from the mud. It turns solid clay into a thin pulp. This pulp is easy to clean in the next steps of the Gold Processing Plant. Using a scrubber is the best way to handle high-viscosity gold deposits.

The main difference is that a scrubber washes while a trommel sizes. A trommel screen has holes throughout its length. Material falls through the holes very fast. The time inside a trommel is usually under 30 seconds. This is not enough time to melt thick clay. A Vibrating Screen or trommel is good for separating clean rocks. But these machines are bad at breaking hard mud balls. They do not have enough retention time.

A rotary scrubber has a long section with no holes. This is the blind section. It forces material to stay in the wash zone for minutes. Water is added to make a thick soup. Only at the end is there a small screen for sizing. This makes sure the clay is 100% broken before separation. In a Gold recovery rate test, a scrubber recovers 30% more gold than a trommel in clay mines. The scrubber is a washing machine, while the trommel is just a sifter.

Washing time depends on the plasticity index of the clay. This index shows how much water the clay holds before it flows. A high index (over 20) needs 3 to 5 minutes of washing. A low index (under 10) may only need 2 minutes. If the ore has many hard rocks, the washing time can be shorter. Rocks help the process by acting like hammers. Without rocks, the clay just slides and takes longer to dissolve.

Rotation speed must be 45% to 75% of the critical speed. Critical speed is when the material sticks to the wall because of centrifugal force. The material must cascade or fall. For very sticky clay, a slower speed is better. This lets the material tumble and rub more. For sandy ore, a faster speed is fine. Using a variable drive is the best way to control this on a Beneficiation Equipment unit.

| Plasticity Index | Ore Condition | Washing Time | Speed (% Critical) |

|---|---|---|---|

| 0 – 10 | Sandy | 1.5 Minutes | 75% |

| 10 – 20 | Medium Clay | 3.0 Minutes | 65% |

| 20+ | Heavy Clay | 5.0 Minutes | 55% |

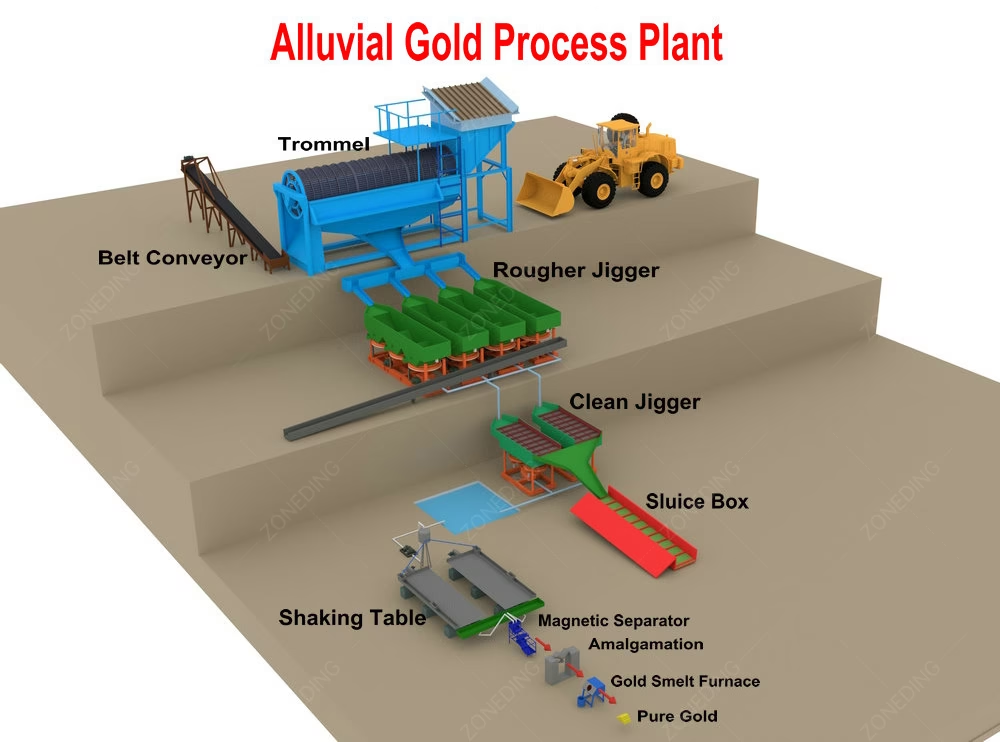

A multi-stage flowsheet uses many steps to stop gold loss. The process starts with a high-pressure water gun at the feed bin. This starts the softening. The second stage is the rotary scrubber. This is where most of the breaking happens. The third stage is a Vibrating Screen with spray bars. This removes clean stones that have no gold. It also rinses any remaining mud off the surface.

The fourth stage is de-sliming. A Hydrocyclone separates fine mud from the gold sand. If mud stays in the water, the gold machines will fail. The last stage is recovery using a Centrifugal Concentrator and a Shaking Table. This stage catches the fine gold that the scrubber liberated. This design handles mud at every point. The final gold concentrate is very clean because of these stages.

Screening equipment must use high-pressure spray bars. After the scrubber, rocks often have a thin film of mud. This film can trap tiny gold. A Vibrating Screen with two decks is the best choice. The top deck takes out big stones. The bottom deck makes the fine sand for recovery. Spray bars on both decks must hit the material hard. This strips the last mud away.

The screen mesh size is very important for recovery. If the mesh is too big, too much waste goes to the Centrifugal Concentrator. This lowers its power. If the mesh is too small, the screen will clog with clay. We use polyurethane screen panels instead of steel. Polyurethane is flexible and pops out stuck clay. This keeps the holes open. Fine gold can then move to the recovery stage without being lost.

Centrifugal concentrators use G-force to beat muddy water. In a sluice box, mud settles and fills the gold mat. When the mat is full of mud, the gold cannot sink. The gold flows away over the mud. This is called sanding over. A Centrifugal Concentrator spins very fast. This makes a force 60 times stronger than gravity. This force pushes heavy gold into the rings even if the water is thick.

The centrifuge also uses a fluidized bed. It injects clean water through small holes in the cone. This keeps the sand and mud loose. Heavy gold can get into this loose bed. Light clay is washed away. In any clay project, a centrifuge is the best tool. It gives a much higher Gold recovery rate than a sluice. It is the modern standard for recovery.

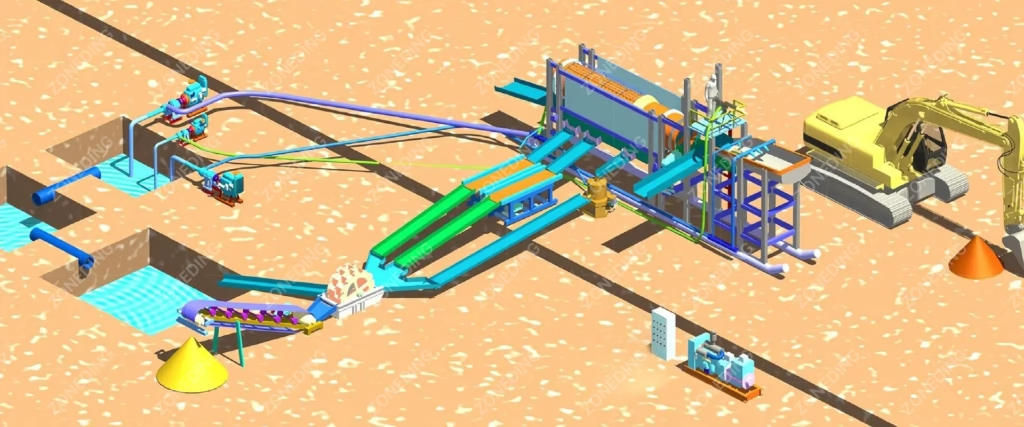

Mobile wash plants put the scrubber and screen on one trailer. For remote mines, moving equipment is a big cost. A Mobile Stone Crusher chassis can carry a whole washing plant. This includes the bin, scrubber, and centrifuge. Being mobile lets the owner move the plant as the mining face moves. This stops the need to haul sticky clay for miles.

Modular design is best for remote mines. We build the plant in parts: a washing module and a recovery module. These parts connect with bolts. This makes it easy to fix or change parts of the Gold Processing Plant. For power, these plants use diesel engines or generators. This setup is perfect for small or medium mines that need to move often.

Water monitors create a pre-slurry that helps the scrubber. A water monitor is a high-pressure nozzle. It hits the clay pile with 100 PSI or more. This cuts clay chunks into small pieces. This method makes sure the scrubber gets material that is already soft. It stops the hopper from getting blocked. This saves time and increases the total tons processed per hour.

Mechanical agitation inside the scrubber uses cutters to slice mud. Basic lifters just move the rocks. Cutters are sharp steel blades on the drum wall. They slice into mud balls as they tumble. For very bad clay, we also use Mixers in the discharge tank. This keeps clay from sticking together again before it reaches the Hydrocyclone. These two methods together break even the hardest clay.

Liner material decides the friction and machine life. We use high-manganese steel or thick rubber for scrubber liners. Steel is best for ore with big, sharp rocks. Rubber is better for fine sand and clay. Rubber liners have more grip. They pull the material higher up the wall. This makes the material fall harder. This extra friction improves the washing capacity of the machine.

Paddle design affects how long material stays inside. Spiral paddles move material to the exit. Straight paddles keep material in one spot to rub more. We use both. Straight paddles are at the start for washing. Spiral paddles are at the end for moving. If the paddles are cheap steel, they wear out fast. Using abrasion-resistant steel keeps the Beneficiation Equipment working for a long time.

High-viscosity ore needs 2 to 5 cubic meters of water per ton. This is more water than normal sand washing. Water is needed to thin the clay. If the water is too low, the slurry is too thick. Gold will not settle in thick slurry. This high water need makes a recycling system very important. Most mines cannot afford to waste this much water every day.

A recycling system uses a thickener and a filter press. Dirty water from the plant goes to a thickener tank. Chemicals are added to make mud sink. Clean water from the top is pumped back to the scrubber. This reduces the need for fresh water by 90%. This is vital for mines in dry areas. It also follows environmental rules about dirty water discharge.

| Component | Function | Efficiency |

|---|---|---|

| Thickener | Cleans dirty water | High |

| Slurry Pump | Moves thick mud | Reliable |

| Filter Press | Makes dry mud cakes | Highest |

Miners must check the rocks and the waste piles. The best test is a visual check. After the scrubber, look at the rocks. If the rocks are shiny and have no mud, the washing is good. If the rocks feel slimy or have mud in the cracks, the washing is bad. You must then increase the washing time or use more water pressure.

The second test is mud ball sampling. Take mud balls from the waste pile and break them. If there is gold inside, the plant is failing. We also use a Shaking Table in the lab to test the waste. We take 10kg of waste mud and run it on the table. If gold shows up, the Gold recovery rate needs to be fixed. Doing this every day keeps the mine profitable.

Question 1: Can a jaw crusher break clay balls?

No. A Jaw Crusher is for hard rocks. Sticky clay will clog the crusher and stop it. You must use a scrubber for clay.

Question 2: What is the best liner for a gold wash plant?

Natural rubber liners are best for alluvial gold. They handle the rubbing better and last longer than steel in wet conditions.

Question 3: How do I recover fine gold from thick slurry?

You must remove the mud first. Use a Hydrocyclone to take out the fine mud. Then send the clean sand to a centrifuge.

Question 4: How much water do I need for washing?

You need about 3 tons of water for every 1 ton of ore if the clay is thick. A recycling system can save most of this water.

Question 5: Should I use a mobile or fixed plant?

If your mine is large and stays in one place, use a fixed plant. If you move every few months, a mobile plant on a chassis is better.

ZONEDING is a manufacturer of Minerals Processing Machines with 20 years of experience. We provide full solutions for Placer Gold Mining and hard rock mines. Our products include scrubbers, Ball Mill units, and centrifuges. We design flowsheets for B2B clients in 120 countries. Our goal is to help you get more gold with less waste.

Contact ZONEDING today for a free plant design and ore test.

Making the right choice is critical. We break down the 4 main cone crusher types and guide you through key selection factors like feed size and capacity.

View detailsExplore secondary impact crushers for efficient material reduction. They produce cubical, well-shaped aggregate, ideal for construction, road building.

View detailsExplore the complete process of converting spodumene ore into high-grade lithium concentrate. Covers all vital steps, from crushing to final beneficiation.

View detailsThe perfect solution for gold mining. Our portable hard rock crushers are engineered to process gold-bearing ore efficiently.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy