How to Optimize Steel Ball Configuration for Gold Ball Mills

3873Discover critical factors in steel ball configuration impacting your gold ball mill's performance. Improve grind size, throughput, and energy efficiency today.

View detailsSearch the whole station Crushing Equipment

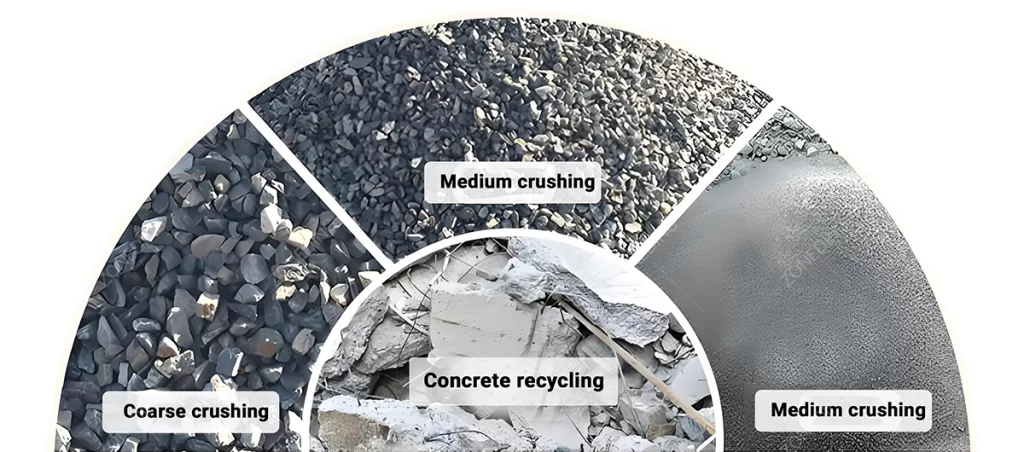

Recycling concrete is not like crushing clean rock. Choosing the wrong crushing set-up can lead to constant jams, damaged machines, and a low-quality product nobody wants. The key is selecting a system designed specifically to handle rebar and other contaminants.

Success in concrete recycling comes down to two things: how efficiently you can separate out the steel, and the quality of the final Recycled Concrete Aggregate (RCA) you produce. Your business model—whether you are a mobile contractor or a large-scale depot operator—will determine the right solution for you. Let’s break down the top three setups, from the most flexible to the most productive.

You might think the concrete itself is the hard part, but it’s not. The real enemy is the steel rebar hidden inside, ready to damage your equipment and ruin your final product.

The biggest challenge in crushing concrete with rebar is separating the ductile steel from the brittle concrete efficiently and without causing catastrophic damage to the crusher. The steel can bend, cause jams, and destroy expensive parts if the wrong machine is used.

Understanding your materials is critical. Concrete is brittle; it shatters under pressure. Steel rebar is ductile; it bends and deforms instead of breaking. The goal of a concrete crusher is to use the right force to shatter the concrete away from the steel, allowing the steel to be removed. A compression-style crusher, like a jaw, will squeeze and break the concrete while only bending the rebar. An impact-style crusher will shatter the concrete effectively but can suffer high wear from direct contact with steel. A cone crusher, which relies on a precise crushing chamber, can be catastrophically damaged by a single piece of tramp steel. Choosing the right machine is not just about crushing; it’s about surviving the contamination.

| Material | Key Property | Behavior Under Force | Best Crusher Type |

|---|---|---|---|

| Concrete | Brittle | Shatters and breaks apart | Jaw Crusher, Impact Crusher |

| Steel Rebar | Ductile | Bends and deforms, does not shatter | N/A (Must be removed, not crushed) |

You need to get on-site, crush the material, and move to the next job quickly. A single machine seems like the simplest, most flexible solution. But is it the right choice for rebar-heavy concrete?

A single mobile impact crusher offers excellent mobility and produces very well-shaped aggregate. However, for primary crushing of demolition waste with heavy rebar, a mobile jaw crusher is the more robust and reliable single-machine solution.

This choice represents a classic trade-off.

A single machine has its limits. You need higher production volume and a better-quality product to access more markets. Combining two machines seems complex and expensive, but is it worth the investment?

Yes, a two-stage mobile crushing plant, using a mobile jaw crusher followed by a mobile impact crusher, offers the perfect balance. The jaw does the heavy work of breaking and liberating steel, and the impactor creates a high-quality, specified final product.

This two-stage system is the standard for professional recycling yard operators who want to produce certified RCA. Here’s how it works:

Your business isn’t just about contracting; you’re building a major recycling depot. Mobile units seem too small for your ambitions. You need massive throughput, but the investment is significant.

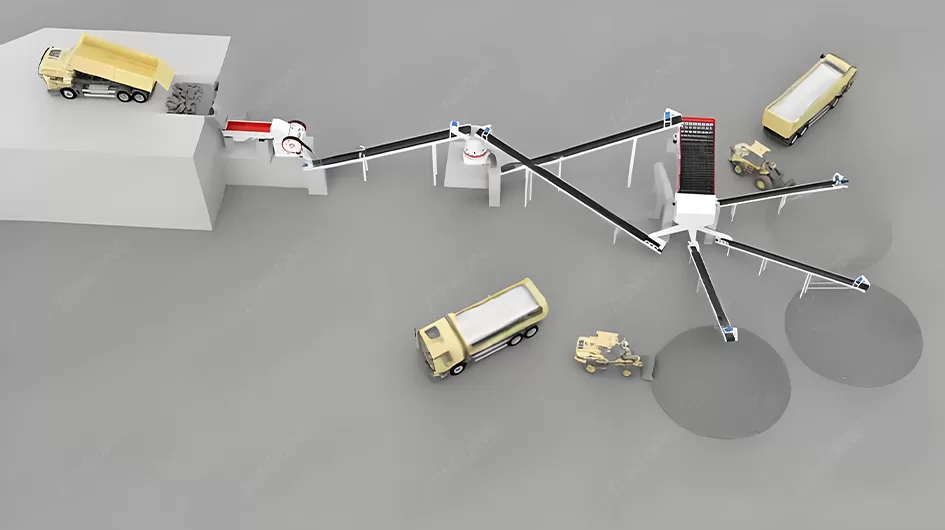

A stationary crushing plant is the ultimate solution for large-scale concrete recycling. It enables maximum efficiency, allows for advanced cleaning processes, and produces the highest quality Recycled Concrete Aggregate (RCA) that can compete with virgin materials.

This setup is for the serious, high-volume producer. A stationary line has a larger footprint and higher initial cost, but it offers unparalleled advantages. You can integrate more sophisticated equipment like:

Jaw-Impact-Screen Circuit: The core of the plant, similar to Option 2 but with larger, higher-capacity machines.

You’ve picked your crushers, but you overlook one critical component. Suddenly, your production line grinds to a halt, with a tangled mess of steel wrapped around your conveyor belt.

The magnetic separator is the non-negotiable heart of any concrete recycling system. At a minimum, a powerful, overband cross-belt magnet must be installed over the primary crusher’s discharge conveyor to remove the bulk of the rebar.

Proper configuration is essential for protecting your downstream equipment and ensuring product quality. Without an effective magnet, you are guaranteed to have expensive downtime and contaminated products.

| Crushing Setup | Primary Magnet (After Jaw/Primary Crusher) | Secondary Magnet (After Impact Crusher) |

|---|---|---|

| Option 1 (Single Mobile Jaw) | Essential. Must be powerful enough for heavy rebar. | N/A |

| Option 2 (Jaw + Impact) | Essential. Removes the large, liberated rebar. | Highly Recommended. Removes smaller steel/wire. |

| Option 3 (Stationary Plant) | Essential. Heavy-duty, permanent magnet. | Essential. Ensures highest purity for premium RCA. |

You’ve seen three excellent options, but now you might be confused. Which one is right for your budget, your typical job site, and your customers? Making the wrong choice is a mistake you can’t afford.

The best crushing solution is the one that matches your business model. Are you a demolition contractor needing on-site mobility (Option 1)? A depot owner selling specified aggregate (Option 2)? Or a premium producer aiming for the concrete market (Option 3)?

Think about your primary goal. Are you focused on convenience and avoiding landfill fees, or are you focused on manufacturing a high-value, certified product? Your answer will point you to the right equipment investment.

| Your Business Model | Recommended Setup | Primary Goal | Investment Level |

|---|---|---|---|

| Demolition / On-site Contractor | Option 1: Single Mobile Jaw | Mobility, convenience, producing sub-base | Low – Medium |

| Dedicated Recycling Depot | Option 2: Mobile Jaw + Impact | Quality, volume, producing certified RCA | Medium – High |

| Premium RCA Manufacturer | Option 3: Stationary Plant | Maximum quality, efficiency, replacing virgin aggregate | High – Very High |

You’ve produced piles of RCA, but your potential customers are hesitant. They worry about contamination and inconsistent quality. How do you prove your product is a reliable, high-quality resource?

Guarantee RCA quality by focusing on three key areas: purity (removing contaminants), consistent gradation (sizing), and good particle shape (cubicity). This turns a waste material into a trusted product that commands a better price.

Building a market for your RCA requires building trust. You can achieve this through a commitment to quality control at every step of your process.

Concrete recycling is fundamentally about smart separation. By choosing the right crushing system for your business, removing steel and other contaminants efficiently, and focusing on quality, you can successfully turn demolition waste into a valuable, profitable resource.

Discover critical factors in steel ball configuration impacting your gold ball mill's performance. Improve grind size, throughput, and energy efficiency today.

View detailsHigh gold recovery from sulfide ores. This guide details best beneficiation processes including grinding, flotation, and advanced pre-treatment methods.

View detailsThis guide details practical beneficiation (gravity, magnetic, flotation) and equipment for high-grade ilmenite concentrate.

View detailsOptimize mineral processing! Compare spiral classifiers vs. hydrocyclones. Learn 5 differences to select ideal equipment for efficiency & beneficiation.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy