Key Benefits: Why Mobile Crushers Excel in Limestone Crushing

4015Mobile crushing plants revolutionize limestone processing, reducing operating costs, accelerating project timelines, and boosting overall productivity.

View detailsSearch the whole station Crushing Equipment

You see massive boulders at a quarry and know they need to be broken. But choosing that first machine in the line is a decision that can make or break your entire operation.

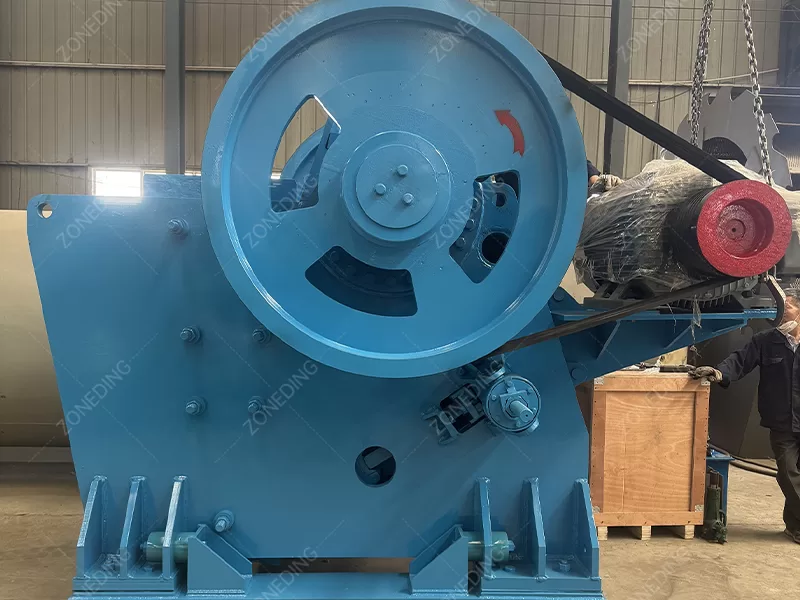

A primary crusher is the first stage in any stone production line. Its sole job is to take large, run-of-mine rock and break it down into a manageable size for the subsequent crushing stages. It is designed for power and reliability.

This machine is the foundation of your plant’s profitability. It is the gatekeeper of your entire operation. At ZONEDING, we have seen countless projects succeed or fail based on this very first choice. Getting it right means a smooth, profitable process. Getting it wrong means constant blockages, downtime, and frustration. Let’s break down why this machine is so critical and how to make the right decision.

You might think primary crushing is just about making big rocks smaller. This view misses its core strategic importance. It is not just about crushing; it’s about setting the pace and the ceiling for the entire plant.

Primary crushing is the first and most critical step in the crushing process. It acts as the “gatekeeper,” responsible for taking huge, unsized Run-of-Mine (ROM) rock and breaking it into a uniform size that downstream equipment can safely handle.

The strategic role of primary crushing can be seen in three ways. First, it protects downstream equipment. Secondary crushers like a Cone Crusher or an Impact Crusher are precision machines. They cannot withstand the impact of massive ROM rock. The primary crusher provides them with a manageable “diet” of properly sized material, preventing catastrophic damage. Second, it sets the production limit. The tons per hour (TPH) your primary crusher can process determines the maximum output of your entire plant. No matter how advanced your downstream equipment is, it cannot break this bottleneck. Third, it achieves initial “liberation.” It uses immense compressive force to fracture the rock, preparing it for the more specialized crushing and screening that follows. To ignore the importance of primary crushing is to set up your entire production line for failure.

A primary crusher looks like just a giant machine. But it solves the first and most difficult problem that every quarry and mine must face. If you don’t solve this problem, all subsequent production is impossible.

The core task of a primary crusher is to solve one problem: how to safely and reliably transform huge, irregular, and extremely hard Run-of-Mine rock into a smaller, more uniform material stream. This provides a stable and reliable feed for the entire production line.

Specifically, a primary crusher solves three core challenges. First is the size problem. The raw rock from an excavator or haul truck can be over a meter in diameter. No secondary machine can handle this. The primary crusher must have a large enough feed opening size, or “gape,” to swallow these boulders without blocking. Second is the impact problem. Dumping tens of tons of rock from a truck creates enormous impact forces. The primary crusher and its supporting feeder are built to withstand this brutal treatment. Finally, there is the reliability problem. As the starting point of the production line, the primary crusher must be able to run for long hours without failure. Any downtime stops the entire plant. Therefore, its design philosophy is all about toughness and durability, not precision or finesse.

You know you need a primary crusher, but now you face a choice. There are two main champions in this field: the Jaw Crusher and the Gyratory Crusher. They are like the heavyweight and super-heavyweight boxers of the industry. If you pick the wrong opponent, you will lose the fight.

The choice between a Jaw Crusher and a Gyratory Crusher depends almost entirely on your capacity requirement. The Jaw Crusher is the workhorse for most quarries and mobile applications, while the Gyratory Crusher is the behemoth used in the world’s largest mines and super-quarries.

The choice is very direct.

For 95% of our clients, the Jaw Crusher is the more practical and cost-effective choice.

| Feature | Jaw Crusher | Gyratory Crusher |

|---|---|---|

| Capacity | Medium to High (50-1,000 TPH) | Very High (1,500 – 10,000+ TPH) |

| Application | Quarries, recycling, mobile plants | Large mines, super-quarries |

| Initial Cost | Lower | Very High |

| Maintenance | Simpler, easier access to wear parts | More complex, major overhauls required |

| Installation | Relatively simple foundation | Major civil engineering project |

You might buy a slightly smaller primary crusher to save on the initial investment. This seemingly smart decision could cost you dearly for months or even years to come. This isn’t a small problem; it’s a chronic disease that will choke your entire plant.

Choosing the wrong primary crusher creates the most direct and fatal impact: it becomes a permanent bottleneck for the entire production line. This leads to actual output being far below design capacity, starving downstream equipment and wasting a huge amount of energy and investment.

The effects create a chain reaction. First, production is capped. If your downstream secondary crusher and screening equipment are designed for 500 TPH, but your primary crusher can only handle 300 TPH, then your plant’s maximum output is 300 TPH. All the money you invested in that extra 200 TPH of capacity is wasted. Second, operating costs increase. Frequent blockages mean downtime and using a hydraulic hammer for clearing, which not only wastes time but also damages the equipment. Finally, product quality becomes unstable. To chase tonnage, operators might be forced to open up the primary crusher’s Closed Side Setting (CSS). This results in an oversized and inconsistent discharge, putting immense pressure on the secondary crusher and negatively affecting the final product’s shape and gradation. This mistake is irreversible unless you replace the entire primary crushing station.

You are ready to make a choice. But how do you avoid the fatal mistake of buying a machine that’s mismatched for the job? It comes down to asking the right questions before you ever look at a price tag.

To choose the right primary crusher, you must first define four key factors: 1. Your raw material’s type and hardness. 2. The maximum size of rock you will feed it. 3. Your required output size. 4. Your target capacity in tons per hour (TPH).

This is the most critical decision in your plant design. At ZONEDING, our 15 engineers will always start by asking you for this information. First, the material type and hardness (e.g., limestone vs. granite) tells us how abrasive it is, which affects the selection of wear parts and the overall power required. Second, the maximum feed size dictates the required feed opening size of the crusher. This is a non-negotiable physical requirement; the opening must be larger than the biggest rock you plan to crush. Third, the desired output size helps determine the Closed Side Setting (CSS) needed to produce a feed that is suitable for your secondary crusher. Finally, your target TPH determines the physical size, power, and specific model of the machine. Answering these questions honestly prevents the most common failure: buying a crusher that is too small and creating a permanent bottleneck that strangles your entire plant’s production.

The primary crusher has done its job, but the work isn’t finished. The crushed material must flow smoothly into the next stage. If this connection is poor, it’s like dropping the baton in a relay race—it messes up the whole rhythm of production.

For a perfect connection, the primary crusher’s Closed Side Setting (CSS) must match the secondary crusher’s optimal feed size. Also, using a pre-screening feeder removes fine material before it can enter the secondary crusher, boosting efficiency.

This is a system engineering task. First, you must know that your secondary crusher (like a cone crusher) has an optimal feed size range. Feeding it rock that is too large or too small will decrease its efficiency and increase wear. Therefore, you must adjust the primary crusher’s CSS so that the majority of its output (e.g., 0-200mm) falls within the ideal receiving range of the secondary crusher. Second, setting up an intermediate surge pile or bin between the primary and secondary stages is critical. This bin acts as a buffer, ensuring the secondary crusher has a continuous, stable feed even if the primary crusher temporarily slows down to handle an extra-large boulder. Finally, using a vibrating feeder with grizzly bars for pre-screening allows fine material smaller than the secondary’s discharge setting to bypass it completely. This is a key technique for increasing efficiency and lowering costs.

You have chosen the crusher and think you are all set. But a crusher cannot work alone. It’s like a heart that needs blood vessels and other organs to function. Without that support system, even the strongest heart cannot pump blood.

A primary crusher never works alone. You must consider a complete primary crushing station that includes, at a minimum: a robust receiving hopper, a vibrating feeder for stable feeding, and a conveyor system to transport the material away.

An efficient primary crushing system is an integrated whole.

The primary crusher is the heart and foundation of your entire crushing operation. Choosing the right one based on your specific needs is the first and most critical step toward building a successful business.

Mobile crushing plants revolutionize limestone processing, reducing operating costs, accelerating project timelines, and boosting overall productivity.

View detailsDesigning a Copper Ore Beneficiation Process Design requires a rigorous analysis of micro-mineralogical characteristics rather than relying on generalized rules. The traditional approach of simply floating sulfides and leaching oxides o...

View detailsGet gold concentrates with the right equipment. Discover the 8 essential machines for placer & hard rock gold mining, and learn the secret to fine gold recovery.

View detailsMaximize efficiency in mineral processing! Uncover performance of five key crusher types, optimized for throughput, energy, and cost-saving ore reduction.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy