What Machinery is Used in Quartz Sand Production?

3897Discover essential machinery applied in a quartz sand processing line. Learn about crushers, washers, screens and separators for high purity sand production.

View detailsSearch the whole station Crushing Equipment

Your business relies on a steady supply of quality sand. But natural sand is becoming scarce, expensive, and heavily regulated. This uncertainty threatens your project timelines and your bottom line.

The fundamental difference is control. Manufactured Sand is an engineered product with consistent quality. Natural Sand is a natural resource with variable quality. For modern construction, manufactured sand is the reliable, superior, and strategic choice for your business’s future.

This is not just a technical comparison. For quarry owners, concrete producers, and construction contractors, this is a core business decision. The global shift away from natural sand is happening now. As a manufacturer of Sand Making Machines, I have helped countless companies navigate this transition. Let’s break down what this shift means for your operations, your quality control, and your profitability.

What is Natural Sand?

You are likely very familiar with this material. It has been the standard for centuries. The supply chain, however, is breaking down.

Natural sand is a fine aggregate formed by the natural erosion of rocks over millions of years. It is typically extracted from riverbeds, lakes, and seacoasts. Its quality is inconsistent, and its supply is increasingly limited by environmental regulations.

Natural sand, or river sand, consists of particles that have been weathered and transported by water or wind. This process gives the grains their characteristic smooth surface and rounded shape. While it has been historically easy to use, it comes with significant drawbacks in the modern era. The composition of natural sand deposits can vary greatly, even within the same source. This means inconsistent Gradation, fineness, and purity. It often contains undesirable amounts of silt, clay, and organic materials that can severely compromise Concrete Performance. Most critically, widespread over-extraction has led to severe environmental damage, resulting in strict government bans and regulations. This makes it an unreliable and increasingly expensive resource for any serious construction enterprise.

You see a pile of rock. I see a reliable source of high-quality, engineered aggregate that can secure your business’s future.

Manufactured Sand (or artificial sand) is a purpose-made fine aggregate produced by crushing hard rock or gravel in a controlled process. It is the modern, sustainable, and high-quality alternative to natural sand.

Unlike natural sand, we do not find manufactured sand; we create it. The process starts with selecting a suitable parent rock, like granite, basalt, or limestone. This rock is fed into a multi-stage Crushing Plant. The final and most critical stage uses a specialized VSI Sand Maker. This machine uses a rock-on-rock crushing principle to produce particles with a cubical shape, which is ideal for construction applications. Because it’s an industrial process, we have complete control over every aspect of the final product. We can precisely engineer the Gradation, control the Fineness Modulus, and manage the amount of beneficial microfines (Stone Powder Content). This results in a product that is not just a substitute for natural sand, but is often technically superior.

Your supply of natural sand is drying up. Prices are volatile. Relying on it is a massive business risk. You need a stable, long-term solution.

Yes. Switching to manufactured sand is no longer a choice but a strategic necessity. It provides a stable, legal, and high-quality raw material source that puts you in control of your supply chain and costs.

The decision to switch from natural to manufactured sand is a direct response to resource scarcity and policy risk. Governments worldwide are banning or severely restricting river sand mining to protect ecosystems. This has made Natural Sand a scarce commodity with skyrocketing prices and an unreliable supply chain. For any concrete company or contractor, this volatility is a project killer. Investing in a Manufactured Sand Production Line transforms this risk into an opportunity. You can use locally available rock, or even waste rock from other mining operations, to create a consistent supply of high-quality Construction Sand. This move insulates your business from market volatility, eliminates long-distance transportation costs, and ensures you have a legal, sustainable, and reliable source of fine aggregate for years to come.

| Factor | Natural Sand | Manufactured Sand |

|---|---|---|

| Availability | Decreasing rapidly; geographically limited. | High; can be produced anywhere with suitable rock. |

| Supply Stability | Volatile; subject to weather, regulations, and bans. | Stable and predictable; controlled by your production schedule. |

| Regulatory Risk | Very High; increasing environmental scrutiny and bans. | Low; often encouraged as a sustainable alternative. |

You’ve heard that manufactured sand is “too sharp” and will ruin your concrete. This is a myth born from using poorly produced material.

The angular Particle Shape of well-made manufactured sand creates a better interlock between particles. This results in higher Compressive Strength and more durable concrete compared to the weaker bond from rounded natural sand.

The primary difference in Concrete Performance comes down to particle geometry. The smooth, rounded particles of natural sand act like tiny ball bearings in a mix. They slide past each other easily, which can sometimes improve Workability but creates more voids and a weaker bond with the cement paste. In contrast, the angular, cubical particles of high-quality manufactured sand interlock tightly. This creates a stronger, more robust internal structure in the concrete. This superior mechanical bond leads to significantly higher compressive and flexural strength. While the angularity can slightly increase the water demand of a mix, this is easily managed through proper mix design and the use of admixtures. The result is stronger, denser, and less permeable concrete, making it the superior choice for High-Strength Concrete and demanding infrastructure projects.

| Performance Metric | Natural Sand | Manufactured Sand |

|---|---|---|

| Particle Shape | Rounded, smooth | Angular, cubical, textured surface |

| Internal Bond | Weaker; point-to-point contact | Stronger; high surface area for cement bond |

| Compressive Strength | Lower | Higher (typically 15-25% increase) |

You see sharp angles and dust as problems. I see them as features that, when controlled, create a superior product.

Use a VSI Sand Maker to create a cubical particle shape. Then, use a Sand Washer or an air screen classifier to precisely control the Stone Powder Content, turning these properties into performance advantages.

The key to high-quality manufactured sand is not to eliminate its unique characteristics, but to control them. The first step is optimizing Particle Shape. While all crushing creates angular particles, a VSI crusher is essential. It uses a high-speed rotor to throw rocks against each other, a process called “rock-on-rock” crushing. This naturally breaks the stone along its cleavage planes, resulting in a more cubical and less flaky shape. The second step is managing the fine particles (<75 microns), known as stone powder. Too much powder can increase water demand. However, a controlled amount (typically 5-10%) is highly beneficial. It fills the micro-voids between larger particles, creating a denser mix, improving pumpability, and reducing the amount of expensive cement needed. The Sand Manufacturing Process allows you to dial in this content precisely using wet or dry classification methods.

| Goal | Key Process Stage | Equipment Solution |

|---|---|---|

| Optimize Particle Shape | Tertiary Crushing / Shaping | VSI Sand Maker (Vertical Shaft Impactor) |

| Control Gradation | Screening / Classification | Multi-deck Vibrating Screens |

| Manage Fines Content | Washing / Classifying | Sand Washer or Air Screen Classifier |

A new production line is a major capital investment. You need to know if the numbers work.

While a Manufactured Sand Production Line requires a higher initial investment, its lower operational costs and stable pricing lead to a better long-term ROI compared to the volatile and high market price of natural sand.

Let’s do a direct economic comparison. The Cost per ton of sand for natural sand appears low at the point of extraction. However, the true cost includes high transportation fees, taxes, and a volatile market price that you cannot control. The total landed cost is often extremely high. In contrast, a manufactured sand plant has a significant upfront capital expenditure (CAPEX) for equipment. However, your operating expenditure (OPEX) is predictable and much lower per ton. You use local rock, eliminating most transportation costs. Your main costs are electricity, labor, and replaceable wear parts for the crushers. Because you control the production, you control the price. For most of our clients, the payback period for the initial investment is surprisingly short, often between 1 to 3 years, depending on the scale of the operation and local market prices for aggregates.

| Cost Component | Natural Sand | Manufactured Sand |

|---|---|---|

| Initial Investment (CAPEX) | Low (renting/contracting) | High (equipment purchase) |

| Transportation Cost | Very High (long distance) | Very Low (on-site production) |

| Price per Ton | High and Volatile | Low and Stable (cost of production) |

| Long-Term ROI | Low / Negative (a cost center) | High (a profit center) |

You’re ready to invest, but you need to know what a complete, effective production line looks like. Buying piecemeal is a recipe for failure.

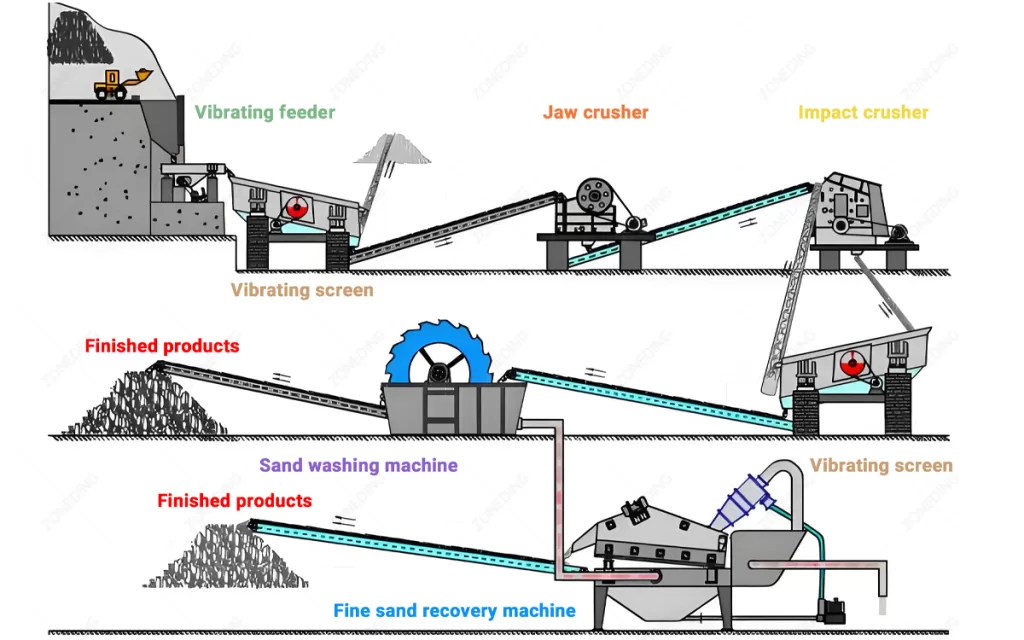

A complete line requires a system of machines: primary crusher (Jaw Crusher), secondary crusher (Cone/Impact), a VSI Sand Maker for shaping, Vibrating Screens for sizing, and a washing system.

Investing in a high-quality Eco-friendly Manufactured Sand plant is about buying a complete, integrated solution, not just individual machines. The process is a circuit. It starts with a primary crusher, typically a Jaw Crusher, to break down large boulders. The material then moves to a secondary crusher, like a Cone Crusher for hard rock or an Impact Crusher for softer rock, for further reduction. The crucial third stage is where the magic happens: the VSI Sand Maker takes the crushed stone and shapes it into a cubical product. After each crushing stage, multi-deck Vibrating Screens are used to accurately separate the material into different sizes. Finally, a Sand Washing Machine and Fine Sand Recovery Machine clean the sand and control the final fines content. As your equipment partner, we provide the technical support to design this entire circuit to work seamlessly.

| Stage | Core Equipment | Purpose |

|---|---|---|

| 1. Primary Crushing | Jaw Crusher | Reduces large raw rock to a manageable size. |

| 2. Secondary Crushing | Cone Crusher or Impact Crusher | Further reduces stone size. |

| 3. Shaping & Fine Crushing | VSI Sand Maker | Shapes particles into a cubical form. |

| 4. Screening | Vibrating Screen | Separates material into specific gradations. |

You have granite, but your competitor has limestone. You cannot use the same process and expect the same results.

The correct Sand Manufacturing Process is determined by the hardness and abrasiveness of your parent rock. Using the wrong crusher for your rock type leads to high wear costs and poor product quality.

There is no “one-size-fits-all” solution. A customized process is essential for efficiency and profitability. The most critical choice is the secondary crusher that feeds the VSI. For very hard and abrasive materials like granite, basalt, or river pebbles, a Cone Crusher is the correct choice. It uses compression crushing, which minimizes wear part consumption and operating costs. For softer, less abrasive materials like limestone, an Impact Crusher is more suitable. It shatters the rock, producing a good shape in a single pass before the material even gets to the VSI. This reduces the overall energy consumption of the plant. Choosing the wrong crusher—for example, using an Impact Crusher on hard granite—would result in extremely high wear costs and downtime. As your equipment provider, we analyze your rock first to recommend the most cost-effective and efficient process flow.

| Raw Material | Hardness/Abrasiveness | Recommended Secondary Crusher |

|---|---|---|

| Granite, Basalt, Quartz | Very Hard, High Abrasiveness | Cone Crusher |

| Limestone, Dolomite | Soft, Low Abrasiveness | Impact Crusher |

| River Stone, Gravel | Hard, Medium-High Abrasiveness | Cone Crusher or direct feed to VSI |

Switching to manufactured sand is no longer just an option; it is a vital strategic move. It secures your supply chain and puts you in control of quality and costs.

Discover essential machinery applied in a quartz sand processing line. Learn about crushers, washers, screens and separators for high purity sand production.

View detailsLearn the four key iron ore beneficiation methods to turn low-grade ore into valuable concentrate, including magnetic, gravity, flotation, and other processes.

View detailsWhat's the difference? Extraction equipment handles raw mining. Ore dressing (beneficiation) equipment refines the ore. Discover their unique functions.

View detailsHigh gold recovery from sulfide ores. This guide details best beneficiation processes including grinding, flotation, and advanced pre-treatment methods.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy