Hydraulic Cone Crusher: How it Works, Why it’s Your Crushing Solution

3887Understand hydraulic cone crushers' working principle and key features: hydraulic adjustment, overload protection, and high efficiency in mineral processing.

View detailsSearch the whole station Crushing Equipment

You have questions about producing quality aggregates. Getting the wrong answers costs you money, damages your reputation, and halts your operations. This cycle is frustrating and expensive.

This FAQ provides direct, authoritative answers to the most critical technical and business questions about aggregate production. It covers sand types, quality control, production line configuration, and investment to help you operate a profitable and efficient plant.

As a manufacturer of crushing and screening equipment, I have fielded these questions countless times from quarry operators around the world. The difference between a profitable operation and a failing one often comes down to understanding these core principles. Let’s get straight to the answers you need to succeed.

Choosing the wrong type of sand can lead to project failure. Natural sand is inconsistent, while poorly produced manufactured sand can ruin a concrete mix. This decision has significant technical and financial consequences.

Use natural sand for low-spec applications. Use washed sand to improve the quality of natural sand. Use Manufactured Sand for High-Grade Concrete and any project that requires precise control over particle shape and gradation.

The choice between these materials is a technical one, dictated by the end-use application. Natural sand, dredged from rivers or pits, is becoming scarce and often has inconsistent gradation and high impurity levels. Washed sand is simply natural sand that has been processed through a Sand Washer to remove excess silt and clay, improving its quality but not its shape or gradation. Manufactured sand is an engineered product. We create it by crushing hard rock in a dedicated VSI Sand Maker. This process gives an operator complete control over particle shape, making it more cubical, and allows for precise gradation. This level of Aggregate Quality Control is essential for modern, high-performance concrete.

| Sand Type | Source | Particle Shape | Quality Control |

|---|---|---|---|

| Natural Sand | Riverbeds, lakes, pits | Rounded, smooth | Low (variable gradation and impurities) |

| Washed Sand | Washed natural sand | Rounded, smooth | Medium (removes clay, but shape and gradation are still inconsistent) |

| Manufactured Sand | Crushed hard rock (e.g., granite, basalt) | Angular, cubical | High (precisely controlled shape and gradation) |

Your concrete customers are demanding higher standards. Failure to control key aggregate properties like gradation, particle shape, and clay content results in rejected loads and lost contracts.

Aggregate Quality Control is achieved through specific equipment at each stage. Use multi-deck Vibrating Screens for gradation, a VSI Sand Maker for shape, and a Sand Washer to control clay content.

Controlling these three parameters is the foundation of producing high-quality aggregates. They are not independent variables; they are controlled by a sequence of processing stages. First, proper Aggregate Gradation is achieved by using correctly sized screen meshes on your vibrating screens to separate the material into specific size fractions. Second, desirable cubical Aggregate Particle Shape is created in the tertiary crushing stage, specifically using a VSI crusher that uses a rock-on-rock crushing principle. Flaky or elongated particles, often produced by other crusher types, weaken concrete. Third, the Clay and Silt Content is reduced to acceptable levels (typically <3%) in the washing stage. Excess clay and silt increase water demand and prevent a strong bond between the aggregate and cement paste.

| Quality Parameter | Problem Caused by Poor Control | Equipment Solution |

|---|---|---|

| Gradation | Poor workability, high void content, low concrete strength. | Multi-deck vibrating screens with correctly selected mesh sizes. |

| Particle Shape | Reduced concrete strength, poor flow, increased water demand. | VSI Sand Maker using a rock-on-rock crushing action. |

| Clay/Silt Content | Weakens cement-aggregate bond, increases shrinkage. | Wheel or spiral Sand Washing Machine followed by a dewatering screen. |

Choosing the wrong crusher combination for your rock type leads to high wear costs, low efficiency, and poor product shape. This is one of the most expensive mistakes a quarry owner can make.

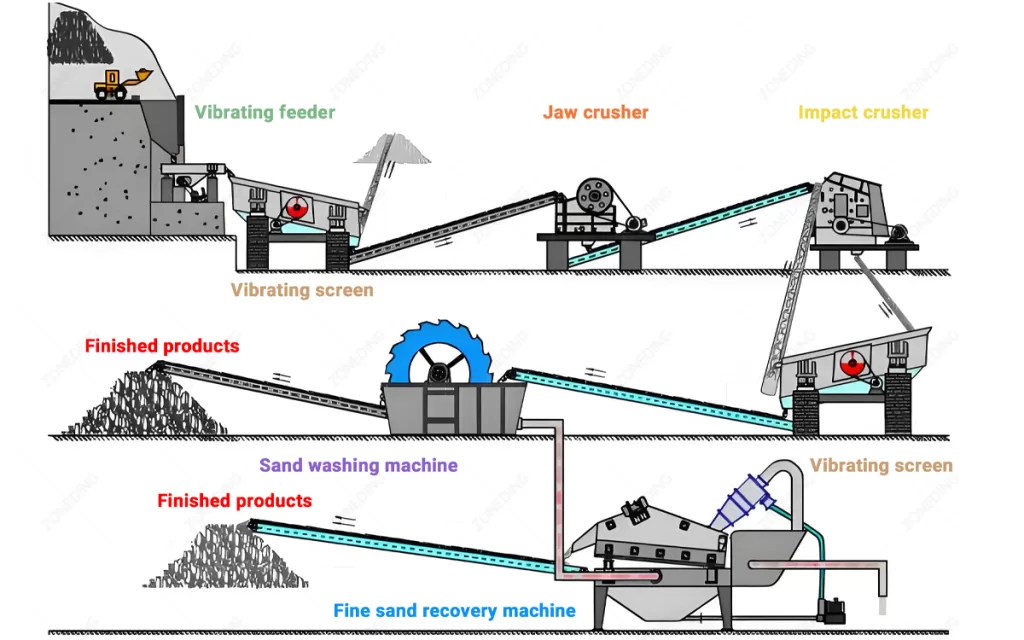

The optimal Crushing Production Line depends on your raw material’s hardness. For hard rock (granite), use a Jaw Crusher + Cone Crusher. For softer rock (limestone), use a Jaw Crusher + Impact Crusher. A VSI Sand Maker is used in the final stage for shaping.

The configuration of your Sand and Gravel Production Line is a direct function of the feed material’s compressive strength and abrasiveness. A Jaw Crusher is almost always used for primary crushing due to its large feed opening and high reduction ratio. For secondary and tertiary crushing of hard, abrasive materials like granite or basalt, a Cone Crusher is the standard choice. It uses compression to crush rock, which is highly efficient and results in lower wear costs. For softer, less abrasive materials like limestone, an Impact Crusher is preferred because it shatters the rock, producing a more cubical product in a single pass. Regardless of the primary and secondary setup, a VSI machine is often added at the end of the circuit to improve particle shape and produce a consistent sand gradation.

| Raw Material | Primary Crusher | Secondary Crusher | Tertiary / Shaping |

|---|---|---|---|

| Hard Rock (Granite, Basalt) | Jaw Crusher | Standard Cone Crusher | Short Head Cone / VSI Sand Maker |

| Medium-Hard Rock (Limestone) | Jaw Crusher | Impact Crusher | VSI Sand Maker |

| River Stone (Gravel) | Jaw Crusher / Cone Crusher | VSI Sand Maker | Not Required |

Your sand washing plant is losing valuable fine sand into the settling pond. This reduces your saleable output and creates a major environmental problem with wastewater and sludge management.

Solve this by creating an integrated, closed-loop system. Install a Fine Sand Recovery System to capture valuable fines from the washer’s overflow. Then, direct the remaining slurry to a thickener and filter press to recycle water.

The traditional method of sending wash water directly to a settling pond is both inefficient and environmentally irresponsible. A modern washing circuit solves two problems simultaneously. First, the overflow from the Sand Washer, which contains a high concentration of valuable fine sand (0.15-0.75mm), is pumped to a hydrocyclone-based fine sand recovery unit. This unit uses centrifugal force to separate the fine sand and returns it to the product conveyor, increasing your total yield by 10-20%. Second, the now fine-sand-depleted slurry is sent to a High Efficiency Concentrator (thickener). Flocculants are added to settle the solid particles. The clear water from the top is pumped back to the sand washer for reuse. This significantly reduces your freshwater consumption and the size of your settling ponds, simplifying Environmental Approval.

| Problem | Traditional (Inefficient) Method | Modern (Efficient) Solution |

|---|---|---|

| Fine Sand Loss | Overflow from sand washer goes directly to a settling pond. | Install a Fine Sand Recovery System to capture fines before the pond. |

| Wastewater | Constant demand for fresh water; large, hazardous settling ponds. | Install a thickener and filter press to recycle >90% of process water. |

Investing in a quarry is a major capital decision. Without a clear understanding of the costs and potential returns, you are making a high-risk gamble.

The total Production Line Cost includes equipment, site preparation, installation, and electrical systems. Return on investment (ROI) is calculated by subtracting your operating cost per ton from your sale price per ton, multiplied by your annual production.

Estimating the cost and return of a Quarry Investment requires a structured approach. The initial investment, or Capital Expenditure (CAPEX), is the most visible cost. This includes the price of all the Crushing Equipment, screening, and washing machines, as well as costs for civil works (foundations, roads), electrical infrastructure, and installation labor. The second component is Operating Expenditure (OPEX). This is your Cost Per Ton Calculation and includes electricity, labor, fuel for loaders, and crucially, wear parts for the crushers (jaw plates, mantles, blow bars). Your revenue is simply the market price of your aggregate multiplied by your production tonnage. The payback period is the time it takes for your net profit to equal your initial CAPEX. A detailed feasibility study is essential to accurately project these numbers.

| Cost/Revenue Component | Key Items to Include |

|---|---|

| Capital Expenditure (CAPEX) | Crushers, screens, washers, conveyors, electrical control panels, land, installation. |

| Operating Expenditure (OPEX) | Electricity, labor, wear parts, maintenance, fuel, royalties, transport. |

| Revenue Calculation | (Price per ton of Sand) x (Annual Tonnage) + (Price per ton of Gravel) x (Annual Tonnage). |

Every quarry is different. Using a standard, off-the-shelf solution for your unique raw material and market needs will result in inefficiency and lower profitability.

To get a customized Production Line Configuration Plan, you must provide your potential equipment supplier with key technical data. This includes your raw material type, max feed size, required output sizes and capacities, and site conditions.

As a manufacturer, my goal is to design a plant that maximizes your profit. To do this, I need specific information. A “one size fits all” approach does not work in the aggregate industry. The design of an efficient Sand and Gravel Production Linebegins with your rock. A lab test to determine its hardness and abrasiveness is ideal. We need to know the maximum size of the rock your loaders will feed into the plant. Most importantly, you must define your desired products: what sizes of finished aggregate do you need (e.g., 0-5mm sand, 5-10mm, 10-20mm gravel), and how many tons per hour of each product do you want to produce? With this data, my team of engineers can create a process flowsheet, select the correctly sized equipment, and provide you with a detailed technical proposal and quotation.

| Information You Provide to Us | What You Receive From Us |

|---|---|

| 1. Raw Material Type (e.g., Granite, Limestone) | 1. A detailed Process Flow Diagram (PFD). |

| 2. Maximum Feed Size (mm) | 2. A complete equipment list with technical specifications. |

| 3. Required Output Sizes and Tonnages (tph) | 3. A 2D/3D plant layout diagram. |

| 4. Site Conditions (space, power availability) | 4. A comprehensive price quotation and projected OPEX. |

Producing quality Sand and Gravel Aggregate is a matter of engineering, not luck. A systematic plant design based on your specific raw materials and market needs ensures profitability and consistent quality.

Understand hydraulic cone crushers' working principle and key features: hydraulic adjustment, overload protection, and high efficiency in mineral processing.

View detailsEfficiency in ore processing stems from the strategic balance between crushing, drying, and grinding stages. Core equipment costs typically account for a significant portion of the total investment. Achieving the target fineness with minimal ener...

View detailsThis expert guide details the process of gold gravity beneficiation, helping you optimize equipment settings and techniques for maximum recovery.

View detailsGet gold concentrates with the right equipment. Discover the 8 essential machines for placer & hard rock gold mining, and learn the secret to fine gold recovery.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy