Search the whole station Crushing Equipment

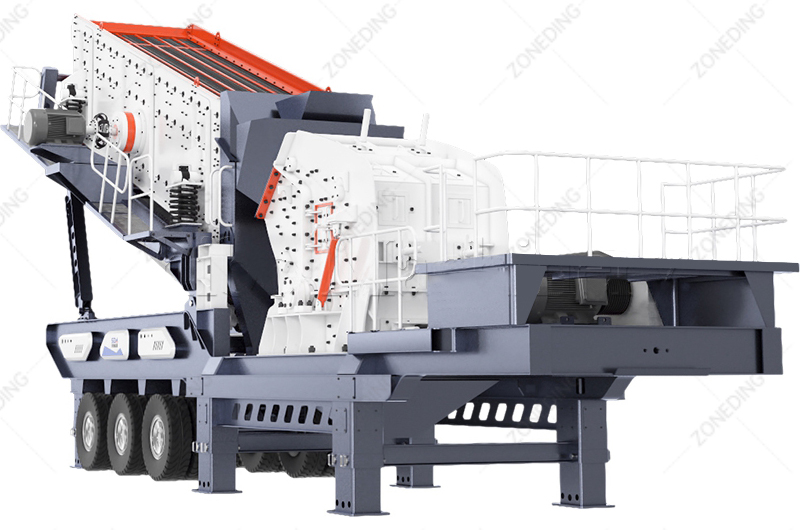

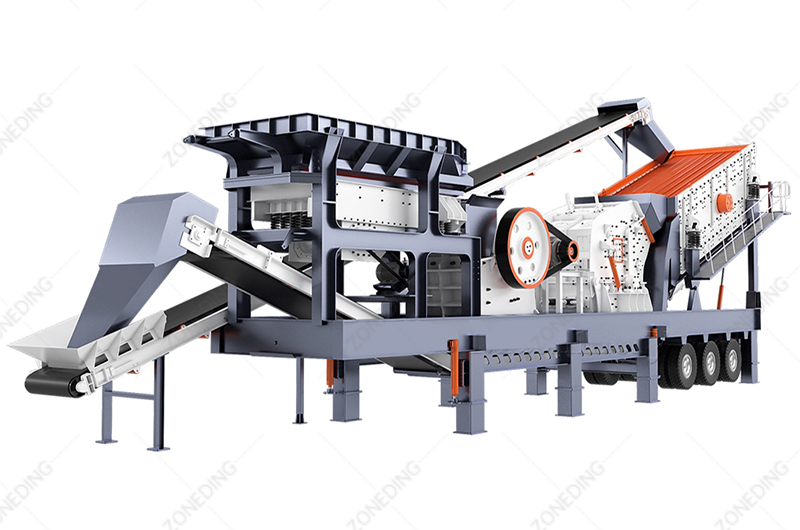

A Mobile Crushing and Screening Plant is a fully integrated system where crushing units (Stone Crusher), screening units (Vibrating Screen), feeders (Vibrating Feeder), and conveyors are all mounted on a single chassis or multiple coordinated chassis (wheeled or tracked), designed to work together seamlessly as a cohesive production line. This differs significantly from buying standalone mobile units and trying to link them yourself, as integrated plants are engineered for optimal material flow, inter-unit communication, and balanced performance from the outset.

Think of it as a pre-engineered, factory-optimized “plant on wheels (or tracks).” The key advantages of a purpose-built Mobile Crushing and Screening Plant (Mobile Crushing and Screening Plant) over a collection of individual mobile machines are:

Mobile Crushing and Screening Plants can save significant hassle and money by drastically reducing civil engineering works (foundations, structures), installation time, and relocation costs. They offer rapid deployment and the flexibility to move with the job or resource, minimizing internal haulage expenses. Savings can be substantial, especially for projects with limited lifespans or those requiring frequent moves.

| Feature | Stationary Plant | Mobile Crushing & Screening Plant | Your Savings with Mobile |

|---|---|---|---|

| Site Preparation | Extensive concrete foundations, buildings | Minimal, often just a leveled pad | Massive reduction in civil works costs & time |

| Installation Time | Weeks to months | Days to a week | Faster startup, quicker revenue generation |

| Relocation | Extremely costly and time-consuming, often impractical | Relatively easy and quick | Enables short-term projects, flexible resource exploitation |

| Internal Haulage | Fixed, material brought to plant | Can move with the quarry face or processing point | Reduced truck/loader use, lower fuel & labor costs |

| Permitting (sometimes) | Can be more complex due to permanent nature | Often simpler, viewed as temporary equipment | Faster project approvals in some jurisdictions |

| Resale Value | Lower, specialized | Generally higher, more versatile market | Better capital recovery at project end |

The upfront investment for a mobile plant might be comparable or even higher for similar capacities, but the savings on installation, site prep, and the value of flexibility often lead to a lower total cost of ownership, especially for specific project types.

Projects that benefit most are those characterized by: short to medium operational durations, the need for frequent relocation, remote or difficult-to-access sites, and applications where minimizing site footprint and environmental impact is crucial. Examples include:

“Dream teams” depend heavily on the feed material and desired end products. Common highly effective combinations include:

For Granite (hard, abrasive): Use a Tracked Jaw Crusher for primary and a Tracked Cone Crusher for secondary/tertiary stages. For Limestone (medium-soft): A Tracked Jaw Crusher or Tracked Impact Crusher for primary/secondary, with the impact crusher offering better shaping. For Construction Waste: A Tracked Jaw Crusher for primary (to handle rebar and varied feed), followed by a Tracked Impact Crusher for shaping and further reduction, often with integrated magnetic separation.

| Material Type | Primary Crusher Choice | Secondary/Tertiary Crusher Choice | Key Considerations |

|---|---|---|---|

| Granite/Basalt | Tracked Jaw Crusher (Jaw Crusher) | Tracked Cone Crusher (Cone Crusher) | Manage high abrasiveness, achieve good reduction and shape with cone. |

| Limestone/Dolomite | Tracked Jaw Crusher or Tracked Impact Crusher | Tracked Impact Crusher (for best shape) or Tracked Cone Crusher | Impact Crusher gives superior cubicity; wear is manageable. |

| Construction Waste | Tracked Jaw Crusher (robust for contaminants) | Tracked Impact Crusher (good shaping, separates materials) | Jaw handles rebar better; Impact excels at liberating materials and shaping. Magnetic separator essential. |

Choosing the right crusher type as the heart of your Mobile Crushing and Screening Plant (Mobile Crushing and Screening Plant) is paramount for efficiency and cost-effectiveness.

This varies with plant complexity. A single Mobile Crusher with an integrated screen might be operational in a few hours to a day. A multi-unit train (e.g., jaw + cone + screen) could take several days to a week for full setup, inter-unit connection, system checks, and initial commissioning to achieve stable, efficient operation .

Mobile Crushing and Screening Plants can produce a wide range of aggregate sizes, from manufactured sand (0-5mm) up to larger sub-base materials (e.g., 0-75mm), typically multiple products simultaneously (e.g., 0-5mm, 5-10mm, 10-20mm, 20-40mm). Yes, when properly configured and operated with quality crushers (especially cone or impact for shaping), the product quality (cubicity, gradation) can meet stringent international standards for concrete, asphalt, and other applications.

With the right equipment and operational discipline, mobile plants can deliver aggregates that are indistinguishable in quality from those produced by well-designed stationary plants.

Tracked units offer superior on-site maneuverability, especially on uneven or soft terrain, and faster setup between short moves. They are ideal for in-pit mobility. Wheeled (trailer-mounted) units are better for longer-distance road transport between sites, generally have lower initial purchase costs, and simpler undercarriage maintenance. They require firmer, more level ground for setup.

| Feature | Tracked Mobile Plant | Wheeled Mobile Plant | Best Fit Scenario |

|---|---|---|---|

| On-Site Mobility | Excellent, self-propelled, handles rough terrain | Limited, requires towing vehicle, needs flatter ground | Tracked: Frequent short moves within a quarry/site. |

| Inter-Site Transport | Requires low-bed trailer for long distances | Good, designed for road haulage (often street-legal with permits) | Wheeled: Projects involving regular road transport between multiple distinct sites. |

| Setup Time (Short Move) | Very Fast, drive and operate | Slower, requires positioning, leveling with outriggers | Tracked: Quick repositioning. |

| Site Condition | Adapts well to uneven, soft ground | Prefers firm, level surfaces | Tracked: Less site prep needed. |

| Undercarriage Maint. | Higher (tracks, rollers, sprockets) | Lower (tires, axles, brakes) | Wheeled: Lower routine undercarriage costs if site conditions are good. |

| Initial Cost | Generally Higher | Generally Lower | — |

Fuel/electricity consumption can be significant, varying with plant size, crusher types, material hardness, and throughput. Diesel engines are common, but electric options (grid or generator-powered) are increasingly popular for lower emissions and potentially lower operating costs where power is available. Daily maintenance is crucial and involves checks of fluid levels, belt tensions, wear parts, screen media, lubrication points, and hydraulic systems. While not overly complex, it requires diligence.

While designed for robust field use, disciplined daily maintenance is essential to maximize uptime and lifespan of a Mobile Crushing and Screening Plant (Mobile Crushing and Screening Plant).

Beyond the sticker price, consider: commissioning and training costs, transportation to site , spare parts inventory (especially wear parts), fuel/lubricant costs, potential site preparation (even if minimal), permits, skilled operator and maintenance labor, and insurance. For multi-unit plants, inter-unit conveyors might be extra.

| Model | ZDM3S1848 | ZDM3S1860 | ZDM3S2160 |

| Transportation Length(mm) | 10280 | 11480 | 11480 |

| Transportation Width(mm) | 2830 | 2830 | 3150 |

| Transportation Height(mm) | 4350 | 4350 | 4350 |

| Maximum Length(mm) | 11100 | 11800 | 11800 |

| Maximum Width(mm) | 3600 | 3600 | 3970 |

| Maximum Height(mm) | 6000 | 6000 | 6500 |

| Weight(t) | 16 | 18 | 19 |

| Tire Configuration | biax fitted | biax fitted | biax fitted |

| Vibrating Screen | 3YZS1848 | 3YZS1860 | 3YZS2160 |

Q1. What exactly is a mobile crushing station used for? How is it better than a stationary production line?

A1: The biggest advantage of a mobile crushing station is its flexibility and convenience. It doesn’t require foundation work and can be quickly relocated or moved closer to the working face. For you, this means significant savings in civil engineering costs and time, enabling faster production startup. It also reduces the internal material transport distance on site, lowering transportation costs and dust. It’s particularly suitable for projects with tight schedules, scattered sites, or those requiring phased progression.

Q2. Crawler-type vs. tire-type mobile crushing station, which is more suitable for me?

A2: It mainly depends on your mobility needs and site conditions. Crawler-type is like a tank, suitable for moving within mines or rugged construction sites, offering flexible relocation but troublesome for long-distance transport; tire-type is like a trailer, suitable for projects with better road conditions that require frequent long-distance transfers across regions. Simply put, choose crawler for on-site flexibility, choose tire for long-distance transfers.

Q3. Mobile crushing stations have several main machine types (jaw crusher/impact crusher/cone crusher). How should I choose?

A3: Choose based on your material and output requirements. Mobile jaw crushers are suitable for primary crushing, handling large, hard materials; mobile impact crushers are suitable for processing medium-soft materials (like limestone, construction waste) and produce good particle shapes; mobile cone crushers are suitable for medium-fine crushing of hard rocks (like granite, river pebbles). Not sure? Tell us your raw materials and finished product needs, and we’ll help you configure the setup.

Q4. What capacity mobile crushing station do I need? How can I estimate reliably?

A4: The capacity stated by manufacturers is usually the “maximum capacity” under ideal conditions; actual output will be lower. You need to consider: What material needs processing (hardness)? What’s the feed size? How much soil/clay content? How fine does the output need to be? Provide this information to the supplier, and let them use their experience to help you choose a model with sufficient margin. Don’t just rely on paper figures.

Q5: Is maintaining a mobile crushing station troublesome? Is the fuel/power consumption high?

A5: Routine maintenance (lubrication, tightening, cleaning) isn’t complex, but hydraulic and electrical systems require some professional knowledge. Mobile stations have compact structures, so maintenance in some areas might be less convenient than stationary plants. Fuel/power consumption is a major operating cost, highly related to equipment power, load, and power system (diesel/electric/hybrid). Choosing a diesel-electric hybrid might save more money in the long run.

Q6: What if one mobile crushing station isn’t enough? Can they be combined into a production line?

A6:Absolutely! Mobile crushing stations are very suitable for combined use, forming a complete mobile crushing and screening production line. For example, use a mobile jaw crusher for primary coarse crushing, followed by a mobile impact crusher or mobile cone crusher for medium-fine crushing, and then add a mobile screening plant for sizing. This combination can meet complex production needs with extreme flexibility.

Q7: When selecting a mobile crushing station, what key points should I focus on besides price?

A7: Price is important, but definitely not the only criterion! Pay more attention to: 1. Quality of core components (main crusher, engine/motor, hydraulic system); 2. Match between actual output and working conditions; 3. Durability of structural parts (chassis, frame); 4. Cost-effectiveness and supply of wear parts; 5. Ease and safety of operation and maintenance; 6. Manufacturer’s after-sales service and technical support capabilities.

A Tracked Cone Crusher is a Cone Crusher – a compression-type crusher that breaks rock between a gyrating mantle and a stationary concave (bowl liner) – mounted on a tracked chassis with integrated power, feeding, and c…

A Tracked Impact Crusher is essentially an Impact Crusher (a machine that uses high-speed rotating blow bars to strike material, causing it to collide with impact plates and break) mounted on a tracked chassis, integrat…

A crawler jaw crusher is a jaw crusher (a machine that uses two jaw plates to crush materials by squeezing) mounted on a self-propelled crawler chassis, integrated with feeding, conveying, and power systems. In mobile crushing op…

A mobile cone crusher is essentially a (device utilizing the principle of lamination crushing for medium-fine crushing) mounted on a mobile chassis (track or tire) and integrated with feeding, conveying, power, and other systems….

A mobile impact crusher uses a high-speed spinning rotor with “blow bars” (hammers) to strike feed material, breaking it along natural fissure lines. This differs significantly from mobile jaw crushers (compression between plates…

A tracked mobile screening plant is a machine. It separates materials into different sizes. It has a screen box. It moves on tracks. It is built on a heavy frame. This frame lets it handle rough ground. It is easy …

A mobile jaw crusher is essentially a (core equipment for primary material crushing) mounted on a movable chassis (track-mounted or wheeled), integrating auxiliary systems like feeding and conveying. Compared to stationary j…

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy