Antimony Ore Processing & Smelting: A Complete Guide

3772The Antimony Industrial Proces.Learn about modern mining methods, flotation processing, and the advanced smelting techniques used for metal extraction.

View detailsSearch the whole station Crushing Equipment

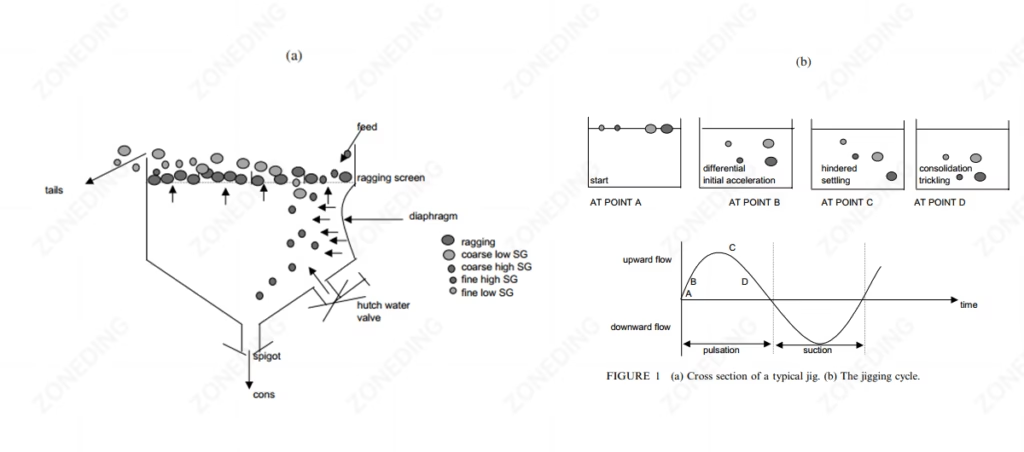

Jig Gravity Separation is a classic mineral processing method. It offers effective mineral separation. This technique uses a pulsating water flow. It separates minerals based on their density differences. The process works well for many ore types. It provides efficient and cost-effective separation. We use this method often for diverse minerals. This ensures high mineral recovery rate.

Many people simplify jigging. They assume it only separates by density. This understanding is incomplete. The actual process creates a dynamic fluidized bed. This bed acts like a dynamic system. It allows minerals to separate efficiently. This interaction of forces ensures good Jig separation efficiency. This method is a crucial part of many successful beneficiation plants.

Jig Gravity Separation is a foundational beneficiation method. It remains effective despite new technologies. This technique separates minerals by density differences. It utilizes a pulsating water flow. This process works for many ore types. It provides efficient and often low-cost separation. Its ability to handle diverse minerals makes it a core process in the mining industry.

We understand many view jigging as a simple method. They think it only uses density differences. This simplifies the process. The actual process involves creating a dynamic fluidized bed. This bed acts like a dynamic system. It allows minerals to separate effectively. This interaction of forces ensures good Jig separation efficiency. It is a cornerstone of many successful beneficiation plants.

The core of Jig Gravity Separation is a periodically changing fluidized bed. Water pulses move through the mineral bed. This action causes the bed to expand and contract. This sorts mineral particles. Heavier particles settle down. Lighter particles move up. This careful movement makes separation possible.

We have handled numerous jigging projects. These include materials from coarse coal to fine iron ore. They also include precious minerals. The process requires careful attention to detail. This ensures high Jig separation efficiency.

The Jig working principle involves two main stages:

An ideal jig bed breathes evenly. It expands and contracts uniformly. All particles inside move similarly. Uneven breathing reduces Jig separation efficiency. This process needs precise control. It maximizes mineral recovery rate. It improves concentrate grade.

The core idea of Jig Gravity Separation is more than just density. It involves creating a dynamic fluidized bed. This bed cycles through expansion and contraction. This movement sorts mineral particles. This is a precise interaction between water and solids. This careful process is key to Jig separation efficiency.

We know many consider jigging to be a simple process. The real power comes from the rhythmic water flow. This flow lifts and drops the mineral bed. This action allows particles to find their correct layer. Understanding this dynamic layering helps fine-tune the process.

A Jigging Machine operates in cycles. Each cycle has two critical stages:

A jig bed should “breathe” uniformly. It must expand and contract smoothly. Particle movement must be consistent across the bed. Any unevenness lowers Jig separation efficiency. This constant movement ensures maximum mineral recovery rate. It also helps achieve better concentrate grades.

Several forces act on particles during jigging:

These forces combine. They cause particles to stratify by density. Larger, heavier particles sink fastest. Smaller, lighter particles stay at the top. This effective sorting is why jigging remains a crucial Gravity Separation Equipment. It works well for many mineral separation tasks.

Selecting the correct Jigging Machine is crucial. Different jig types work best with specific ore characteristics. Matching the machine to your ore improves Jig separation efficiency. This helps maximize your mineral recovery rate. This selection process is a key part of Jig optimization.

Many customers prioritize a jig’s capacity. They often do not fully consider critical ore properties. Using one jig for too wide a range of ore types reduces performance. Understanding the available types helps make a better choice.

Several designs of Jigging Machine exist. Each offers specific advantages:

| Jig Type | Pulsation Mechanism | Best Suited For | Advantages |

|---|---|---|---|

| Piston Jig | Mechanical Piston | Coarse particles | Simple, robust, easy to maintain |

| Diaphragm Jig | Flexible Diaphragm | Medium to coarse particles | Even pulsation, wider particle size range |

| Air-Pulsated Jig | Air Valves | Fine particles, large capacity | Precise control, high efficiency, low energy |

Jigging Machines often feature multiple chambers or cells.

The screen plate is crucial. Its structure and hole size directly affect separation.

Choosing the right Jigging Machine type and configuration is vital. This maximizes Jig separation efficiency. It ensures your Beneficiation Equipment performs at its best.

Mineral properties are inherent to your feed material. These properties define the ultimate Jig separation efficiency. They set the maximum achievable mineral recovery rate. They also determine the potential concentrate grade. Ignoring these factors leads to poor results.

Many focus only on the jig’s capacity. They often overlook the critical role of particle size. The size distribution of the feed is very important. The density difference between minerals matters most. Trying to process a mineral that does not suit jigging limits its performance.

Jigging Machines are very sensitive to particle size.

The density difference between valuable minerals and gangue is fundamental. This difference is the driving force behind Jig Gravity Separation.

| Density Difference (Δρ) | Jigging Effectiveness | Example Minerals |

|---|---|---|

| > 1.0 g/cm³ | Excellent | Coal & Waste Rock |

| 0.5 – 1.0 g/cm³ | Good | Hematite & Quartz |

| < 0.5 g/cm³ | Difficult | Complex ores |

Particle shape is often overlooked. But it significantly affects settling behavior.

Understanding these mineral properties is critical for Jig optimization. This helps in designing the best Jigging Machine circuit. It ensures the highest possible mineral recovery rate.

The pulsation curve is the heart of the Jigging Machine. It defines the rhythm of the water flow. This rhythm controls particle movement. It ensures efficient separation. Precise control of stroke length, frequency, and cycle is crucial. This maximizes Jig separation efficiency. It improves concentrate grade.

Many operators consider these parameters as fixed settings. This is often incorrect. These parameters must work together. They create the best bed expansion and contraction. Incorrect settings lead to poor separation. They cause losses of valuable minerals. They also produce low-grade concentrates.

These two parameters are deeply linked. They determine how the bed moves.

The best combination of stroke and frequency makes the bed “boil” effectively. It should then compress quickly. Heavy minerals need enough time to move down. Fine minerals need to remain suspended at the top.

Modern Jigging Machines, especially air-pulsated ones, allow flexible adjustment. This precise control improves Jig separation efficiency. It adapts to changing ore conditions.

The shape of the pulsation curve also plays a role.

Precisely controlling these parameters is both an art and a science. It requires practice and understanding. This ensures your Gravity Separation Equipment performs optimally. It leads to the highest mineral recovery rate.

Bed thickness and hutch water velocity are critical parameters. These factors influence particle layering, impact concentrate quality, and determine valuable mineral loss in tailings. These factors directly affect Jig separation efficiency. They are essential for Jig optimization.

Many operators do not fully appreciate these subtle controls. Incorrect bed thickness can hinder separation. Improper hutch water flow can lead to losses. Fine-tuning these elements is key to achieving the best results.

The layer of material on the jig screen is called the bed. Its thickness is crucial.

| Bed Thickness | Impact on Separation | Outcome |

|---|---|---|

| Too Thin | Unstable bed, insufficient layering | Lower mineral recovery rate |

| Too Thick | Restricted movement, trapped particles | Poor concentrate grade, tailings loss |

| Optimal | Stable, distinct layers | High Jig separation efficiency |

Hutch water is water introduced below the screen plate. It flows upward through the bed. This water helps in several ways.

Adjusting bed thickness and hutch water velocity requires experience. It also needs careful observation. These are important Jig influencing factors. They ensure the Jigging Machine works at its peak.

The way feed material enters the Jigging Machine significantly impacts performance. A stable and uniform feed is essential. It creates a consistent separation environment. This maximizes Jig separation efficiency. Irregular feeding leads to fluctuating results. This causes losses and lower concentrate quality. This factor is crucial for overall Jig optimization.

Many plants overlook feed consistency. They focus on the jig itself. An unstable feed makes even the best jig perform poorly. Achieving a uniform feed ensures stable bed conditions. This allows for optimal particle layering.

Several techniques help achieve a stable feed:

| Feeding Problem | Impact on Jigging | Solution |

|---|---|---|

| Uneven Flow | Localized overloading, poor layering | Feed distributors, controlled gates |

| Fluctuating Volume | Unstable bed, variable recovery | Vibrating Feeder, variable speed pumps |

| Slimes/Oversize | Bed clogging, reduced efficiency | Pre-screening, desliming with Hydrocyclone |

Monitor the feed rate and distribution continuously. Make adjustments as needed. This proactive approach supports optimal Jig separation efficiency. It ensures the Gravity Separation Equipment performs consistently.

The design and maintenance of your Jigging Machine are vital. They ensure its long-term stable operation. They also keep the failure rate low. A robust structure and diligent upkeep are necessary. They protect your investment. They ensure continuous Jig separation efficiency.

Many plants invest in a jig. However, they neglect its structure and maintenance needs. This leads to frequent breakdowns. It causes high repair costs. It also reduces overall mineral recovery rate. Proper maintenance extends the life of the equipment. It ensures consistent performance.

A well-designed Jigging Machine is built for durability.

Proactive maintenance prevents costly breakdowns. It ensures consistent Jig separation efficiency.

| Component | Maintenance Action | Benefit for Jigging |

|---|---|---|

| Screen Plates | Inspect for wear, blinding, replace as needed | Maintains Jig separation efficiency, prevents loss |

| Bearings/Seals | Lubricate, inspect for wear, replace worn parts | Prevents breakdowns, ensures smooth operation |

| Structure | Check for cracks, corrosion, tighten fasteners | Ensures stability, prolongs equipment life |

| Bed Stones | Check level, clean, replenish | Optimizes particle layering, improves mineral recovery rate |

Operators should know how to identify and address common Jig troubleshooting problems:

Our machines at ZONEDING are designed for durability and ease of maintenance. This ensures a long service life. It helps you maintain a high mineral recovery rate. It keeps operating costs low.

Optimizing the Jig Gravity Separation flow is crucial. It means integrating all the factors discussed earlier. The goal is to achieve the best mineral recovery rate. It also aims to reduce energy consumption. This requires a systematic approach. It involves more than isolated adjustments. This is the essence of Jig optimization.

Many operations make changes without a full understanding. This often leads to new problems. A holistic view considers the entire beneficiation circuit. It looks at how jigging fits within it. This strategic optimization ensures long-term efficiency.

Combine insights from feed properties, operational parameters, and equipment.

Jigging Machines are energy-efficient compared to other methods. However, further savings are possible.

For Iron Ore Beneficiation, jigging can be a primary or pre-concentration step.

This integrated approach ensures the entire mineral processing solutions circuit works in harmony. It maximizes efficiency and profitability.

Jig Gravity Separation is a highly versatile method. It applies to many different minerals. It is a fundamental process in various mining sectors. Its effectiveness comes from separating minerals based on density. This makes it suitable for ores where other methods are less efficient or too costly. This method is a key piece of Gravity Separation Equipment. It supports a wide range of Jig applications.

We have observed jigging used successfully for both common and rare minerals. Its adaptability makes it a valuable tool. It helps achieve high mineral recovery rate across different industries.

Jigging Separation is employed globally for many ores:

The wide range of Jig applications highlights its importance. It is a reliable tool for various mineral separation challenges. It contributes to efficient and sustainable mining.

Optimizing Jig Gravity Separation is complex. It needs specialized knowledge. It requires real-world experience. You need a partner who truly understands your challenges. ZONEDING provides tailored mineral processing solutions. This accelerates your path to higher efficiency. It ensures your project’s success.

Many companies try to handle everything in-house. This can be slow. It can also be costly. A professional technical partner offers proven expertise. They provide state-of-the-art Jigging Machine technology. They offer comprehensive support.

ZONEDING has been a leader in mineral processing since 2004. We provide Beneficiation Equipment and solutions worldwide. We specialize in customized Jig optimization strategies.

We are committed to helping you achieve your goals. Our solutions focus on:

Partner with ZONEDING. You can unlock new levels of efficiency and profitability. Our proven technology and experience will guide you.

Question 1: What is the core idea behind Jig Gravity Separation?

The core idea involves creating a dynamic fluidized bed. Water pulses cause particles to separate. Heavier minerals move down. Lighter minerals move up. This process needs precise control for good Jig separation efficiency.”

Question 2: How does particle size affect Jig separation efficiency?

Jigging Machines are sensitive to particle size. A narrow size range in the feed is best. An ideal ratio of largest to smallest particles is 3:1 to 5:1. A wide range reduces separation quality. It causes losses of both heavy and light minerals.

Question 3: What are the key parameters for adjusting a Jigging Machine?

Key parameters include stroke length, frequency, and hutch water. Stroke and frequency control the bed’s movement. Hutch water helps separate fine particles. Adjusting these fine-tunes the Jig separation efficiency. It matches specific ore properties.

Question 4: Can Jig Gravity Separation be automated?

Modern Jigging Machines can be automated. This uses sensors for bed density and pressure. It automatically controls concentrate discharge. It also adjusts pulse parameters. Automation reduces human error. This leads to more stable and optimal Jig separation efficiency.”

Question 5: What ores are typically processed by Jigging Separation?

Jigging Separation is suitable for a wide range of minerals. These include coal, iron ore, tin, gold, and manganese. The method works best for ores with clear density differences between valuable minerals and gangue. This is a versatile Gravity Separation Equipment.”

Jig Gravity Separation is a foundational process. It remains highly effective for mineral separation. Its success relies on understanding many factors. These include mineral properties, precise operational control, and robust equipment maintenance. Optimizing these elements ensures high Jig separation efficiency. It also maximizes the mineral recovery rate. It improves concentrate grade.

The intricate nature of this process necessitates a thorough analysis of feed characteristics and careful adjustment of parameters. It greatly benefits from modern automation technologies, as even minor adjustments can yield significant gains. ZONEDING provides the expertise and equipment to fine-tune your Jigging Machine, ensuring its optimal performance.

ZONEDING has been a leader in mineral processing since 2004. We provide Beneficiation Equipment and solutions worldwide. We specialize in customized Jig Gravity Separation technologies. Our machines are known for reliability, efficiency, and top performance. We offer full-process solutions. This includes design, manufacturing, installation, and after-sales support. We help you achieve superior Jig optimization. We ensure your investment is a success.

Contact us today. Our experts can help design or optimize your Jig Gravity Separation plant. Maximize your mineral’s value with ZONEDING’s proven technology and experience.

The Antimony Industrial Proces.Learn about modern mining methods, flotation processing, and the advanced smelting techniques used for metal extraction.

View detailsLearn the step-by-step process for gold extraction from oxidized ore. We define this mine type and list the key equipment for each stage of the operation.

View detailsEssential machinery for cyanidation gold extraction: crushers, mills, leaching tanks, and recovery systems vital for efficient gold recovery from ore.

View detailsChoosing the right crusher is key. We compare cone, VSI, and impact crushers for producing consistent, high-quality fines for any project.

View details