Waste Cement Blocks to Quality Aggregates: What Equipment and Processes?

4078Unlock construction waste value! Guide to converting cement blocks into quality recycled aggregates with crushers & screens.

View detailsSearch the whole station Crushing Equipment

Selecting the right Mineral Processing Crusher is a critical decision. It directly impacts the efficiency and cost of the entire production line. Crushing prepares materials for further processing. This step determines the final product quality. Incorrect Crusher Selection leads to operational issues and higher costs. This guide outlines five core Types of Crushers. It details their working principles and best applications. This information assists in making informed decisions for mineral processing operations.

Industrial experience highlights the critical role of proper Crusher Selection. It confirms that understanding mineral properties, production goals, and budget limits is essential. Long-term maintenance also requires consideration. This article presents insights into these five crushers. It is based on extensive practical application in the field.

Crushing represents the initial and fundamental stage in mineral processing. This process reduces large ore pieces into smaller, manageable sizes. This prepares the material for subsequent stages. These stages include grinding, beneficiation, and refining. The efficiency of crushing directly influences the entire plant’s performance. It impacts energy consumption, downstream equipment wear, and final product quality.

Optimal crushing leads to increased efficiency in subsequent processes like grinding. It also enhances the effectiveness of separation methods. The generation of fine particles during crushing requires careful management. Excessive fines can lead to over-grinding. This results in wasted energy. It can also reduce recovery in some beneficiation processes. Effective Ore Crushing balances particle size reduction with fine generation. This ensures optimal results for the overall operation.

Crushing involves more than merely reducing rock size. It requires precise size control. It focuses on particle shape. It also impacts energy use and wear rates. These factors collectively contribute to the economic viability of a Mineral Processing Plant.

Jaw Crushers are extensively employed for primary crushing. They handle hard, abrasive, and large ore blocks. These machines operate on a compression principle. They efficiently reduce large rocks to smaller sizes. This protects other equipment within the crushing circuit. Their robust construction renders them suitable for initial size reduction stages.

A common perception is that Jaw Crushers simply break large rocks. Their significant value lies in their function as the primary crushing stage. They act as a protective barrier for more sensitive downstream equipment. They effectively manage very large and hard ore pieces. This constitutes their core function. Improper application includes feeding materials with high clay content. This leads to frequent blockages and increased wear. Another error involves using them for overly abrasive materials without prior ore property analysis. This can shorten jaw plate life. It consequently increases operational costs significantly.

Jaw Crushers excel in compressive breaking. This makes them ideal for hard, abrasive ores. They are recognized for stability and high energy efficiency under these conditions. However, their product shape often tends to be flaky or elongated. This characteristic may not be optimal for all aggregate applications.

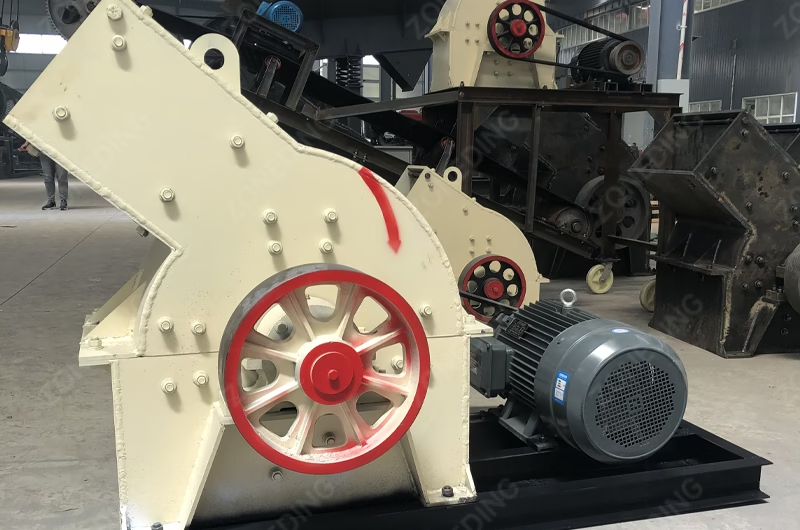

Hammer Crushers are highly effective for materials of medium to low hardness. They are suitable for brittle materials and those with low moisture content. These machines utilize high-speed rotating hammers. They break material through impact, shear, and grinding actions. They demonstrate efficiency in achieving high reduction ratios. They can produce fine products in a single pass.

Industrial practice indicates Hammer Crushers are effective for rapid, fine crushing and efficient pulverization. They achieve high reduction ratios. They can break large materials into very small sizes. They can even directly produce fine powder. In some applications, they can substitute for certain grinding equipment. A common misapplication involves using them for hard or abrasive materials. This results in rapid hammer wear. It causes high maintenance costs. Another issue arises when using them for materials with high moisture or stickiness. This can lead to blockages in screen plates and the crushing chamber. It consequently interrupts production.

Hammer Crushers are recognized for their high reduction ratio. They can process materials to a desired fine product size quickly. They are suitable for applications where product shape is not critical. They can also generate fine powders.

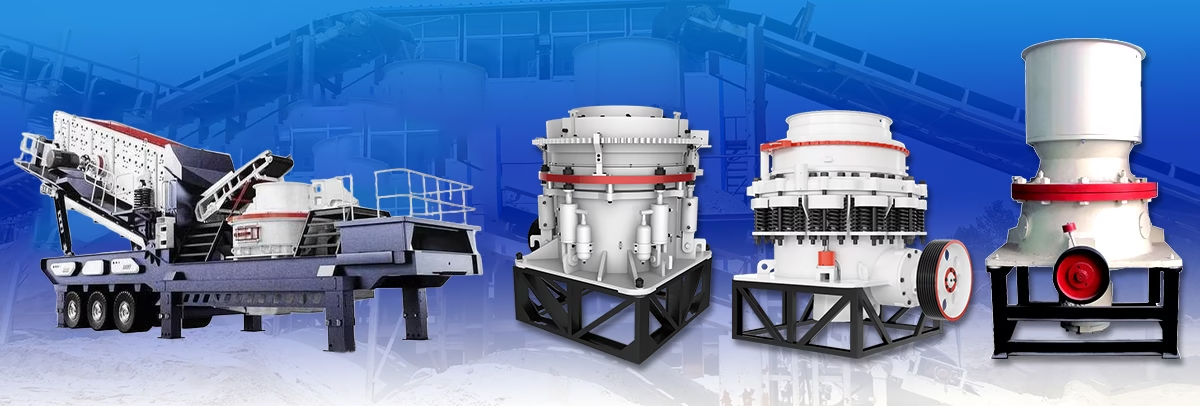

Cone Crushers are utilized for medium and fine crushing applications. They effectively handle hard and abrasive materials. These machines operate on a layered crushing principle. Material is crushed against itself within the chamber. This process generates a higher proportion of cubic-shaped particles. This method proves effective for secondary or tertiary crushing stages. It prepares material for subsequent grinding or final product use.

The fundamental concept of a Cone Crusher involves layered crushing. Material undergoes compression against itself. This is distinct from simple compression. This action produces more cubic particles. For achieving high efficiency, the crushing chamber should maintain a full condition. This is referred to as “choke feeding.” It facilitates particle-on-particle breakage. Industrial observations indicate that uneven feeding can lead to non-uniform wear within the crushing chamber. This consequently reduces efficiency. Another misapplication involves using a single cone crusher for all stages. This includes coarse, medium, and fine crushing. This practice results in inadequate product size control or excessive energy consumption. Neglecting regular inspection of hydraulic overload protection systems can also lead to internal damage if uncrushable objects enter the chamber.

Cone Crushers are effective for particle shaping. They improve the cubicity of the product. This characteristic enhances the quality of aggregates for concrete and asphalt mixes. Their automated hydraulic adjustment capabilities render them suitable for modern mining operations.

Impact Crushers offer high efficiency and good particle shape. These are categorized into Horizontal Shaft Impact (HSI) Crushers and Vertical Shaft Impact (VSI) Crushers. Although both are impact crushers, their operating principles and applications differ. HSI crushers predominantly employ a “steel-on-stone” impact mechanism. VSI crushers primarily utilize “stone-on-stone” impact, with some capacity for “stone-on-metal” action.

Impact crushers deliver high reduction ratios and excellent product shape. However, their application necessitates careful consideration of material properties. For HSI crushers, a common attraction is their high reduction ratio and superior product shape. However, the sensitivity of HSI to material abrasiveness is often underestimated. Employing HSI for hard, abrasive materials like granite or quartzite results in rapid wear of blow bars and impact plates. This consequently leads to very high operating costs. For VSI crushers, a frequent misapplication is treating them as universal fine crushers. Their use for wet, sticky, or high-clay content materials can cause blockages. This results in inefficient operation.

Roll Crushers (including single roll, double roll, and High-Pressure Grinding Rolls – HPGR) are effective in specific applications. They are suitable for sticky materials. They also process materials with high moisture content. These crushers are suitable for brittle materials. They are also employed when strict control over over-crushing is required. They operate through compression and shearing. This mechanism minimizes over-grinding.

The crushing capability of Roll Crushers is sometimes underestimated. When processing very hard, abrasive minerals, the specialized requirements for roll surface materials may be overlooked. This leads to rapid roll wear and frequent maintenance. Double roll crushers can experience slippage or bouncing when handling large, hard materials. This consequently reduces crushing efficiency. The roll crusher operates with a controlled force. It achieves high efficiency for specific material types.

Roll Crushers are effective for controlled size reduction. They minimize over-crushing. This is critical for minerals where particle integrity is important. HPGR further extends this principle. It achieves high energy efficiency and reduction ratios.

The selection of the appropriate Mineral Processing Crusher necessitates a careful comparison. It involves evaluating their performance against specific criteria. These include capacity, energy consumption, particle size control, and maintenance costs. Each crusher type presents distinct benefits and challenges. This comparison aids in making an informed Crusher Selection.

Understanding these distinctions is crucial. It ensures the chosen equipment meets production goals. It also facilitates effective management of operational budgets. No single crusher type is universally optimal. The best choice depends on specific ore properties and production requirements.

| Crusher Type | Primary Application | Capacity (Relative) | Energy Consumption (Relative) | Particle Size Control | Maintenance Costs (Relative) | Wear Parts |

|---|---|---|---|---|---|---|

| Jaw Crusher | Primary Crushing | High | Moderate | Coarse (Flaky product) | Moderate | Jaw plates, side liners |

| Cone Crusher | Secondary/Tertiary Crushing | High | Moderate-High | Fine (Cubic product) | Moderate | Mantle, concave |

| Hammer Crusher | Soft/Medium-Hard Crushing | Medium-High | High | Fine (Irregular product) | High | Hammers, grate plates |

| Impact Crusher (HSI) | Secondary (Non-abrasive) | High | High | Fine (Cubic product) | Very High (Abrasive Ore) | Blow bars, impact plates |

| Impact Crusher (VSI) | Fine (Manufactured Sand) | Medium | High | Very Fine (Cubic product) | Moderate-High | Rotors, wear plates |

| Roll Crusher | Special (Sticky, Brittle) | Low-Medium | Low-Moderate | Fine (Controlled fines) | Moderate | Roll surfaces |

This comparison facilitates a balanced decision. It considers both technical performance and economic implications. This process is integral to effective Crusher Selection.

The selection of the appropriate Mineral Processing Crusher is a complex decision. It necessitates careful consideration of multiple factors. These include the characteristics of the ore. Production goals and the available budget are also critical. A well-considered approach ensures optimal performance and cost-effectiveness.

Industrial insights suggest basing decisions on comprehensive analysis. Avoid relying solely on assumptions or prevailing trends. A suitable crusher setup optimally matches specific operating conditions. This leads to sustainable profitability.

This systematic approach minimizes risks. It ensures Mining Crushing Equipment is optimized for specific operations. It aims for long-term profitability.

Modern crushing technology is undergoing rapid evolution. Two major trends significantly influence this development: intelligence and environmental sustainability. These trends impact the design, operation, and maintenance of Mineral Processing Crushers. Their objective is to enhance efficiency, reduce costs, and minimize environmental impact.

These changes are under close observation. Manufacturers are integrating advanced technologies. This includes sensors, automation, and data analytics. Environmental considerations also drive innovation. This leads to more sustainable crushing practices.

These trends contribute to more sophisticated and sustainable Crushing Equipment. They enable more efficient Ore Crushing. They also support environmentally sound mining practices. ZONEDING integrates these advancements into its products. This helps customers maintain competitiveness.

Each mining project possesses unique characteristics. These include specific ore properties, site conditions, and production goals. Standard crushing equipment may not always yield optimal results. Customized Crushing Equipment Optimization and process solutions are frequently necessary. They maximize efficiency and profitability.

A one-size-fits-all approach is rarely effective. Tailored solutions consider all specific factors. This ensures the crushing circuit performs optimally. ZONEDING specializes in providing these bespoke solutions.

Partnering with ZONEDING offers a dedicated team. This team works to deliver a crushing solution perfectly suited to a project. It aims to ensure maximum returns on investment.

Question 1: Why is Crusher Selection important in mineral processing?

Crushing is the initial stage in mineral processing. It prepares material for further treatment. Correct Crusher Selection directly affects the efficiency and cost of the entire production line. It ensures optimal material size and shape for downstream processes.

Question 2: What are the main Types of Crushers for coarse crushing?

Jaw Crushers are primary choices for coarse crushing. They handle hard and large ore blocks. These machines use a compression method. They reduce large rocks to smaller sizes efficiently. This protects other equipment.

Question 3: Which crusher is best for improving product particle shape?

Cone Crushers and Impact Crushers are effective for particle shape improvement. Cone Crushers use layered crushing for cubic shapes. Impact Crushers (especially VSI) excel at producing manufactured sand with good particle shape.

Question 4: How does material hardness affect Crusher Selection?

Material hardness is a key factor for Crusher Selection. For very hard and abrasive materials, Jaw Crushers and Cone Crushers are suitable. Hammer Crushers and Impact Crushers (HSI) are less suitable for hard, abrasive materials due to high wear part costs.

Question 5: What are the advantages of Roll Crushers?

Roll Crushers are ideal for sticky, wet, or brittle materials. They achieve low over-crushing. This preserves the integrity of some minerals. They offer good control over product size. They are energy efficient for certain applications.

The selection of the optimal Mineral Processing Crusher requires detailed analysis. It necessitates careful consideration of ore properties, production goals, and budget. Each crusher type—Jaw Crusher, Hammer Crusher, Cone Crusher, Impact Crusher, and Roll Crusher—possesses unique strengths. Each also has specific applications. Understanding these distinctions is fundamental to successful Crusher Selection.

The recommendation is to always conduct thorough mineralogical analysis. Perform crushing tests. Seek advice from experienced industry experts. This approach helps avoid costly mistakes. It ensures optimal efficiency and profitability for any project.

ZONEDING has been a leader in mineral processing since 2004. It provides a full range of Crushing Equipment and solutions. It serves clients worldwide. ZONEDING specializes in customized crushing solutions. Its machines are recognized for reliability, efficiency, and top performance. Full-process support is offered. This includes design, manufacturing, installation, and after-sales service. ZONEDING assists in achieving superior Crushing Equipment Optimization. This ensures a successful investment.

Contact us today. Experts can assist in designing or optimizing any Mineral Processing Crusher plant. Maximize mineral value with ZONEDING’s proven technology and experience.

Unlock construction waste value! Guide to converting cement blocks into quality recycled aggregates with crushers & screens.

View detailsLearn how magnetic separation uses magnetism and froth flotation uses surface chemistry, plus see their key applications.

View detailsDiscover the 7 crucial aspects of mobile crushing technology, from its benefits and applications to key operational considerations for peak efficiency.

View detailsThe kaolin purification process is a sophisticated system designed to transform raw clay into a high-value industrial mineral. Success is not about extracting a small amount of metal; it is about removing trace impurities that dictate the final p...

View details