Pyrite in Ore: Friend or Foe? A Guide to Processing & Equipment

3577It's easy to mistake pyrite for gold. This guide shows you a simple streak test and other quick checks anyone can perform to identify fool's gold.

View detailsSearch the whole station Crushing Equipment

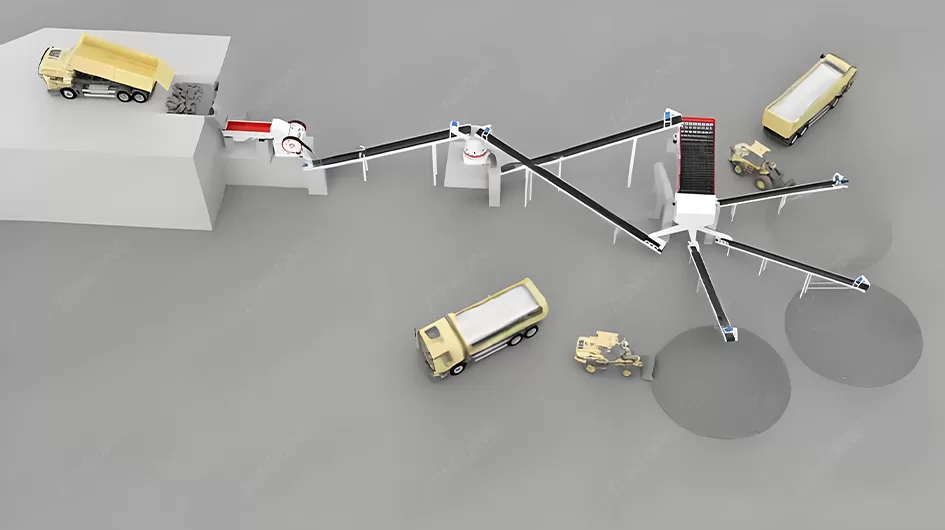

The total investment for a stationary crushing plant is a complex calculation. Equipment costs usually represent only 40% to 50% of the total project budget. Other major expenses include civil engineering, power infrastructure, land permits, and environmental systems. This guide breaks down every expense from purchase to operation in 2026. Understanding these details helps avoid financial gaps during construction. I provide this data to help calculate a realistic budget for large-scale stone production. I want to ensure every investor knows the real numbers before starting a project.

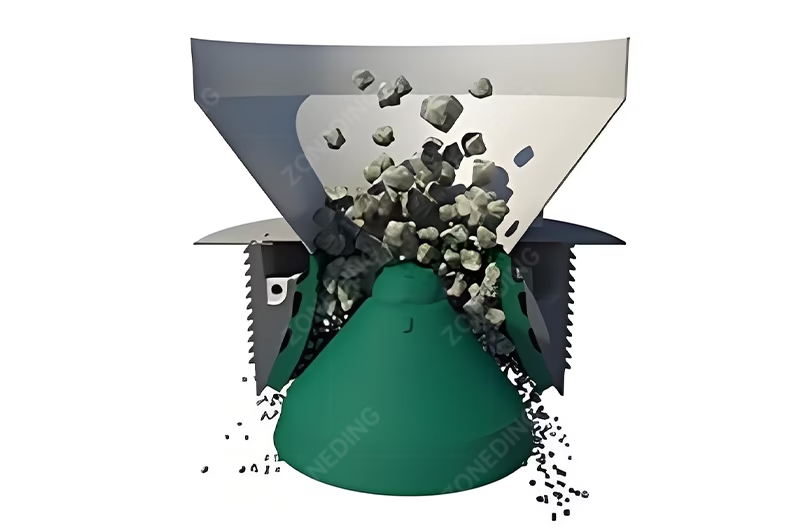

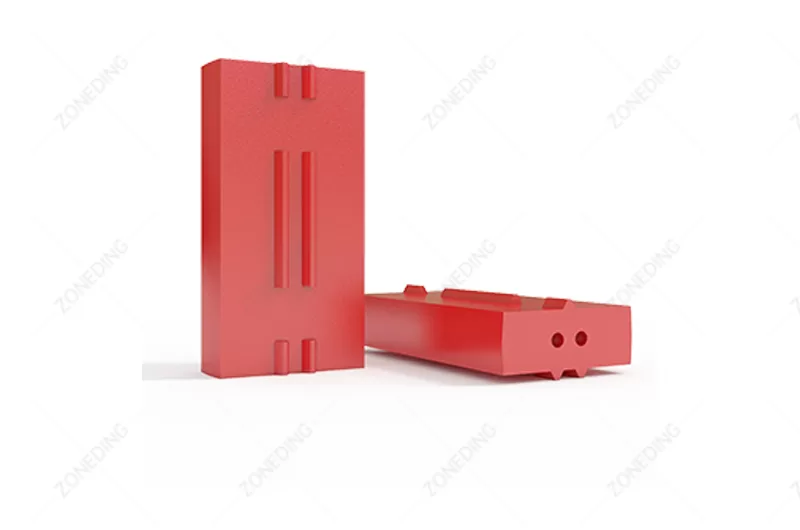

Core machines are the primary expense in any mineral processing project. Primary crushing requires a heavy-duty Jaw Crusher. A medium-sized unit costs between $30,000 and $130,000. Secondary and tertiary crushing require Cone Crushers or impact units. A high-efficiency hydraulic cone crusher costs between $65,000 and $250,000. These machines handle hard materials like granite. Vibrating Screens separate the final aggregate sizes. A large triple-deck screen costs between $16,000 and $48,000. I have seen many people underestimate the cost of high-quality motors.

Equipment selection must match the target hourly output. Small plants producing 100 tons per hour have lower entry costs. Large plants producing 500 tons per hour require multiple large machines. Motor power also influences the initial purchase price. Higher power means more production but higher costs. Buying from a direct manufacturer provides a Full set quotation for sand and stone production line without markups. I recommend checking the steel grade before buying. Thicker frames cost more but they last much longer. Cheap machines often break under the stress of heavy rocks.

The configuration changes based on material type. Soft stones like limestone use impact crushers to reduce cost. Hard stones like basalt require cone crushers to minimize wear. Each machine needs a specific motor and drive system. The price includes the main unit and the electric control box. Spare parts for the first six months should be part of the initial budget. This includes liners, jaws, and belts. I design layouts to optimize machine placement. This reduces the number of conveyors needed. Fewer conveyors lower the total equipment price. 2026 pricing reflects changes in steel and component costs. Direct factory sourcing remains the most cost-effective method for B2B buyers. I always suggest keeping a set of wear parts at the site. This prevents a two-week shutdown for a simple part replacement.

| Machine Type | Function | Price Range (USD) | Benefit |

|---|---|---|---|

| Jaw Crusher | Primary Crushing | $35,000 – $130,000 | Large feed size |

| Cone Crusher | Secondary Crushing | $65,000 – $260,000 | High hardness rock |

| Vibrating Screen | Sizing | $16,000 – $48,000 | Precise sorting |

Stationary plants offer superior stability for long-term projects. Heavy concrete foundations absorb the massive vibrations of large Stone Crushers. This stability reduces stress on machine frames. It extends the mechanical life of the equipment by 30%. Stationary designs also allow for much larger feed sizes. They can handle rocks that mobile units cannot process. This makes them ideal for large-scale quarrying. I believe stationary plants are the backbone of the infrastructure industry. They provide a steady supply of material year after year.

High production capacity is the main reason to choose stationary setups. These plants easily exceed 500 or 1000 tons per hour. They provide more space for multiple screening decks. This allows for more precise product sizing. Maintenance is also easier. Large overhead cranes can be installed in a fixed building. This speeds up the replacement of Crusher wear parts. I often see workers finish repairs twice as fast in a fixed plant. The safe working environment reduces accidents and insurance costs.

The long-term operating cost is significantly lower. Electricity from the grid is cheaper than diesel fuel. Stationary plants use electric motors for everything. They do not need expensive hydraulic systems found in mobile units. The layout is fully customizable. I can design the plant to fit the specific shape of the mountain. This optimizes gravity feeding and reduces conveyor use. For a project lasting more than five years, the stationary plant offers the best value. I have built many plants that are still running after 15 years. This durability is the best way to protect your investment.

Civil engineering is often a large surprise for new investors. A stationary plant needs heavy concrete foundations. These support the weight and vibration of the Crushing Equipment. Workers pour thick reinforced concrete deep into the ground. If the foundation is weak, machines move and break. In many projects, foundations reach 30% of the total budget. This is why a Detailed budget for mining plant construction must include local cement prices. I always tell clients to spend more on concrete now to avoid massive repair costs later.

Steel platforms are also necessary for maintenance. These structures allow workers to reach screens safely. Steel prices change every day. A 300-ton-per-hour plant needs 50 to 80 tons of structural steel. This includes catwalks and supports. Skid-mounted designs can reduce concrete work but increase steel tonnage. Professional engineering designs minimize the total concrete volume. I provide clear foundation drawings to my clients to help them save on materials. Good drawings ensure workers do not waste rebar or cement.

Foundations for primary crushers are the most complex. They must handle the impact of trucks dumping raw rock. Foundations for vibrating screens must manage high-frequency movements. This requires specialized rebar patterns. Steel platforms must be bolt-connected for easy repair. Welding on site increases labor costs. Pre-fabricated steel parts from the factory are faster to install. They ensure the holes align perfectly with the machines. 2026 labor costs for concrete work vary by region. Site preparation also includes drainage systems. These prevent water from pooling around machine bases. Good drainage extends the life of the concrete. I have seen foundations fail just because water sat in the pit for too long.

Land and legal rights are the first expenses you will face. Land leasing costs vary by country. The plant needs space for machines and stockpiles. Finished products like gravel and sand take up a lot of room. Trucks need space to turn and park. If the land is not flat, grading is expensive. Hiring bulldozers for site preparation costs between $5,000 and $20,000. Mining rights and environmental permits are time-consuming. I recommend starting the permit process at least six months before you want to buy equipment.

Operators pay government fees to extract stone. These fees are based on the total tons mined. Environmental impact studies are mandatory in 2026. Plants must prove they will not pollute water or air. Legal fees and consultants add $10,000 to $50,000 to the budget. Checking local zoning laws is a critical step. Permit processes can take six months to a year. This delay is a hidden cost. Investors must pay for the land while waiting for the permits. I have seen projects fail because the owner forgot to check noise limits in the area.

Some regions require a restoration bond. This money ensures the land is fixed after the mine closes. Environmental permits in 2026 include water usage rights. If the plant washes sand with a Sand Washing Machine, it needs water permits. It also needs a plan for waste water. Dust control permits are also strict. Authorities check the plant for dust levels every month. Fines for non-compliance are very high. Total startup legal costs can reach 5% of the total investment. It is better to hire a local expert for this stage. They know the specific rules of the region. I can provide the technical data needed for these permit applications.

Electricity is the main power source for stationary plants. Most sites are far from the power grid. Operators pay to bring high-voltage lines to the site. This involves utility poles and copper cables. A Transformer expansion application fee is required if the grid is weak. A 500kW plant needs a 1000kVA transformer. This handles the high startup current of the motors. I have seen plants stop running because the transformer was too small for the peak load.

Wiring the plant is a major expense. A centralized control room contains the MCC. This includes starters and breakers for every machine. High-quality copper cables are expensive. A medium plant needs hundreds of meters. Using VFDs increases the initial cost but saves power later. Budgeting at least $20,000 for electrical installation is common for small plants. I recommend using armored cables to prevent damage from rodents or heavy machines. Good wiring prevents fires and long shutdowns.

Cable thickness depends on the distance from the transformer. Long distances require thicker cables to prevent voltage drop. Voltage drop causes motors to overheat and fail. Protection from lightning is also necessary in mountainous areas. Grounding systems protect the electronics in the control room. 2026 electrical standards require better insulation. This prevents fires in dusty environments. Automation adds to the electrical cost. Sensors on the conveyor belts detect slips or tears. These sensors need their own low-voltage wiring. The control room should be dust-proof and air-conditioned. Heat is the enemy of electrical components. A cool control room reduces the chance of a summer shutdown. Total electrical costs can reach 10% of equipment value.

Conveyor belts link all the machines in your plant. Total length depends on the site layout. Longer conveyors mean larger stockpiles. This is good for selling stone but increases cost. Operators pay for the rubber belt and the rollers. They also pay for the motors and the steel frames. A standard 800mm wide conveyor costs $150 to $250 per meter. A large plant might spend $50,000 on the conveyor system alone. I use 3D software to plan the shortest routes to save you money.

Material type changes the Operating expenses of crushers. Hard rocks wear down belts faster. High-abrasion rubber belts cost 20% more. The width of the belt is determined by the hourly capacity. A 500-ton-per-hour line needs wider belts. High-quality rollers reduce friction and power use. Conveyor covers are often required by law. These prevent dust from blowing away. Covers add 15% to the conveyor cost. I suggest installing covers from the start to avoid complaints from neighbors.

Scraping systems are also necessary. These clean the belt as it returns. Without scrapers, fine stone builds up under the rollers. This causes the belt to wander and tear. Safety pull-cords are a legal requirement in 2026. These allow workers to stop the belt instantly in an emergency. Walkways alongside the conveyors allow for safe inspection. These steel walkways increase the weight of the conveyor frame. Stronger frames cost more but prevent bending. Bending frames cause the belt to misalign. Proper conveyor investment reduces daily labor costs. I have seen belts last five years with good scrapers and only one year without them.

Environmental laws are very strict in 2026. Dusty plants face heavy fines. Investors must buy dust suppression systems. Water spray systems are the cheapest option. Dry dust collectors with bags are more effective. A bag-house filter for a large plant costs $30,000 to $70,000. It removes 99% of fine dust. Many areas require a closed factory. This means the entire line is inside a building. I help my clients choose the right system to meet local laws without wasting money.

A steel building for a line costs $50,000 to $150,000. Noise barriers are necessary near towns. These Mining environmental protection equipment investment costs are high. They ensure the plant can run for many years. Legal trouble from pollution can close a plant permanently. Water recycling is a new trend for 2026. Sand washing plants must reuse their water. This requires settlement ponds or filter presses. I believe recycling water is the only way to operate in dry regions.

A filter press turns mud into dry cakes. This saves water and space. It removes the need for large tailing dams. Tailing dams are risky and expensive to build. Noise control includes silencers on the blowers. It also includes rubber liners in the chutes. These liners reduce the sound of rocks hitting metal. Green mining is no longer optional. It is a requirement for getting a bank loan. Modern investors prioritize these systems from the start. I can help you design a “zero-dust” plant that satisfies even the strictest inspectors.

Shipping heavy machines is a complex task. Operators pay for flatbed trucks or containers. A full plant needs 10 to 15 large trucks. Extra-wide machines need special permits. Transport costs reach $10,000 to $30,000. Port fees apply if importing machines. Once machines arrive, a large crane is necessary. A 50-ton crane is usually the minimum size. Crane rental is charged by the day. I recommend having all foundations ready before the trucks arrive. This saves money on crane rental days.

Installation requires a team of expert welders. It takes 30 to 60 days to test a full line. The Installation and commissioning fee for crushing line covers this labor. Testing safety systems is the final step before production. Local labor for installation is often cheaper. However, a factory supervisor is necessary. The supervisor ensures machines are aligned correctly. I send my best engineers to supervise every project. This prevents expensive mistakes during the first run.

Misalignment causes vibration and early failure. Tools for installation include heavy-duty welders and torque wrenches. Large bolts must be tightened to exact standards. The installation team also builds the chutes between machines. These chutes must be lined with wear-resistant steel. 2026 safety rules require a site safety officer during installation. They ensure all workers use harnesses and helmets. Insurance for the installation period is also a cost. It protects against accidents during heavy lifting. Total installation costs often reach 15% of equipment price. I have seen plants that were built in 30 days because the team was well-organized.

The stone type determines your long-term profit. Hard rocks like granite contain silica. Silica eats through metal very fast. Granite jaw liners might last two months. Limestone liners might last a year. The Maintenance cost of crusher wear parts for granite is much higher. Operators calculate cost per ton for parts. For limestone, this is $0.10 per ton. For granite, it is $0.50 per ton. I always ask for a rock sample before suggesting a crusher.

This difference affects the selling price of the stone. High-manganese steel or ceramic inserts extend part life. These parts cost more but reduce downtime. Choosing the alloy based on rock tests is essential. Downtime is the most expensive part of maintenance. When a machine stops for a liner change, the whole line stops. High-quality parts reduce the number of stops per year. I recommend buying parts in bulk to save on shipping.

2026 technology includes wear-monitoring sensors. These sensors tell the operator exactly how much metal is left. This prevents the liner from wearing through and damaging the frame. Repairing a damaged frame costs ten times more than a new liner. Keeping a stock of liners at the site is mandatory. Waiting for a shipment from the factory kills production. I recommend a “maintenance schedule” based on rock hardness. This allows for planned stops during low-demand periods. I have seen plants save $50,000 a year just by changing liners on a schedule.

Operating a plant requires monthly cash. Electricity is the largest expense. A 1000kW plant has a bill of $10,000 to $20,000. Labor costs depend on the region. A team of 5 to 10 people is standard. This includes a manager, operators, and guards. Maintenance and lubrication are also monthly costs. Grease and hydraulic oil must be bought in bulk. Regular maintenance prevents expensive breakdowns. I suggest using an automated lubrication system to save on labor.

Loader and excavator costs are significant. These machines use diesel to move stone. The total Aggregate production cost analysis must include these. Monthly operating expenses can be $30,000 to $60,000. Working capital must cover these before customers pay. Diesel prices in 2026 are volatile. Many plants now use electric loaders to save money. I can help you calculate the exact cost per ton for your specific site.

Spare parts use is not the same every month. One month might be low, the next might require a full set of liners. Averaging these costs over a year is the best way to budget. Insurance for workers and the plant is also a monthly fee. Taxes and royalties to the government are usually paid per ton sold. Marketing and sales costs help find new customers. A good manager tracks all these in a daily log. This allows the owner to see the exact profit per ton. I have seen owners make better decisions once they saw their daily cost data.

Technology is changing how we invest in mining. Automated systems monitor liner wear. They alert the manager on a phone when it is time to order. This saves money on inventory. Many 2026 plants use solar power to reduce electricity bills. Solar can cover 20% of the day-time energy need. Remote monitoring allows owners to see production from anywhere. I use these tools to help my clients run their plants more efficiently.

Market data shows that sustainable mining is now a requirement. Banks prefer to lend to plants with water recycling and dust control. Small-scale miners are moving toward modular fixed plants. These offer the quality of a stationary plant with the flexibility of a mobile one. I am seeing more interest in “hybrid” plants that use both solar and grid power.

Question 1: Why choose stationary over mobile in 2026?

Stationary plants are cheaper to maintain over five years. They offer more space for large screens and multiple products. They use grid power which is cheaper than diesel fuel. I always recommend stationary plants for projects that will last more than three years.

Question 2: How much is the concrete foundation for a large jaw?

For a PE900x1200 jaw crusher, materials and labor cost about $10,000. This varies by local rebar and cement prices. It is a one-time cost that provides 20 years of stability. I provide the blueprints for this foundation at no extra cost.

Question 3: Should I buy a used transformer?

No. Used transformers often have internal leaks. A failure will stop the entire plant. A new transformer has a warranty and higher efficiency. I have seen many people lose a month of production because of a cheap, old transformer.

Question 4: What is the most common hidden cost?

The most common hidden cost is electrical wiring. Many people forget the cost of armored cables from the transformer to the control room. These can cost $100 per meter. I always include a detailed wiring plan in my quotes.

Question 5: How long to get the first ton of stone?

Expect 6 months. This includes 2 months for factory production, 1 month for shipping, and 3 months for site work and installation. I work hard to speed up the manufacturing process for my clients.

Building a stationary crushing plant is a major project. You must look beyond the machine price. Plan for civil engineering, power, and permits. Total investment ranges from $200,000 to over $1,500,000. Focus on quality core machines to keep daily costs low. Always keep 10% of the budget as a reserve for emergencies. Manage wear parts carefully based on rock hardness. A well-planned plant is a profitable asset for many years. I want to help you build a plant that makes money from the first day.

I suggest a site visit before you finalize the design. Check the soil strength and the distance to the power grid. Hire a professional engineer for the foundation drawings. This prevents the machine from sinking or vibrating. Choose a manufacturer who offers full installation support. This ensures your line starts correctly on day one. I am always available to answer your technical questions.

We manufacture Mining Equipment and mineral processing machinery. ZONEDING has served global clients since 2004. Our products are in over 120 countries. We offer Jaw Crushers, Cone Crushers, and full production lines. Factory-direct sales provide competitive prices for B2B buyers. Our engineers design layouts to maximize your return. We provide full service from design to installation and training. I take pride in the success of every plant we build.

Contact us for a 2026 project consultation and detailed budget.

It's easy to mistake pyrite for gold. This guide shows you a simple streak test and other quick checks anyone can perform to identify fool's gold.

View detailsGet an understanding of what a ball mill is, its fundamental components, and the detailed mechanism behind its efficient grinding process for various materials.

View detailsLearn exactly how silver mining works with our step-by-step guide. We break down the complete process, from ore exploration and mining to final refining.

View detailsThe perfect solution for gold mining. Our portable hard rock crushers are engineered to process gold-bearing ore efficiently.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy