Gold Cyanidation: From Process Types to Plant Construction

3699Your ultimate guide to gold cyanidation. Explore CIL/CIP types, detailed processes, and the complete steps for successful plant construction and optimization.

View detailsSearch the whole station Crushing Equipment

Efficiency in ore processing stems from the strategic balance between crushing, drying, and grinding stages. Core equipment costs typically account for a significant portion of the total investment. Achieving the target fineness with minimal energy consumption remains the primary objective. This analysis explores how the combination of ball mills, rod mills, and dryers creates a seamless production flow. Technical data suggests that correct equipment selection prevents operational bottlenecks and reduces long-term maintenance expenses. Adhering to these standards ensures stable production in large-scale mining operations.

Raw material moisture acts as a primary constraint in mineral processing efficiency. Excessive water content causes ore to become sticky and difficult to transport. Materials with moisture levels exceeding 5% often lead to clogging in conveyors and feeders. Sticky ore also adheres to the internal surfaces of grinding machines. This accumulation forms a cushion that prevents grinding media from effectively striking the ore. Data shows that mills can lose up to 30% of their rated capacity when processing damp materials. Utilizing an efficient Rotary Dryer is mandatory for projects involving dry grinding.

Water alters the internal dynamics of the grinding process. In dry grinding systems, moisture converts dust into a thick paste that clings to the liners. This paste increases the rotational weight of the drum without contributing to material reduction. Energy is consumed to rotate the equipment, but output remains stagnant. Integrating a dryer ensures the ore remains a free-flowing powder. Direct contact between the grinding media and the dry rock results in faster breakage. This is particularly critical for industrial minerals like lime or cement.

Wet processing plants operate under different logic. Operations such as a Gold Processing Plant generally do not require pre-grinding drying. Water is added during the grinding stage as a transport medium. However, for glass sand or chemical-grade powders, moisture must remain below 1%. A high-capacity dryer ensures consistent production regardless of seasonal weather changes. Reliable drying equipment serves as a safeguard for annual production targets. It eliminates the risk of downtime during rainy periods.

| Moisture Content | Effect on Grinding | Required Action | Practical Benefit |

|---|---|---|---|

| Below 3% | Minimal friction | Direct feed | Reduced initial cost |

| 3% to 8% | Visible sticking | Single Cylinder Rotary Dryer | Stable material flow |

| Above 8% | Severe blockage | Three-Cylinder Rotary Dryer | High thermal efficiency |

Rod mills utilize line contact for material reduction rather than point contact. In a ball mill, steel spheres strike the rock at single points of impact. This mechanism frequently shatters the rock into excessively fine particles. This phenomenon is known as over-grinding. A Rod Mill employs long steel rods that remain parallel during rotation. These rods function like a series of rollers. The rods trap larger rocks between them and crush them preferentially. Smaller particles occupy the gaps and receive less direct force.

This selective grinding mechanism is the reason for superior particle size distribution in manufactured sand. Concrete production requires specific aggregate size ranges to ensure structural strength. Excessive fine dust increases the demand for cement and raises costs. Rod mills produce a product with a very narrow size range. Research indicates that rod mills generate approximately 15% fewer unwanted fines compared to ball mills. This result yields a higher percentage of marketable products and less waste material.

The rods also prevent coarse particles from exiting the system prematurely. Since the rods span the entire length of the drum, no large rock escapes without being crushed. Ball mills occasionally allow flat or elongated rocks to slip between the spheres. This makes the rod mill the industry standard for the sand and aggregate sectors. The resulting material closely mimics the properties of natural river sand. For projects requiring -5mm or -3mm aggregates, the rod mill remains the most effective tool.

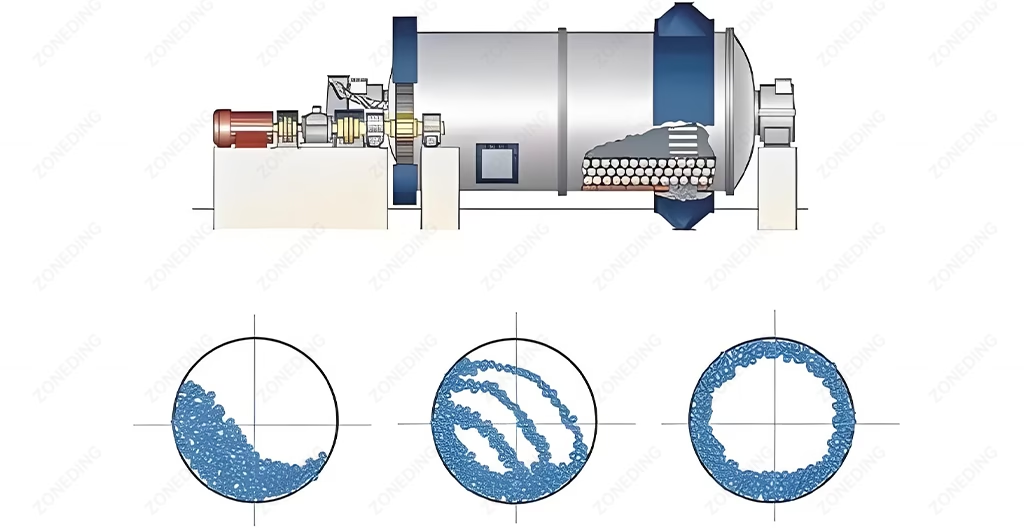

Selecting the appropriate ball size distribution is a process known as ball charge grading. A common error is the exclusive use of large-diameter balls. While large balls break coarse rocks, they provide insufficient surface area for fine grinding. Grinding efficiency depends on a balance of impact force and total surface area. Large balls (90mm to 100mm) handle initial breakage. Small balls (40mm to 60mm) provide the necessary contacts to grind particles into fine powder. If the gaps between media are too large, fine particles remain unground.

Multi-stage grading is recommended for Ball Mills processing hard metallic ores. Iron or copper ores typically require a specific mixture. A standard initial load includes 30% large balls, 40% medium balls, and 30% small balls. This ensures that every particle size within the mill undergoes reduction. As operations continue, the media wears down. Large balls naturally diminish in size to become medium balls. Consequently, routine maintenance usually only involves adding the largest ball size to the system.

Harder ores demand higher impact energy. Tougher rock types may require an increase in the percentage of large-diameter media. However, excessive large balls accelerate the wear rate of internal liners. Periodic output testing helps verify the correct ratio. If the discharge contains too many coarse grains, the proportion of large balls should increase. If the fineness is acceptable but the total throughput is low, adding small balls increases the surface area. This balance is vital for an efficient Iron Ore Beneficiation operation.

Elevated ore temperatures from a dryer can degrade grinding mill components. When hot ore enters the mill, heat transfers to the bearing systems. Most large mills utilize specialized lubrication oil or grease. If temperatures exceed 70 degrees Celsius, the lubricant loses its viscosity. Thin oil fails to provide a protective film between metal surfaces. This leads to increased friction, thermal spikes, and bearing failure. Replacing a main bearing results in significant downtime and high costs. Cooling the ore before it enters the grinding stage is a necessary precaution.

Thermal energy also causes the steel liners to expand within the drum. Expansion puts immense stress on the liner bolts. This can lead to bolt breakage or warping of the liners. Once warped, liners no longer sit flush against the mill shell. This allows fine particles to seep behind the liners. This abrasive material will wear through the mill shell in a short period. Protecting the shell from internal wear is a critical maintenance priority. Ignoring feed temperatures can lead to catastrophic equipment failure.

Heat also creates “ball coating” in dry grinding systems. Some minerals become slightly plastic or sticky when heated. These materials adhere to the surface of the grinding balls. Once coated, the balls lose their abrasive effectiveness. Production rates drop significantly even if the motor speed remains constant. Installing a Rotary Cooler between the dryer and the mill is a proven solution. This addition protects the investment and maintains high production levels.

The combination of a rod mill and a ball mill represents the most energy-efficient grinding configuration. In a two-stage system, the rod mill performs coarse grinding while the ball mill handles the final reduction. This division of labor is more efficient than utilizing a single large ball mill. The rod mill reduces 20mm ore to approximately 2mm. The ball mill then processes the 2mm feed into fine powder. This strategy can reduce total electricity consumption by 15% to 20%.

Energy savings occur because each machine operates within its optimal size range. Ball mills are inefficient at breaking 20mm rocks as the media often bounces off large stones. Rod mills are specifically designed for this size range. By providing a uniform 2mm feed to the ball mill, the secondary stage can use smaller media. Smaller media offer more surface area for grinding. This leads to faster throughput and less power used per ton of product. For a large Beneficiation Equipment plant, this represents substantial monthly savings.

A common configuration includes an open-circuit rod mill followed by a closed-circuit ball mill. The rod mill requires no classifier and simply passes the material through. The ball mill operates in conjunction with a Spiral Classifier or hydrocyclone. This ensures that only the target fineness exits the system. This combination is the global standard for copper and iron mining. It provides the highest output for every kilowatt of power.

Dryer throughput must exceed the grinding mill capacity by at least 10%. A slow drying stage leaves the mill under-fed. This results in energy waste and accelerated wear on the media. Calculating the required capacity involves determining the evaporation rate. Drying one ton of ore with 10% moisture requires significantly more energy than drying one ton with 5% moisture. The calculation must account for the total mass of water to be removed per hour.

Volumetric drying efficiency is a key metric. This defines the amount of water removed per cubic meter of the dryer drum per hour. A standard Single Cylinder Rotary Dryer typically removes 30kg to 40kg of water per cubic meter. If a project requires removing 500kg of water per hour, the dryer must provide at least 15 cubic meters of internal volume. It is standard practice to include a safety margin for unexpected moisture increases during rainy weather.

Air velocity within the drum also affects capacity. High-velocity air can carry fine particles out through the exhaust. Low-velocity air allows moisture to condense inside the drum. A properly sized fan and dust collection system are essential. The diameter and length of the dryer must be tailored to the specific local climate. Equipment that performs in dry regions may underperform in humid environments. Sizing the Drying Equipment for worst-case scenarios ensures continuous operation.

Fragile minerals such as tungsten and tin are susceptible to over-grinding. If these minerals are ground too finely, they become slimes. Most gravity separation equipment cannot recover slimes, resulting in the loss of valuable metal. A Rod Mill provides a protective grinding environment. The parallel rods act as a screen. They focus the energy on larger rocks while allowing smaller particles to remain in the gaps between the rods.

This mechanism is driven by the physical support of the rods. The largest pieces of ore keep the rods separated. Smaller particles sit in the spaces between and avoid further reduction. In contrast, a ball mill allows the media to hit all particles indiscriminately. This makes the rod mill mandatory for ores that rely on gravity separation. It produces a sandy discharge with minimal dust content. Studies show that switching to a rod mill can improve recovery rates for fragile minerals by up to 10%.

A high dilution ratio is recommended for wet grinding of fragile ores. Increased water flow helps wash fine particles out of the mill quickly. The objective is to remove the mineral from the mill as soon as it reaches the target size. Shorter mills are also preferred for these applications. A shorter path through the mill reduces the time the ore is subjected to grinding forces. This strategy maintains the minerals within the optimal size range for collection.

| Grinding Goal | Rod Mill Performance | Ball Mill Performance | Result |

|---|---|---|---|

| Particle Protection | High | Low | Less mineral loss |

| Slime Generation | Minimal | Moderate | Better recovery |

| Product Uniformity | High | Low | Easier sorting |

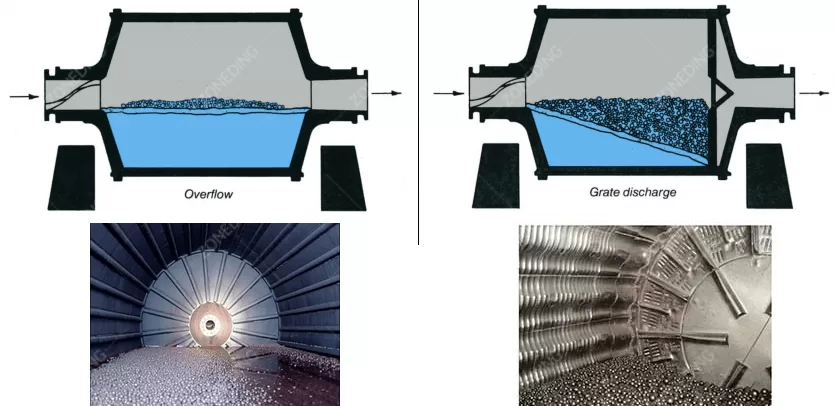

The method of discharge dictates how a mill handles dry material flow. An overflow ball mill operates on the principle of passive displacement. Material exits the mill once the level rises above the discharge opening. This is effective for wet grinding as water transports the solids. However, dry powder does not flow as easily as a slurry. In a dry overflow mill, the material stays inside for too long. This leads to excessive grinding and the creation of ultra-fine dust. Overflow mills are rarely used for dry powder production.

A grate discharge ball mill is the preferred choice for dry ore. This design features a steel grate at the discharge end. Behind the grate, lifting vanes scoop the material out of the mill. This creates a forced discharge mechanism. It pulls the dry powder out of the system quickly and prevents over-grinding. For chemical-grade powders or Ore Powder Dryer feed preparation, the grate type is the logical selection.

The internal pulp level also differs between the two types. Grate mills maintain a low material level. This allows the grinding media to hit the ore with maximum force. In an overflow mill, the higher level of material cushions the impact. For hard and dry materials, the high-impact force of the grate mill is more effective. It allows for higher throughput per hour using the same equipment footprint. Replacing overflow units with grate discharge units typically improves performance in dry plants.

A combined processing line requires a dust system that handles both heat and humidity. Dryers produce hot, moist air. Mills produce dry, fine dust. Mixing these two streams prematurely results in mud formation inside the ductwork. This mud clogs filters and halts production. Professional designs use separate collection points for each stage. The dryer should utilize a Cyclone to remove heavy particles while the air remains at a high temperature.

A bag-house filter is the most effective solution for final air cleaning. The filter bags should be treated with water-resistant and oil-resistant coatings. This prevents the moisture from the dryer from soaking into the fabric. If the fabric becomes saturated, dust adheres to it permanently. This is known as blinding. Insulating the dust pipes is also recommended. Insulation prevents the air temperature from dropping. If the air cools, water condenses and creates clogs in the system.

The exhaust fan must provide sufficient negative pressure to pull dust from all machines. Monitoring the pressure across the filters is standard practice. If the pressure increases, the system triggers an air pulse to clean the bags. A high-quality dust system also recovers valuable fine product. The dust collected is often the highest grade of the final product. Recovering this material can cover the electricity costs of the fan.

Wear components represent the largest recurring expense in grinding operations. For ball mills, high-manganese steel is the standard material. It is tough and hardens during impact. However, for abrasive rocks like quartz, manganese steel may wear too quickly. Chrome-alloy steel is a better choice for high-abrasion environments. While the initial price is higher, chrome alloys can last twice as long. Reducing the frequency of liner changes saves on both labor and lost production time.

In a Rod Mill, the quality of the rods is the most important factor. Heat-treated alloy steel rods are required. Low-quality rods tend to bend or break under stress. A bent rod creates a tangle within the mill that is difficult to remove. This type of failure can stop production for several days. Investing in high-quality rods prevents these catastrophic maintenance events. The cost of one rod-related shutdown exceeds the savings from cheaper alternatives.

Rubber liners are an alternative for wet grinding applications. Rubber is significantly lighter than steel, which reduces power consumption. It also performs well with small grinding media and reduces operating noise. However, rubber cannot handle feed sizes larger than 10mm. Coarse rocks will tear the rubber surface. A hybrid approach is often used in two-stage plants. Steel liners are installed in the primary mill, while rubber liners are used for the fine-grinding secondary mill. This optimizes both cost and performance.

The fuel used in a dryer can alter the chemical composition of the ore. Coal combustion produces ash and sulfur that can contaminate the mineral. This is a significant issue for high-purity minerals like kaolin or white quartz. Contamination reduces the market value of the final product. For sensitive minerals, natural gas or indirect heating is recommended. In an indirect dryer, the flame remains separate from the ore, and heat is transferred through a metal wall.

Natural gas is the cleanest fuel for direct-fired dryers. It produces virtually no ash. For the production of glass-grade sand, gas is the industry standard. Biomass fuels are also an option in 2026. While cheaper than gas, biomass does produce some ash. If the mineral is destined for a smelting furnace, such as Copper Processing Plant feed, coal is usually acceptable. The smelting process will remove minor impurities.

Temperature control is also essential. Certain minerals undergo chemical changes if exposed to excessive heat. Gypsum, for example, will change its crystal structure if the dryer temperature is too high. Automated burners should be linked to the material discharge temperature. This ensures a consistent product and prevents “burning” the ore. The choice of heat source is directly related to the final product’s quality and price.

The most accurate evaluation of a project is the total cost per ton over a five-year period. The purchase price of the machinery is only one part of the equation. Low-cost equipment often consumes more electricity and requires more frequent repairs. Over several years, the cost of excess power can exceed the initial savings. Evaluating the ROI involves looking at energy efficiency, liner lifespan, and recovery rates. A High efficiency mineral grinding process pays for itself through reduced operating costs.

In 2026, automation also influences ROI. Systems with integrated sensors require fewer operators and reduce payroll expenses. Uptime is another critical metric. High-quality mills from ZONEDING typically operate for 7,500 hours per year. Lower-quality alternatives may only reach 6,000 hours due to frequent maintenance. The loss of 1,500 hours of production has a massive financial impact. Professional ROI models show that well-designed lines typically recover their investment in 12 to 18 months.

The salvage value of the equipment should also be considered. Heavy machinery from established brands maintains its value on the secondary market. If a project requires an upgrade in ten years, the used machines can be sold for a significant amount. Low-quality equipment often has only scrap value. Focus on the Total Cost of Ownership ensures long-term profitability. Building a processing line is an investment in a financial asset.

Question 1: Can a ball mill produce high-quality sand?

Yes, but a ball mill generates more waste dust than a rod mill. To use a ball mill for sand, a high-efficiency Sand Washing Machine is required to remove excess fines.

Question 2: What is the typical lifespan of ball mill liners?

Lifespan depends on rock hardness. For limestone, liners can last 12 to 18 months. For iron ore or granite, they may only last 4 to 6 months. Chrome alloy liners can extend this duration.

Question 3: Is a three-drum dryer better for all minerals?

Three-drum dryers are highly efficient for small materials like sand. However, for large or sticky rocks, a single-drum dryer is easier to maintain and less likely to clog.

Question 4: What is the most effective way to feed a mill?

A Vibrating Feeder with a frequency inverter is the best choice. This provides a steady and controllable flow of material, which is the key to a stable grinding process.

Question 5: Why is a thickener used after wet grinding?

A High Efficiency Concentrator (thickener) removes excess water from the slurry. This concentrates the solids before they enter the flotation or leaching stages.

ZONEDING MACHINE is a manufacturer of Beneficiation Equipment and mineral processing machinery. Since 2004, the company has provided industrial solutions to clients in over 120 countries. Specialized products include Ball Mills, Rod Mills, and Rotary Dryers. A team of 15 professional engineers ensures that every project meets high efficiency standards. Direct factory sales provide competitive pricing for B2B global buyers. The focus remains on building profitable and sustainable mining operations.

Contact ZONEDING for technical consultations and detailed equipment quotations.

Your ultimate guide to gold cyanidation. Explore CIL/CIP types, detailed processes, and the complete steps for successful plant construction and optimization.

View detailsTungsten is a strategic metal characterized by its extreme density and brittleness, often described in mineral processing as "heavy as iron but fragile as glass." The successful extraction of this metal depends entirely on correctly identifying t...

View detailsSeparating gold and silver from mixed ore requires a specific chemical and mechanical approach. Extracting gold from silver-gold ore involves multiple stages like crushing, grinding, and leaching. Modern mining plants use the Merrill-Crowe system...

View detailsYour ultimate guide to choosing a hard rock gold processing solution. Learn about key factors like ore type, capacity, and processing methods (CIL, flotation) to make the right choice.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy