Search the whole station Crushing Equipment

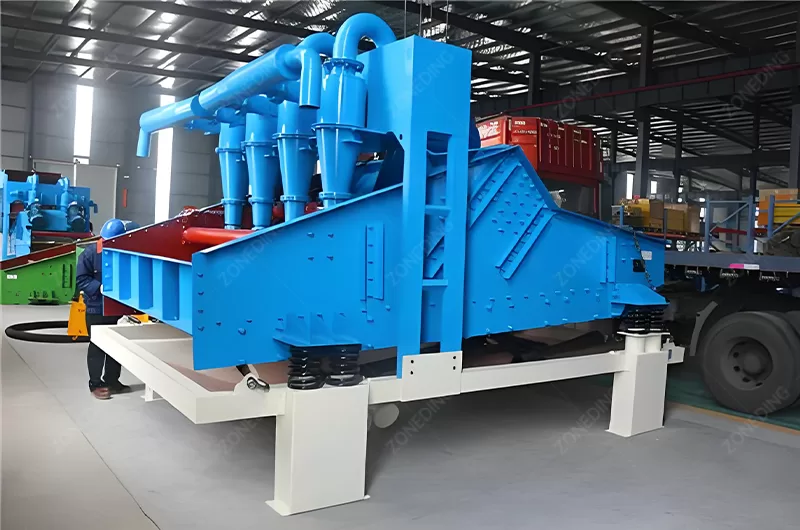

Application Areas: Sand and gravel production lines, dehydration stage in ceramic raw material processing systems, tailings recovery and treatment in concentrators, quartz sand processing systems, sand and gravel processing systems for hydropower stations, etc.

ZONEDING MACHINE. ZONEDING makes equipment for processing minerals. Many sand washing plants and mines lose a lot of fine sand. This fine sand is valuable. Losing it means you lose profit. It also creates environmental problems. The fine sand ends up in wastewater or tailing ponds. This can cause pollution. It makes getting environmental permits harder. A Fine Sand Recovery Machine is a solution.

A Fine Sand Recovery Machine is a specialized piece of equipment. Its main job is to capture the fine sand that traditional processes lose. Think of it as a system designed specifically to deal with the water carrying those tiny valuable particles. People call it by different names. Some call it a tailing sand recycling machine. Some say fine sand extraction machine. Others use fine sand collection machine or sediment separator. It is also known as a mud separator or a sand and water mixture processing system. We also call it a Fine sand recovery device or a Fine Sand Recycling Machine. Its core function is to take the muddy water (slurry) from your washing process. It pulls out the valuable fine sand from this slurry. It then dewaters this sand. It returns relatively clean water to your plant.

This machine was developed because traditional Sand Washing Machines could not solve the problem of fine sand loss. They were good at washing, but not good at catching the fines below a certain size. This new machine is designed to specifically overcome that difficulty. It solves the challenge of controlling and recovering fine sand during the washing and dewatering stages. It effectively reclaims the fine sand that would otherwise be sent to waste. It is like a special net designed to catch very small fish. It takes the dirty water stream and extracts the valuable part. This turns a waste stream into a valuable product stream. It is a highly effective way to recover material and clean water at the same time. It can also remove dirty soil from the sand product stream, helping to wash sand clean. This is why some call it a Gravel Cleaning Machine.

This machine is built to handle the specific challenge of recovering fine particles suspended in water. It turns a problem stream into a resource.

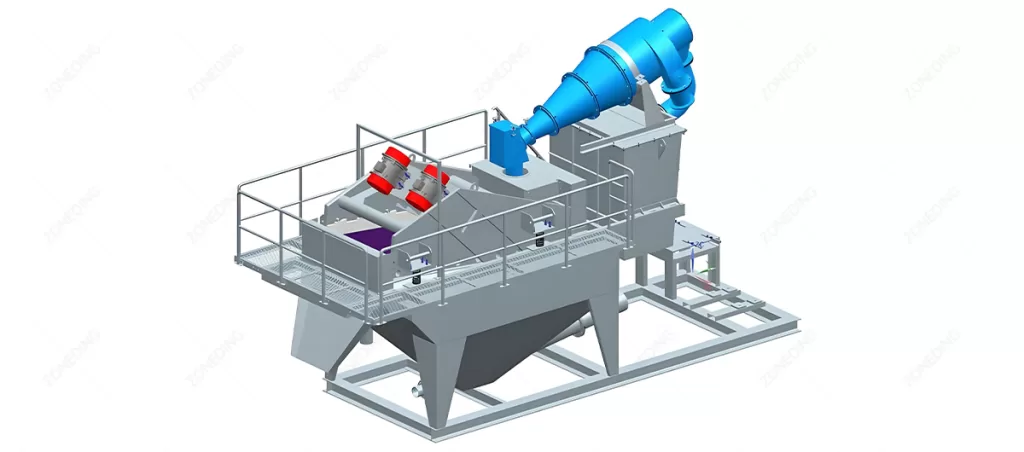

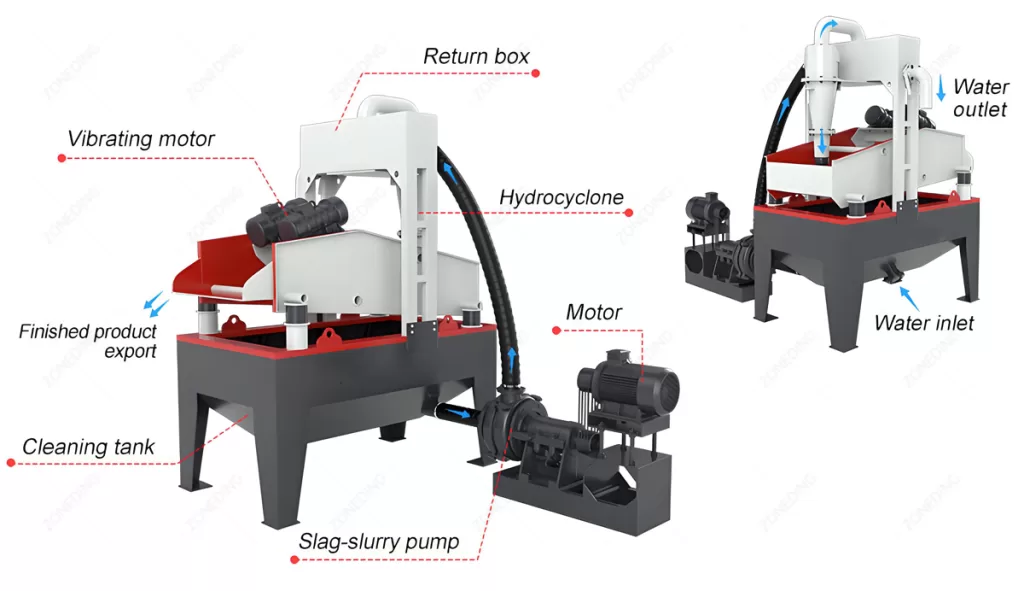

he idea behind turning “mud” into “treasure” with this machine is smart design. It uses a few steps and key parts to separate the fine sand from the water. The process starts with the muddy water that comes from your Sand Washing Machine or other washing process. This slurry contains water, very fine sand, silt, and clay. This slurry flows into a collection tank, also called a sump. There is a pump in this tank. It is usually a slurry pump. This pump is very important. It takes the slurry from the sump and pumps it under pressure to the next part.

The next part is a Hydrocyclone. This is where the main separation happens. The slurry enters the hydrocyclone at an angle. This makes the slurry spin very fast inside the cyclone. This spinning creates centrifugal force. Heavy particles (like fine sand) are thrown outwards. They move down the cone and exit through the bottom opening, called the apex. Lighter particles (like silt and clay) and most of the water stay in the center. They move upwards and exit through the top opening, called the overflow. This step separates the fine sand from most of the water and lighter waste. The fine sand that exits the bottom of the hydrocyclone still contains some water. It is a thick slurry. This slurry then goes to a dewatering screen. This is usually a high-frequency vibrating screen. The vibrating action and the screen mesh separate more water from the fine sand. The water goes through the screen. The fine sand stays on top of the screen. The screen vibrates. This moves the dewatered fine sand off the screen. The sand drops down as a pile of valuable, recovered fine sand. The water that goes through the screen and the water from the hydrocyclone overflow can be collected. You can reuse this water in your plant or treat it further. A buffer storage might be used before or after the process to manage flow. The whole system works together to take a watery waste stream and produce dry sand product and cleaner water.

Using a Fine Sand Recovery Machine is good for your wallet and the planet. The most obvious benefit is financial. You recover valuable fine sand. This sand is a saleable product. You were losing it before. Now you sell it. This directly increases your revenue and profit. You also reduce your need to buy new sand. This saves you money on raw materials. It saves you money on transport costs for those materials.

Beyond making more money, this machine helps with big environmental and cost issues. Traditional sand washing creates a lot of fine waste material in water. This muddy water is hard to handle. It often goes to tailing ponds. Tailing ponds take up a lot of space. They need permits. They need maintenance. They can be an environmental risk. They are expensive to build and manage. By recovering the fine sand, you reduce the amount of solids going to your tailing pond. The water that leaves the Fine Sand Recovery Machine is much cleaner. It has far fewer suspended solids. This makes meeting environmental discharge standards easier. Cleaner water means less pollution. It means fewer problems with regulators. It can reduce the size and cost of your tailing pond. It can extend the life of your existing pond. You can also reuse the cleaner water in your plant. This reduces your need for fresh water. Saving water saves you money. It also makes your operation more sustainable. New environmental regulations are becoming stricter. Recovering fine sand helps you stay ahead of these rules. It makes your operation more environmentally friendly. This is good for your reputation too.

Choosing the right Fine Sand Recovery Machine depends on several things. You need a machine that handles your specific material. You need a machine that matches how much material you process. Suppliers offer different models and sizes. These models have different capacities. They handle different types of slurry.

First, look at your material. What is the size distribution of your fine sand? How much fine sand is in your slurry? What is the concentration of solids in the water? Is your material very abrasive? These factors influence the size and type of hydrocyclone you need. They affect the pump size and the screen type. Next, think about your capacity requirement. How many tons of fine sand do you need to recover per hour? How much slurry volume (water and solids) does the machine need to process? Machines are rated by capacity. For example, a model like WS1530 might have a certain processing capacity range. Make sure the machine’s capacity is right for your plant. You do not want a machine that is too small. It cannot handle your flow. You do not want one that is too big. It wastes energy.

Also, consider the desired output moisture. How dry do you need the recovered sand to be? Different dewatering screens achieve different moisture levels. Think about your budget. Different models and sizes have different costs. Consider the long-term operating costs, too. A more expensive machine might be more energy efficient or have more durable parts. This saves money over time. Think about the space you have in your plant. These machines need space for installation and maintenance. We can help you figure out the right size and configuration. We look at your specific material properties and your capacity needs. We recommend a model that fits. New models are often designed to be multi-functional, economical, and have enhanced environmental features, based on user feedback.

| Model | Feeding Size (mm) | Capacity (t/h) | Screen Panel (mm) | Hydrocyclone (mm) | Power (kw) | Overall Size (mm) |

| ZD250 | ≤10 | 20-50 | 900*1800 | 250 | 12.5 | 3100*1300*2700 |

| ZD300 | ≤10 | 40-80 | 900*1800 | 300 | 16.5 | 3100*1300*2700 |

| ZD350 | ≤10 | 60-100 | 900*1800 | 350 | 20 | 3100*1300*2700 |

| ZD550 | ≤10 | 40-100 | 1200*2400 | 250*2 | 26.4 | 3600*1600*2800 |

| ZD650 | ≤10 | 80-160 | 1200*2400 | 300*2 | 34.4 | 3600*1600*2800 |

| ZD750 | ≤10 | 120-200 | 1200*2400 | 350*2 | 41.4 | 3600*1600*2800 |

| ZD900 | ≤10 | 120-250 | 1500*3000 | 300*3 | 51 | 4600*1900*2600 |

| ZD1050 | ≤10 | 150-300 | 1500*3000 | 350*3 | 61.5 | 4600*1900*2600 |

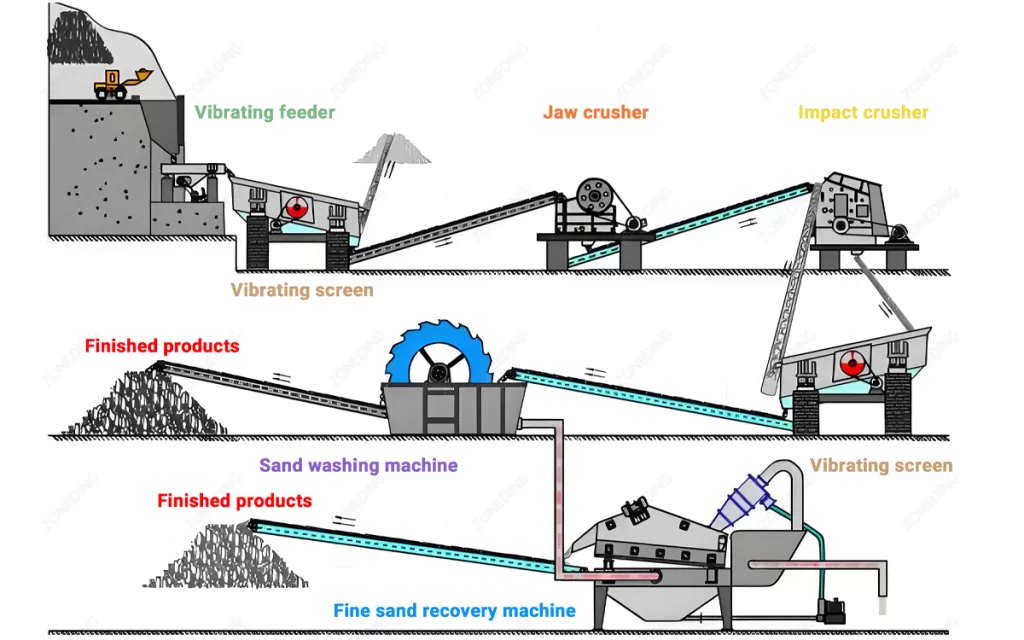

Putting a Fine Sand Recovery Machine into your current plant needs careful planning. You want it to work smoothly with your existing equipment. It should improve your process, not complicate it. The most common place to put the machine is after your Sand Washing Machine. The overflow water from the washer goes directly to the recovery machine’s sump. This is where the lost fine sand is. Another place could be to process the overflow from another separation step, like a Spiral Classifier. It can also be placed to treat the slurry stream before it goes to the tailing pond.

You need to think about the connections. You need pipes to carry the slurry from your washer to the recovery machine’s sump. You need a pump to move the slurry from the sump to the hydrocyclone. You need pipes or conveyors to move the recovered fine sand to where you want it (stockpile, storage). You need pipes or channels to take the cleaner water away. Elevation is important. The machine should be placed so liquids flow correctly. Power supply is needed for the pump and the vibrating screen. You need an electrical control box. A buffer storage tank before the sump can help handle surges in flow from your washing process. This makes the feed to the recovery machine more steady. A steady feed helps the hydrocyclone work best. You also need to consider maintenance access. The pump, screen, and hydrocyclone liner are wear parts. You need space to check and change them.

Talk to your supplier about the best way to integrate the system. They can help you design the layout and connections. A good design ensures the machine works effectively and safely within your existing plant structure. We offer complete systems. We can help you integrate the machine with your Jaw Crusher, Vibrating Feeder, Vibrating Screen, Ball Mill, or other equipment you have.

Running a Fine Sand Recovery Machine has costs. These costs are usually lower than the value you get from the recovered sand. The main running costs are power consumption, water usage, and wear parts replacement. The slurry pump and the vibrating screen motor use electricity. The amount of power used depends on the machine size and how much material you process. Compared to the energy used for primary crushing with a Jaw Crusher or grinding with a Ball Mill, the power for a recovery machine is often moderate for the value it adds.

Water usage is mainly for the fluidization water (if used in the hydrocyclone) and for washing down areas. But the system also saves water by allowing reuse of the cleaner overflow water. So, net water cost might decrease. The biggest variable cost is wear parts. Parts that touch the fast-moving slurry will wear out over time. Common wear parts include the pump impeller and casing, the hydrocyclone liner (especially at the apex and vortex finder), and the vibrating screen mesh. The life of these parts depends on your material. Abrasive materials (like granite or basalt sand) cause parts to wear faster than less abrasive materials (like river sand). How you operate the machine also affects wear. Running it correctly, with the right slurry concentration and flow, extends part life.

Replacing wear parts is part of the cost of ownership. The replacement frequency varies a lot. It can be every few weeks or several months. This depends on your material’s abrasiveness, the operating hours, and the quality of the wear parts. A good supplier uses durable materials for these parts. They can also advise you on expected wear life based on your material. Regular maintenance, like checking wear parts and keeping the machine clean, is important. It helps prevent unexpected breakdowns. It keeps the machine running efficiently. It extends the life of major components. While there are running costs, the value of the recovered fine sand often outweighs these costs significantly.

Choosing the right supplier is critical for buying a Fine Sand Recovery Machine. You need a partner who knows this equipment and its applications. They should have the technical ability to help you. They should have proven experience. Do not just look for the cheapest machine. Look for quality and support.

Check their experience in the mineral processing industry. How long have they been making equipment? We have been making mineral processing equipment since 2004. This means we have a lot of experience. Ask about their technical team. Do they have engineers who specialize in gravity separation and material processing? Our factory has 15 professional engineers. They design our machines. They understand how to process different materials. Visit their factory if possible. See their manufacturing equipment. Do they use modern tools? This tells you about the quality of their machines. Our factory is 8000 square meters. We have good equipment. Ask if they have test facilities. Can you send them a sample of your material? Good suppliers test your material. They show you how their machine performs with your specific sand. This confirms it will work before you buy.

Ask for references. Can they give you contact details of other customers who use their Fine Sand Recovery Machine? Talk to those customers. Ask them about the machine’s performance. Ask about the supplier’s after-sales service. How good is their installation help? Do they provide training? Are spare parts easy to get? We have exported to over 120 countries. This shows we have global experience and many successful cases. A supplier who can provide a complete solution, from designing the system based on your needs to helping you install it and training your staff, is the best choice. We can help you integrate the recovery machine with your Mobile Crusher or other equipment.

Q 1: How dry is the sand recovered by this machine?

A: The dewatering screen can typically reduce the water content of the recovered sand to 10-15%, depending on the particle size distribution and screen type. It is much drier than the original slurry.

Q 2: Can it recover very fine silt and clay?

A: No, the hydrocyclone is set up to separate fine sand. Silt and clay are much finer and lighter. They go out with the hydrocyclone overflow and the screen water. The machine specifically targets valuable fine sand.

Q 3: Is this machine difficult to operate?

A: No, the main operation is starting the pump and vibrating screen. Adjustments like fluidization water flow or screen angle are set during commissioning. Daily operation is relatively simple, but regular checks and maintenance are needed.

Jaw Crusher Applicable Material:Quartz, granite, basalt, limestone, river stone, marble, shale, iron ore, copper ore, gold ore etc. A Jaw crusher is mainly used for medium-sized crushing of various ores and …

Cone crusher is usually used as secondary or tertiary crushing stage. It is characterized by robust structure, excellent productivity and simple operation. Cone crusher is ideal for crushing different stone and ro…

Sand making machine is suitable for soft or medium hard and very hard ore materials with hardness not higher than 320 Pa. Also. It has the characteristics of stable and reliable work, easy maintenance, and a high sand production rate. The…

Impact crusher excel in primary crushing of rock. Stationary and mobile plants are available. Replacement of wearing parts is simple due to the hydraulic folding of the housing components. A variety of models are available | Get the fre…

The vibrating feeder (vibratory feeder) is suitable for bulk and granular materials such as limestone, calcite, dolomite, barite, talc, gypsum. And also quartz stone, river pebble, granite, basalt, construction waste, iron ore, coal, slag, …

Sand washing machine is an important equipment for artificial sand and natural sand washing operation. It can wash away the trace stone powder and impurities in sand and gravel to improve the quality of sand. A&…

Vibrating Screen characterizes simple structure, high efficiency, reliable use and convenient installation, and can perform multi-special segmentation screening of loose materials. It is main equipment to separate soild materials, it …

Roller crusher is also known as roll crusher, which relies on the high-speed rotation of roll wheel to crush materials. The commonly used roll crusher types include double roller crusher, toothed roller crusher, four roller crusher, etc. …

Fine crusher is also called tertiary crusher, which adopts the principle of “stone hit stone” to crush materials. It upgrades the traditional three crushing stages to the two crushing stages. A Fine Crusher&n…

Compound crusher is the newly developed equipment by combining sand making machine and the crushing principle of impact crusher. A compound crusher, also called vertical compound sand maker, is a double-rotor prim…

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy