Search the whole station Crushing Equipment

Compound crusher is the newly developed equipment by combining sand making machine and the crushing principle of impact crusher.

A compound crusher, also called vertical compound sand maker, is a double-rotor primary impact crusher. The compound crusher is an ideal machine for crushing high-moisture and viscous materials, commonly used in small-scale crushing and sand production lines.

A Compound Crusher is a type of crusher that combines multiple crushing mechanisms within a single machine. It typically uses a combination of impact and grinding forces to reduce materials to a fine size. Unlike simple crushers, it can achieve a high reduction ratio, meaning it can take relatively large feed sizes and produce very small output sizes in one step.

A compound crusher offers several key advantages that make it a valuable asset for certain applications:

Compound crusher combines the advantages of impact crusher and hammer crusher, showing multiple highlights. Its features include:

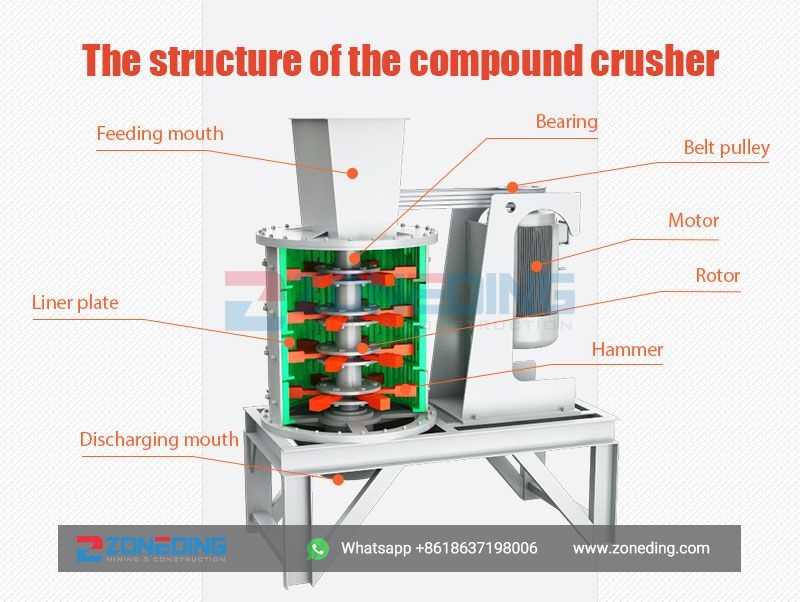

The main components of a compound crusher include:

The vertical compound crusher is mainly composed of the crushing system (rotor, bearing, liner, hammer), transmission system (motor, pulley), in-and-out mouths, and other parts. Among them, the crushing system is the easy-wearing component, which is mainly introduced for you.

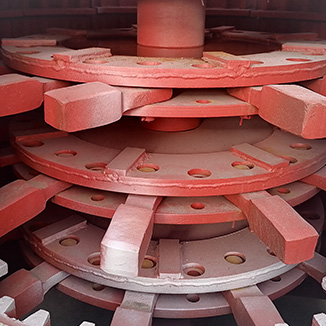

The flat hammer is a vulnerable part of the crusher, installed on the rotor. They break the material by striking it repeatedly.

The hammer head is made of wear-resistant alloy steel or bimetal thermal compound material and the weight is generally between 9-36 kg.

The rotor is a key part installed vertically in the crusher and is made of solid cast steel. Itscircumference is equipped with hammers with adjustable clearance, responsible for high-speed rotation.

The rotor has a special structure that won’t be worn once crushed. The speed and rotation direction of the rotor affect the crushing efficiency.

The liner plate refers to the wear-resistant plate inside the crushing chamber, which plays the role of grinding materials and protecting the cylinder from wear.

The special casting and heat treatment process makes the liner have good impact resistance.

The bearing assembly supports the rotation of the rotor and is critical to the smooth operation of the crusher.

Generally, double-row radial spherical roller bearings are selected, which have strong bearing capacity and good self-aligning performance.

Compound Crusher has a wide range of applications and is commonly used for crushing medium-hard materials in middle or small-sized plants. Here are some specific applications:

Coal, limestone, granite, cobble, dolomite, bluestone, iron ore, coal gangue, activated carbon, quartz, basalt, slag, etc.

Application of Compound Crusher

Compound crushers are best suited for materials that are moderately hard and not excessively abrasive. They can effectively handle a variety of rocks and ores, including:

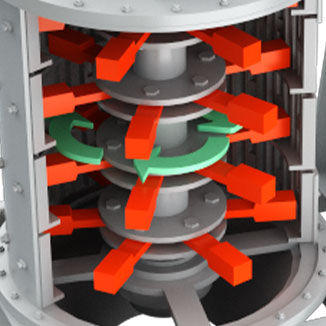

The material in the upper part of the machine perpendicular drops into the high speed rotating impeller,and under the high speed centrifugal force, it produces high speed impact and comminution with the other part of the material which distributes in the shape of umbrella around the impeller vertical composite crusher. The impeller and the housing will be crushed by swirl impact and friction between the impeller and the housing for many times, which will be discharged directly from the bottom, forming a closed circuit multiple cycles, and controlled by the screening equipment to achieve the required product size.

The Vertical Compound Crusher works using a combination of impact and grinding forces. Here’s a step-by-step breakdown:

The choice depends on your specific needs and material characteristics:

If you need very fine material with a good shape and are working with moderately hard rock, the compound crusher is the best choice.

ZONEDING compound crushers are designed with several features to ensure high performance and reliability:

ZONEDING’s Compound Crusher for Wet Material ensures consistent performance in challenging conditions.

The price of a compound crusher can vary widely depending on its size, capacity, and features. Small to medium-sized crushers can range from $10,000 to $50,000, while larger, high-capacity crushers can cost upwards of $100,000. Contact ZONEDING for a customized quote based on your specific requirements.

The production capacity of a compound crusher depends on several factors:

| Specification | Processing Capacity(t/h) | Motor Power(kw) |

| 800 | 5-15 | 4p 30kw |

| 1000 | 10-30 | 4p 55kw |

| 1250 | 20-60 | 6p 90kw |

| 1500 | 30-80 | 8p 110kw |

| 1750 | 40-100 | 8p 160kw |

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Jaw Crusher Applicable Material:Quartz, granite, basalt, limestone, river stone, marble, shale, iron ore, copper ore, gold ore etc. A Jaw crusher is mainly used for medium-sized crushing of various ores and …

Cone crusher is usually used as secondary or tertiary crushing stage. It is characterized by robust structure, excellent productivity and simple operation. Cone crusher is ideal for crushing different stone and ro…

Sand making machine is suitable for soft or medium hard and very hard ore materials with hardness not higher than 320 Pa. Also. It has the characteristics of stable and reliable work, easy maintenance, and a high sand production rate. The…

Impact crusher excel in primary crushing of rock. Stationary and mobile plants are available. Replacement of wearing parts is simple due to the hydraulic folding of the housing components. A variety of models are available | Get the fre…

The vibrating feeder (vibratory feeder) is suitable for bulk and granular materials such as limestone, calcite, dolomite, barite, talc, gypsum. And also quartz stone, river pebble, granite, basalt, construction waste, iron ore, coal, slag, …

Sand washing machine is an important equipment for artificial sand and natural sand washing operation. It can wash away the trace stone powder and impurities in sand and gravel to improve the quality of sand. A&…

Vibrating Screen characterizes simple structure, high efficiency, reliable use and convenient installation, and can perform multi-special segmentation screening of loose materials. It is main equipment to separate soild materials, it …

Roller crusher is also known as roll crusher, which relies on the high-speed rotation of roll wheel to crush materials. The commonly used roll crusher types include double roller crusher, toothed roller crusher, four roller crusher, etc. …

Fine crusher is also called tertiary crusher, which adopts the principle of “stone hit stone” to crush materials. It upgrades the traditional three crushing stages to the two crushing stages. A Fine Crusher&n…

Hammer crusher is The high-speed rotating hammer collides with the material to crush the material. It can be crushed in dry and wet forms. A Hammer Crusher, also known as a Hammer Mill Crusher, is a ma…

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy