Search the whole station Crushing Equipment

Fine crusher is also called tertiary crusher, which adopts the principle of “stone hit stone” to crush materials. It upgrades the traditional three crushing stages to the two crushing stages.

A Fine Crusher is a type of machine applying in the final stage of crushing. Its purpose is to take stone that has already been crushed once or twice and reduce it to small, uniform sizes, like sand or fine gravel. We often call it a Sand Making Crusher. But its real secret is not just making things small. It is about creating a perfect particle size distribution. This means you get the right blend of coarse sand, fine sand, and micro-fines. This blend reduces empty spaces in your concrete mix, leading to stronger blocks with a better finish.

Using a high-quality fine crusher brings many benefits to your operation. The most important advantage is product quality. The machine produces aggregates with a cubical shape. This shape is much better for concrete than flaky or elongated particles. Cubical particles lock together better, making your final product stronger.

Another big advantage is the control over “fines,” which are tiny particles smaller than dust. Many people think these fines are a problem. But in block making, they are a feature. A controlled amount of these micro-fines acts like tiny ball bearings in your concrete mix. This helps the concrete flow better into the molds. It also fills the smallest gaps, giving you a denser block with a very smooth surface. This is a key feature of our ZONEDING machines. We design them to help you control the amount of fines you produce.

The fine crusher is suitable for grinding and processing in metallurgy, building materials, chemical, mining, railway, water conservancy and other industries. It applys before the ball mill to increase the production efficiency of the ball mill by 50%.

The Aggregate Crusher is essential in many industries. Its main use is in creating high-quality M sand for concrete and asphalt. It is a key part of any modern Sand Production Line. You will also find it in mining operations to process minerals.

Standard crushers make dangerous, sharp glass shards. We used a special fine crusher, a Vertical Shaft Impactor (VSI), to make the glass particles hit each other. This rounded their edges and created a beautiful, safe glass sand. They used this sand to make high-end architectural pavers that sold for a premium price. This shows how a fine crusher can turn waste into value.

It is especially suitable for fine and medium crushing of materials with hardness below 9 such as quartz, feldspar, calcite, marble, ceramics, iron ore, copper ore, gangue, phosphate rock, granite, basalt, silicon carbide, corundum, insulation materials and other brittle materials.

The type of material you crush directly impacts the machine’s wear parts. For harder, more abrasive materials like granite, you need tougher parts to avoid constant replacements.

The working principle depends on the type of fine crusher. The two most common types are Vertical Shaft Impactors (VSI) and high-speed hammer mills. In a VSI, the stone is fed into the center of a rapidly spinning rotor. The rotor throws the stone outwards at high speed. The stone then smashes against other rocks in the crushing chamber. This is “rock-on-rock” crushing. It is very effective at creating a good cubical shape.

In a hammer mill or Impact Crusher For Sand, the stone is hit by hammers that are spinning on a rotor. The stone shatters upon impact and is thrown against liner plates inside the machine for further size reduction.

Once the crushing process is complete, the crushed materials are expelled or belched out of the machine.

1.High crushing efficiency. The use of grate plate, rigid hard extrusion crushing and solid rotor body greatly improve the crushing efficiency.

2.Good crushing effect. The fine crusher can arbitrarily control the discharging size of materials, so the required material size can reach more than 95% and ideal material size control and classification can be realized.

3.Small wear parts wearing. Compared with hammer crushers and impact crushers, it only wears the hammerhead, while the wheel core and hammer frame have no wear.

4.Simple installation. It is light in weight, diverse in installation (removable installation) and easy to operate.

5.Convenient maintenance. It only needs to lift the upper case and open the lowercase during maintenance. A person can complete a comprehensive inspection and maintenance of the whole machine within 20 minutes with a wrench.

6.Timely discharging. Three discharging channels are adopted to discharge qualified materials in time.

7.Adjustable discharging. The discharging granularity of the fine crusher can be adjusted, and the adjusting plate can be turned over at both ends.

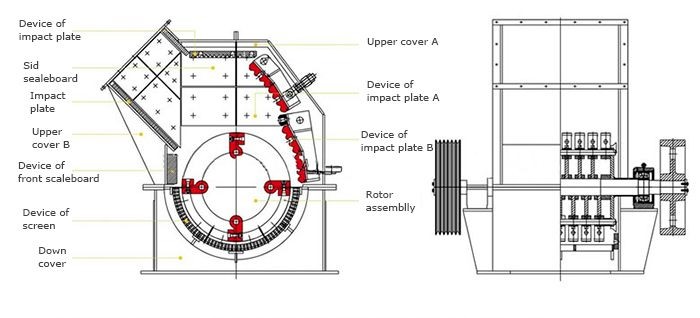

The fine crusher key components are mainly the rotary part, guard plate and box part.

Some non-overlapping hammer carriers are arranged on the wheel core of the rotary part. The hammer head, whose width is larger than the hammer carrier and the wheel hub, is fixed on the hammer carrier. The wheel core is composed of several wheel hubs, which are fixed on the main shaft. The two ends of the main shaft are supported on the frame with rolling bearing seats.

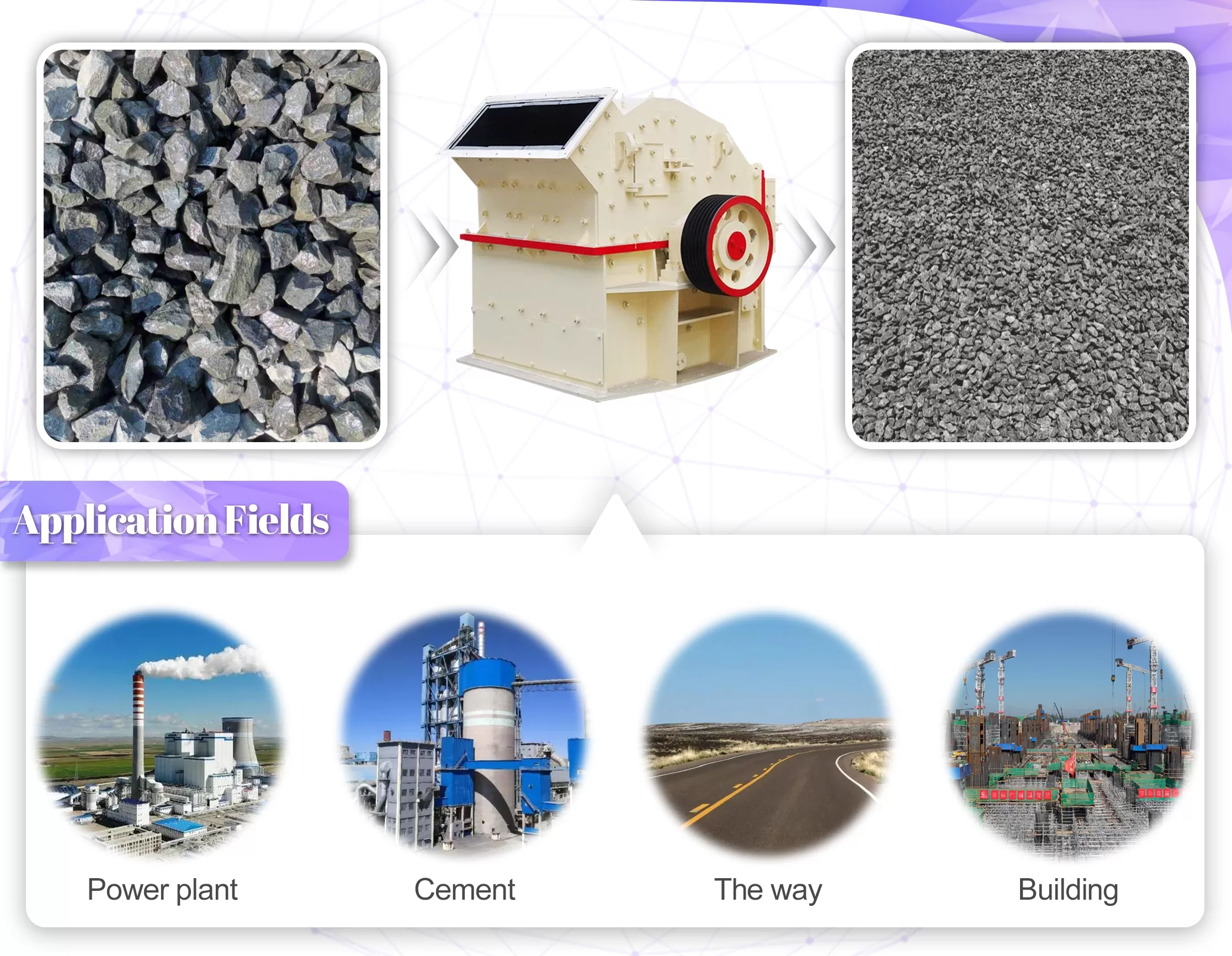

Comparison of Materials before Crushing and After Crushing by Tertiary Crusher

A fine crusher has several key components that work together. Understanding these parts helps with operation and maintenance. The main parts are:

At ZONEDING, we build our fine crushers to solve real-world problems. Our machines are not just powerful; they are smart and durable. We focus on features that increase your uptime and lower your operating costs. For example, the rotors in our crushers are dynamically balanced with extreme precision. This prevents the destructive vibrations that can destroy bearings and crack the machine’s frame.

We also use advanced materials for our wear parts. We offer high-chromium iron and tungsten carbide options. These parts cost more initially but last much longer, saving you money on downtime and replacements. Our crushers also come with options for a Variable Frequency Drive (VFD). This lets you adjust the rotor speed easily, giving you total control over your final product size and shape.

| PXJ tertiary impact crusher | Rotorø×Width (mm) | |||||||

| Specification | 800×400 | 800×600 | 800×800 | 1010×1010 | 1200×1200 | 1400×1400 | 1600×1600 | 1800×1800 |

| Feed opening size(mm) | 400×185 | 500×250 | 550×300 | 1000×350 | 1200×450 | 1500 | 1600×550 | 1800×800 |

| Feeding size (mm) | <120 | <180 | <180 | <180 | <180 | <190 | <190 | <190 |

| Discharging size (mm) | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 |

| Adjustable range of discharge opening (mm) | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 |

| Cement Clinker(t/h) | 10-30 | 1040 | 20-45 | 25-55 | 35-90 | 50-150 | 85-210 | 125-270 |

| Limestone(t/h) | 18-45 | 23-55 | 28-65 | 35-75 | 45-110 | 50-150 | 95-260 | 140-310 |

| Power(kw) | 4P 37KW | 4P 45KW | 4P 45KW | 4P 55KW | 6P 110KW | 6P 160KW | 4P 250KW | 4P 315KW |

| Theoretical weight | 3.9 | 4.5 | 6 | 10.5 | 14.4 | 22 | 35 | 49.7 |

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Jaw Crushers Applicable Material:Quartz, granite, basalt, limestone, river stone, marble, shale, iron ore, copper ore, gold ore etc. A Jaw crusher is mainly used for medium-sized crushing of various ores and…

Cone crusher is usually used as secondary or tertiary crushing stage. It is characterized by robust structure, excellent productivity and simple operation. Cone crusher is ideal for crushing different stone and ro…

Sand making machine is suitable for soft or medium hard and very hard ore materials with hardness not higher than 320 Pa. Also. It has the characteristics of stable and reliable work, easy maintenance, and a high sand production rate. The…

Impact crusher excel in primary crushing of rock. Stationary and mobile plants are available. Replacement of wearing parts is simple due to the hydraulic folding of the housing components. A variety of models are available | Get the fre…

The vibrating feeder (vibratory feeder) is suitable for bulk and granular materials such as limestone, calcite, dolomite, barite, talc, gypsum. And also quartz stone, river pebble, granite, basalt, construction waste, iron ore, coal, slag, …

Sand washing machine is an important equipment for artificial sand and natural sand washing operation. It can wash away the trace stone powder and impurities in sand and gravel to improve the quality of sand. A&…

Vibrating Screen characterizes simple structure, high efficiency, reliable use and convenient installation, and can perform multi-special segmentation screening of loose materials. It is main equipment to separate soild materials, it …

Roller crusher is also known as roll crusher, which relies on the high-speed rotation of roll wheel to crush materials. The commonly used roll crusher types include double roller crusher, toothed roller crusher, four roller crusher, etc. …

Compound crusher is the newly developed equipment by combining sand making machine and the crushing principle of impact crusher. A compound crusher, also called vertical compound sand maker, is a double-rotor prim…

Hammer crusher is The high-speed rotating hammer collides with the material to crush the material. It can be crushed in dry and wet forms. A Hammer Crusher, also known as a Hammer Mill Crusher, is a ma…

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy