Search the whole station Crushing Equipment

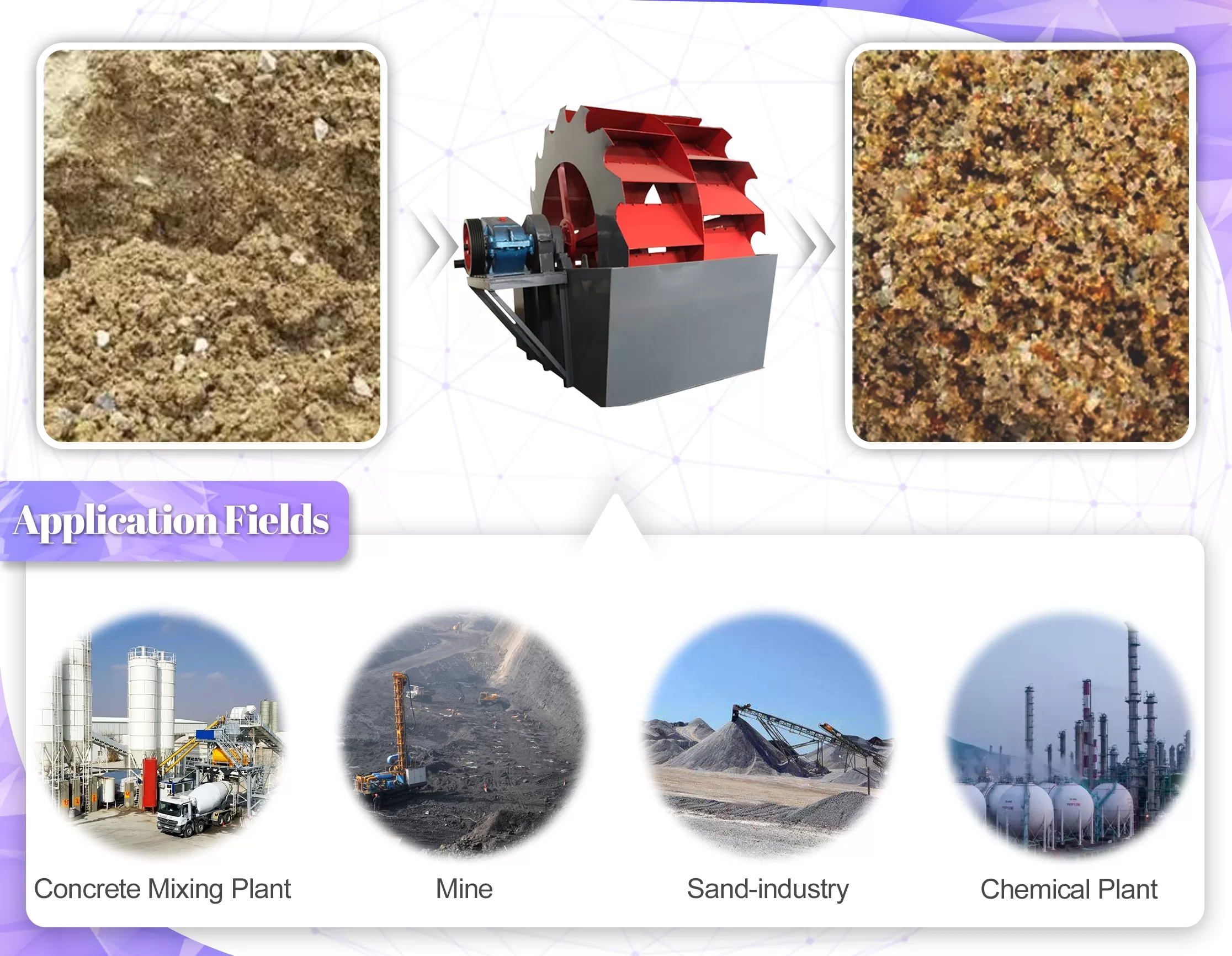

Sand washing machine is an important equipment for artificial sand and natural sand washing operation. It can wash away the trace stone powder and impurities in sand and gravel to improve the quality of sand.

A Sand Washing Machine, often called a sand washer, is a piece of aggregate washing equipment used in quarries, mines, and recycling operations. Think of it as a specialized, heavy-duty dishwasher for sand. Its main job is to scrub and rinse sand with water to get rid of harmful materials. The clean, graded sand that comes out is perfect for high-specification applications, ensuring the strength and durability of construction projects. This sand cleaning machine is a critical step for producing certified construction sand.

The primary application is in the construction industry for producing concrete and asphalt sand. It’s also vital in glass manufacturing, where silica sand must be extremely pure. Other key applications include:

In a complete sand wash plant, the sand washer plays the crucial role of quality control. The process typically starts with crushing large rocks, followed by screening to separate materials by size. The sand that comes from the screening plant is often still mixed with fine dust, clay, and silt. The sand washing machine is placed after the screening stage. It takes this raw feed and performs the final cleaning step, ensuring the product is ready for dewatering and stockpiling. Without this stage, the entire production line would yield a low-quality, less valuable product.

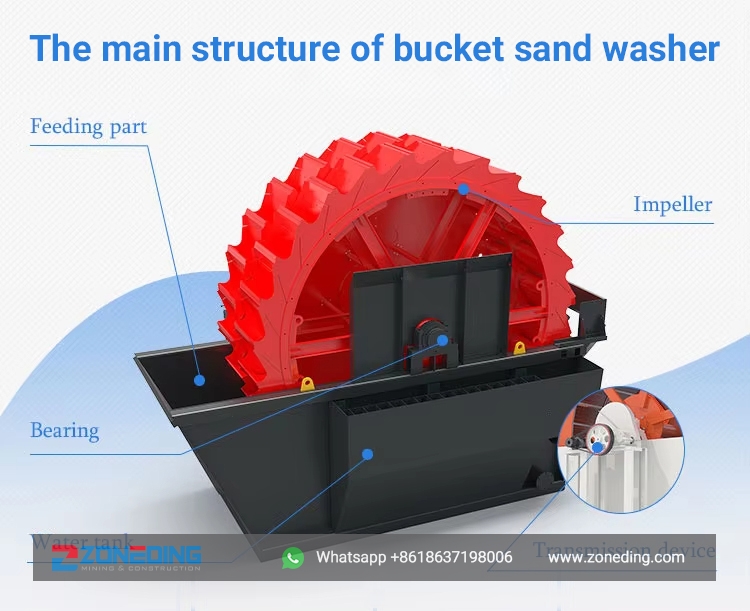

The sand washer adopts a wheel structure and consists of a feeding part, a transmission device, an impeller, a bearing, and a water tank.

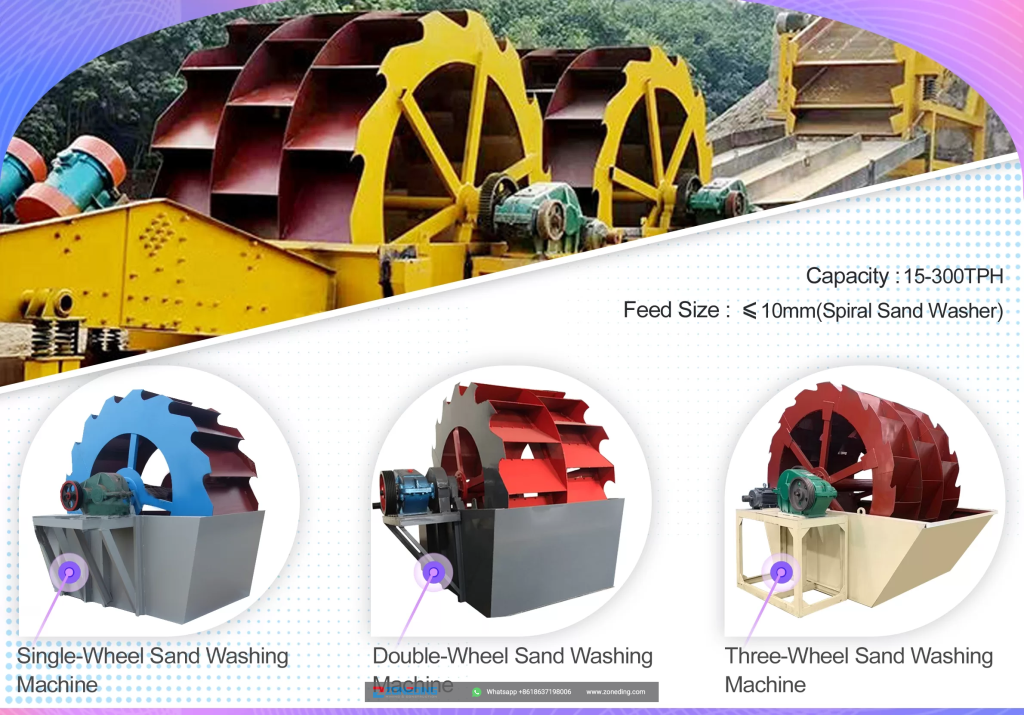

Its power depends on models and how many impellers you use. Its types include single-wheel, double-wheel, and three-wheel, and there is no mobile type. The larger the impeller diameter, the higher the efficiency.

The structure of a sand washing machine is simple and robust, designed for tough working conditions. The main components include:

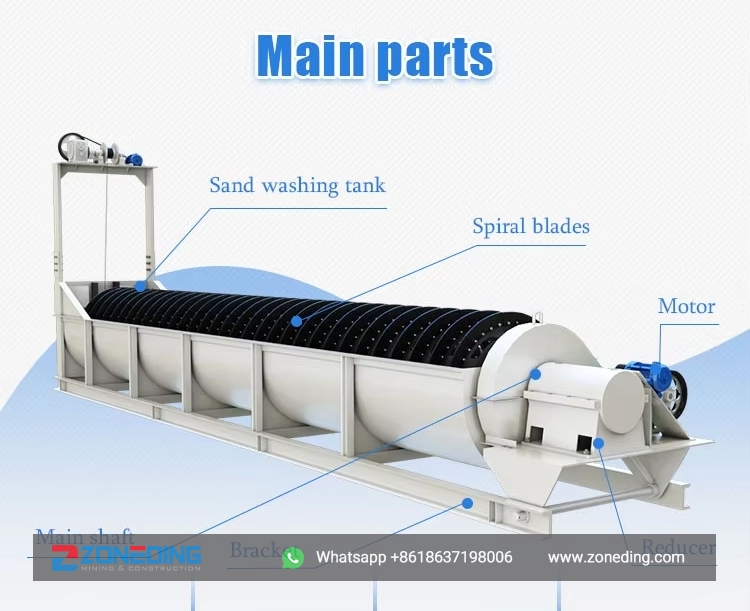

The rotor adopts a central structure. The spiral blade is installed on the main shaft and connected to the reducer to work. The impeller drives the bearing device to isolate the bearing from water and materials, ensuring that the finished product is not contaminated and effectively improving the cleaning effect.

You need a sand washing machine to turn a basic raw material into a valuable, specified product. Unwashed sand, full of clay and silt, creates weak spots in concrete, requires more cement to achieve strength, and can cause projects to fail inspection. By investing in a sand washer, you can guarantee your product meets industry specifications like ASTM C33. This not only allows you to sell your sand at a much higher price but also builds your reputation as a provider of quality materials, opening doors to larger and more profitable projects.

1.The motor drives the impeller to rotate slowly through the V-belt, reducer, and gear reduction.

2.Sand and gravel enter the washing tank through the feed chute and roll under the impeller’s action, grinding against each other to remove impurities covering their 3.surfaces. This process also breaks the water vapor layer coating the sand grains, facilitating dehydration.

4.Water is added to create a strong current that carries away impurities and lightweight foreign objects in a timely manner, discharging them through the overflow outlet of the washing tank.

5.The clean sand and gravel are then taken away by the blades and finally poured into the discharge chute from the rotating impeller, completing the sand and gravel washing process.

Sand Washing Machines

A bucket-type sand washer is also widely used in sand washing plants, and it is mainly used to washing away soil and dust. Its main parts are the feeding part, driving device, impeller, water tank. The raw sand firstly enters the washing tank through the feeding port, then being rolled and ground by the rotating impellers to be purified.

The power of the sand washing machine depends on models and how many impellers you use. The larger the impeller diameter, the higher the efficiency.

The sand washing process uses water and agitation to separate particles by weight. First, the raw sand feed is mixed with water and fed into the washer’s tank, creating a slurry. The rotating wheel or spiral vigorously churns this mixture. The heavy, desirable sand particles sink to the bottom of the tank. The lighter, unwanted particles like clay, silt, and dust get suspended in the water. This dirty water then flows over a weir and out of the machine, taking the contaminants with it. Meanwhile, the clean sand is scooped up by the buckets or pushed up the incline by the screw and discharged, ready for the next stage.

Using a sand washer offers significant benefits that directly impact your bottom line. The most obvious benefit is the improved quality of your sand, leading to higher strength in concrete and asphalt. This allows you to command a higher price for your product. Beyond that, a sand wash process can help you create valuable byproducts. Don’t just discard the “waste” slurry. This slurry often contains fine aggregates or minerals. With a recovery system, you can separate these materials, creating an additional revenue stream and reducing waste disposal costs, making your entire quarry wash plant more sustainable and profitable.

There are two main types of sand washers, and the right choice depends on your specific material and goals.

Main Features of Sand Washing Machine :

1. Little loss for medium-sized or fine sand and stone powder.

2. Almost no easily-damaged parts.

3. Long working life.

4. Easy maintenance.

Main Features of Spiral Sand Washing Machine :

1. High level cleaning and reasonable structure.

2. Large capacity and small power consumption.

3. Small loss of sand during the process of sand washing.

| Specification | Processing Capacity(t/h) | Motor Power(kw) |

| 2208 | 15-40 | 8p 4kw |

| 2611 | 20-65 | 8p 5.5kw |

| 2914 | 50-100 | 8p 7.5kw |

| 3020 | 80-200 | 8p 11kw |

| 3121 | 90-260 | 8p 11KW |

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Jaw Crushers Applicable Material:Quartz, granite, basalt, limestone, river stone, marble, shale, iron ore, copper ore, gold ore etc. A Jaw crusher is mainly used for medium-sized crushing of various ores and…

Cone crusher is usually used as secondary or tertiary crushing stage. It is characterized by robust structure, excellent productivity and simple operation. Cone crusher is ideal for crushing different stone and ro…

Sand making machine is suitable for soft or medium hard and very hard ore materials with hardness not higher than 320 Pa. Also. It has the characteristics of stable and reliable work, easy maintenance, and a high sand production rate. The…

Impact crusher excel in primary crushing of rock. Stationary and mobile plants are available. Replacement of wearing parts is simple due to the hydraulic folding of the housing components. A variety of models are available | Get the fre…

The vibrating feeder (vibratory feeder) is suitable for bulk and granular materials such as limestone, calcite, dolomite, barite, talc, gypsum. And also quartz stone, river pebble, granite, basalt, construction waste, iron ore, coal, slag, …

Vibrating Screen characterizes simple structure, high efficiency, reliable use and convenient installation, and can perform multi-special segmentation screening of loose materials. It is main equipment to separate soild materials, it …

Roller crusher is also known as roll crusher, which relies on the high-speed rotation of roll wheel to crush materials. The commonly used roll crusher types include double roller crusher, toothed roller crusher, four roller crusher, etc. …

Fine crusher is also called tertiary crusher, which adopts the principle of “stone hit stone” to crush materials. It upgrades the traditional three crushing stages to the two crushing stages. A Fine Crusher&n…

Compound crusher is the newly developed equipment by combining sand making machine and the crushing principle of impact crusher. A compound crusher, also called vertical compound sand maker, is a double-rotor prim…

Hammer crusher is The high-speed rotating hammer collides with the material to crush the material. It can be crushed in dry and wet forms. A Hammer Crusher, also known as a Hammer Mill Crusher, is a ma…

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy