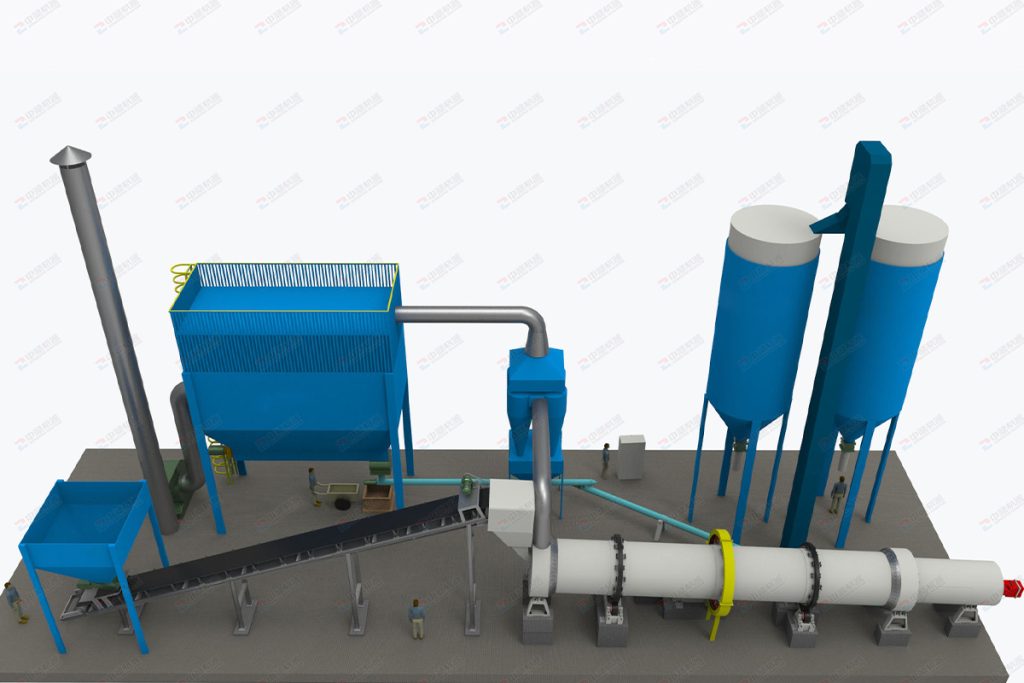

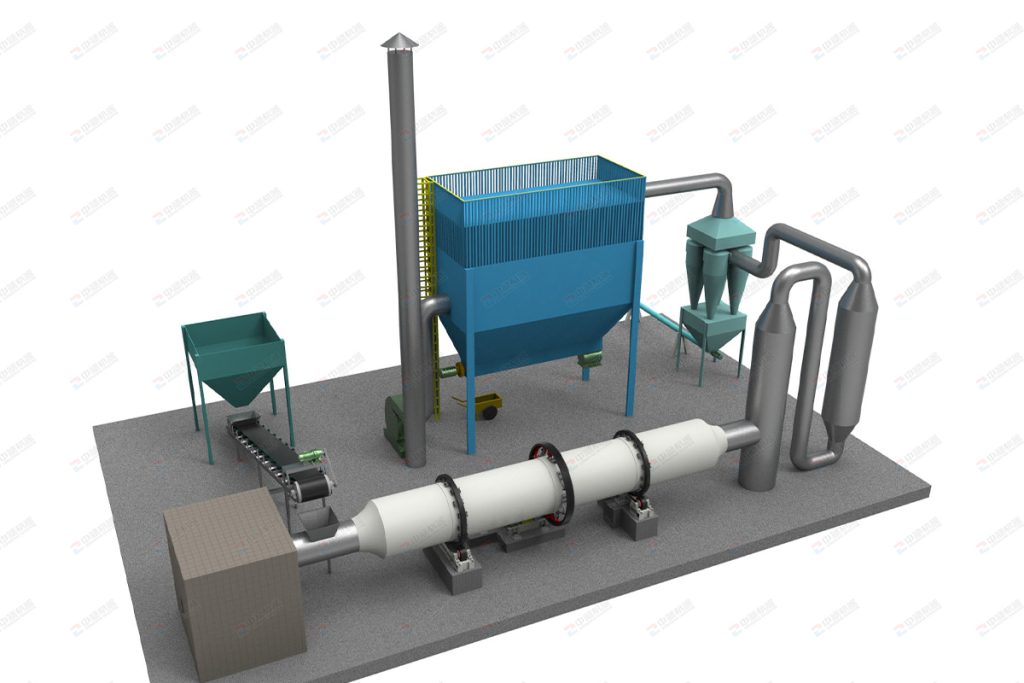

complete SYSTEMS

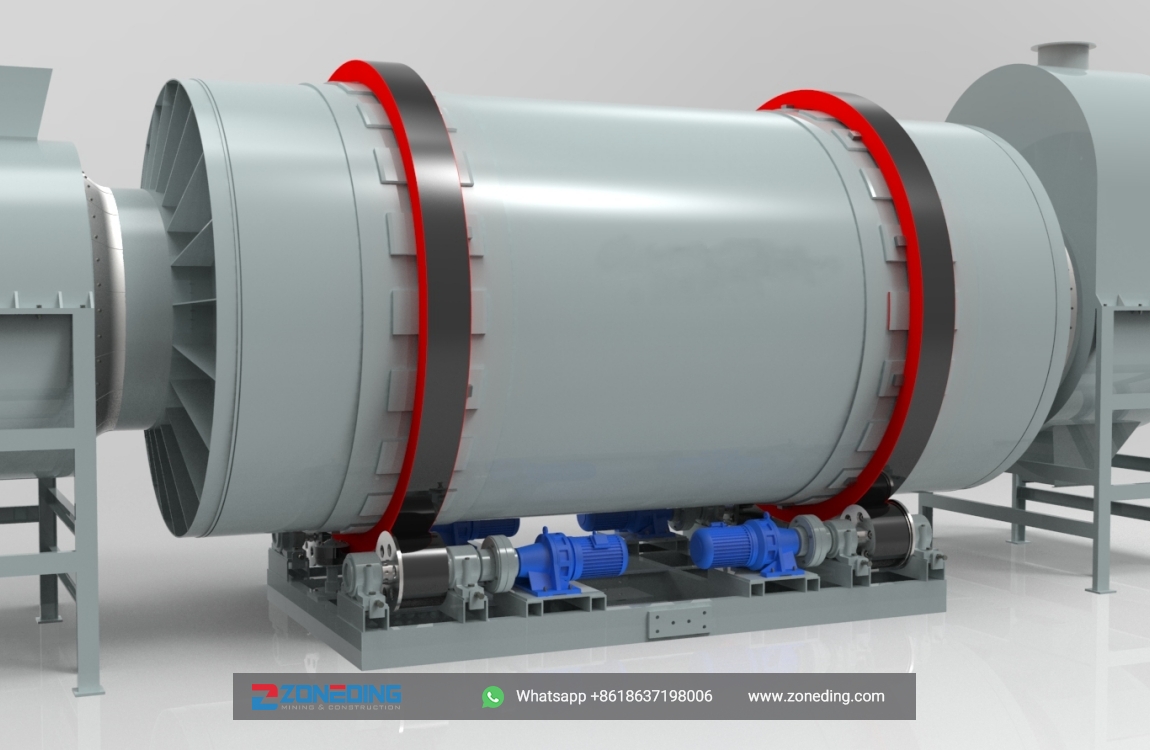

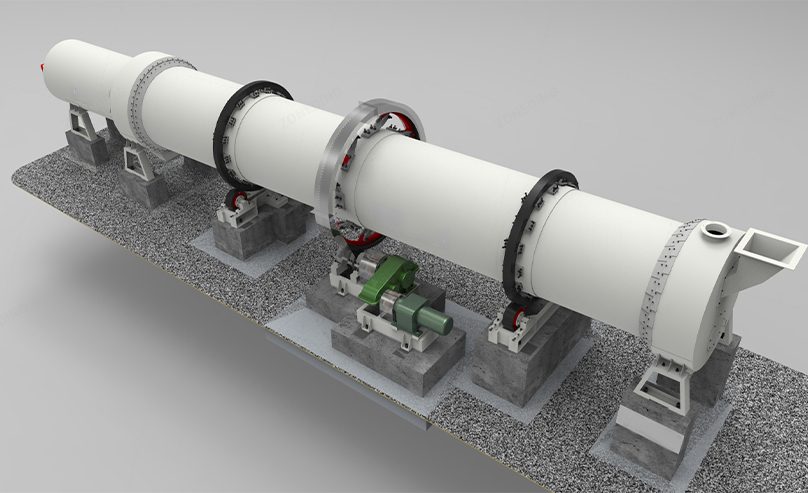

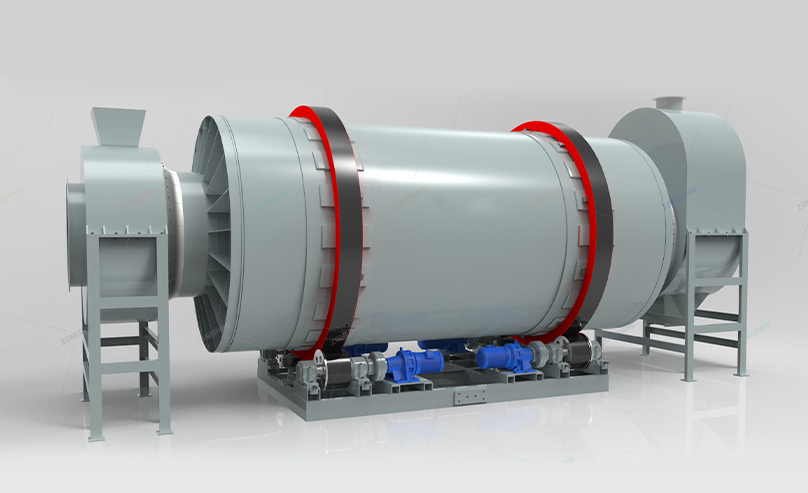

Rotary Thermal Dryers and Drying Systems

ZONEDING is a leading manufacturer specializing in industrial drying equipment and mineral processing solutions, integrating R&D, design, production, installation, and service to deliver energy-efficient customized systems for global clients. As a premium supplier of mining equipment, our product portfolio includes dryers (e.g., slag, sludge, and lignite dryers), crushers, screening equipment, conveying systems, and full turnkey production line solutions (EPC) from single machines to complete plant engineering.

Industries We Serve

Our systems are used for sand/rock/aggregate, as well as silted fly ash, sewage sludge, organic fertilizer, coal, bulk materials and biomass. We design and build our systems, integrate related plant systems and have full EPC capabilities.

Gypsum Dryer

Buy industrial gypsum dryer for sale. Efficiently remove moisture from gypsum rock & powder. Improve product quality & processing speed.

Rotary Cooler

Rotary cooler for sale. Efficiently cool hot materials discharged from kilns & dryers. Improve process speed & material quality.

Rotary Kiln

Buy industrial rotary kiln for sale. Achieve efficient high-temperature thermal processing, calcining, roasting & drying of minerals, ore, cement & more.

Sludge Dryer

Find high-efficiency sludge dryers for sale. Reduce sludge volume, cut disposal costs, and improve handling. Ideal for municipal & industrial applications.

Aggregate and sand dryers

Discover high-performance aggregate and sand dryers for sale. We offer triple-pass and rotary drum models for efficient moisture removal. Get a quote today!

Three drum Dryer

Looking for a high-efficiency triple-drum rotary dryer? Saves energy, space, and cost; suitable for drying sand, coal, and biomass. Rugged and reliable.

Bentonite Dryer

Purchase an industrial bentonite dryer suitable for various applications such as drilling mud, cat litter, and foundry work. Achieve optimal moisture content and uniform drying.

Coal Dryer

Specialized Coal Dryer machines for power generation, coking, and briquetting. Improve fuel efficiency, reduce transport costs & enhance combustion.

Slurry Dryer

Professional slurry dryer manufacturer with CE/ISO certification. Customizable 5-50t/h capacity, 35% energy saving. Get instant technical specs download.

Slag Dryer

Professional slag dryer manufacturer with CE/ISO certification. Energy-saving 30%, global delivery to 50+ countries. Get custom solutions for mining waste processing.

Ore Powder Dryer

This mineral powder dryer is specifically designed for use with mineral concentrates, iron ore powder, and metallurgical slag. It ensures uniform drying, improving product quality and recovery rates.

Sawdust Dryer

Searching for a reliable sawdust dryer? Our industrial machines provide fast moisture reduction for biomass pellets. Factory-direct pricing. Get a quote today!

Rotary Dryer

Zoneding Machine manufactures robust and durable rotary dryers for efficient industrial drying of bulk materials (minerals, biomass, sand, etc.).

Lignite Dryer

Purchase industrial lignite dryers. Improve the calorific value of lignite, reduce moisture content, and optimize its applications in power generation and briquetting. Customized solutions are available.

loading...

已经是到最后一篇内容了!

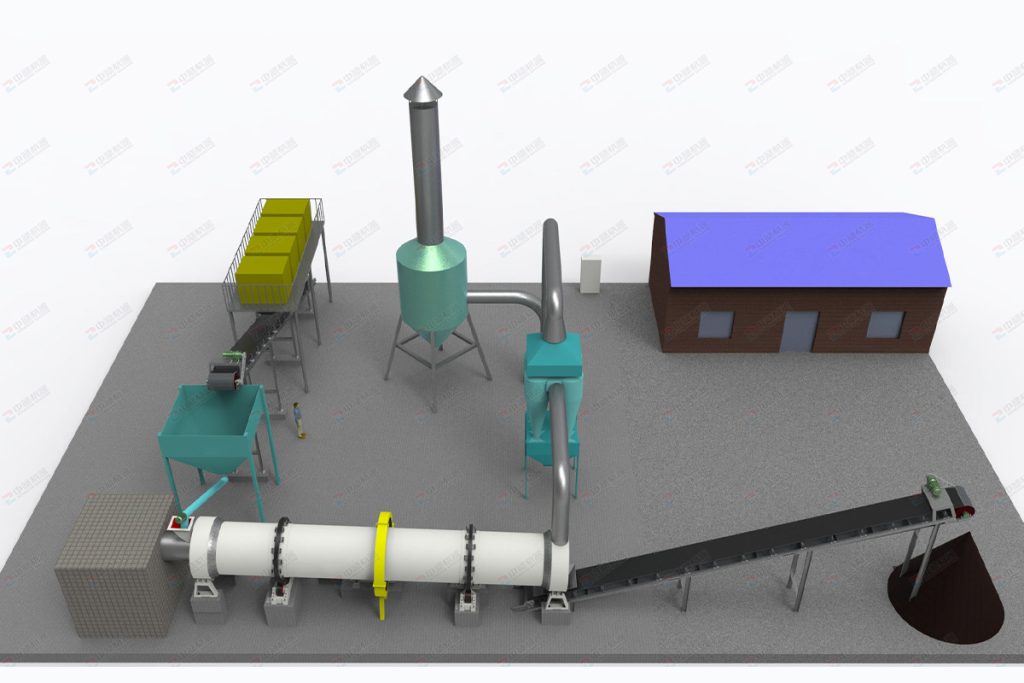

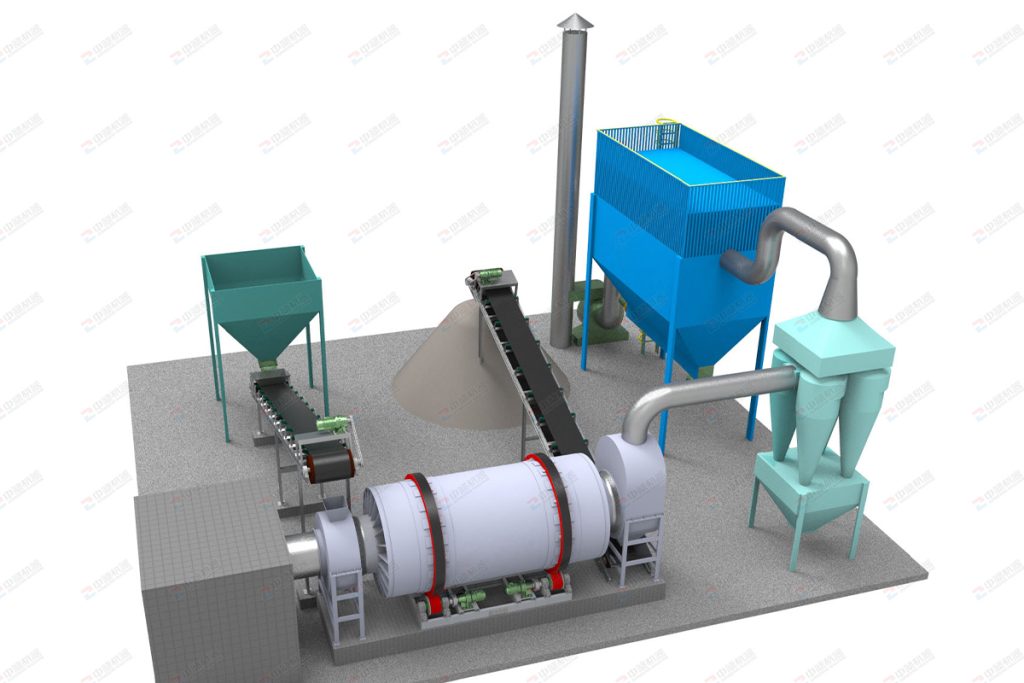

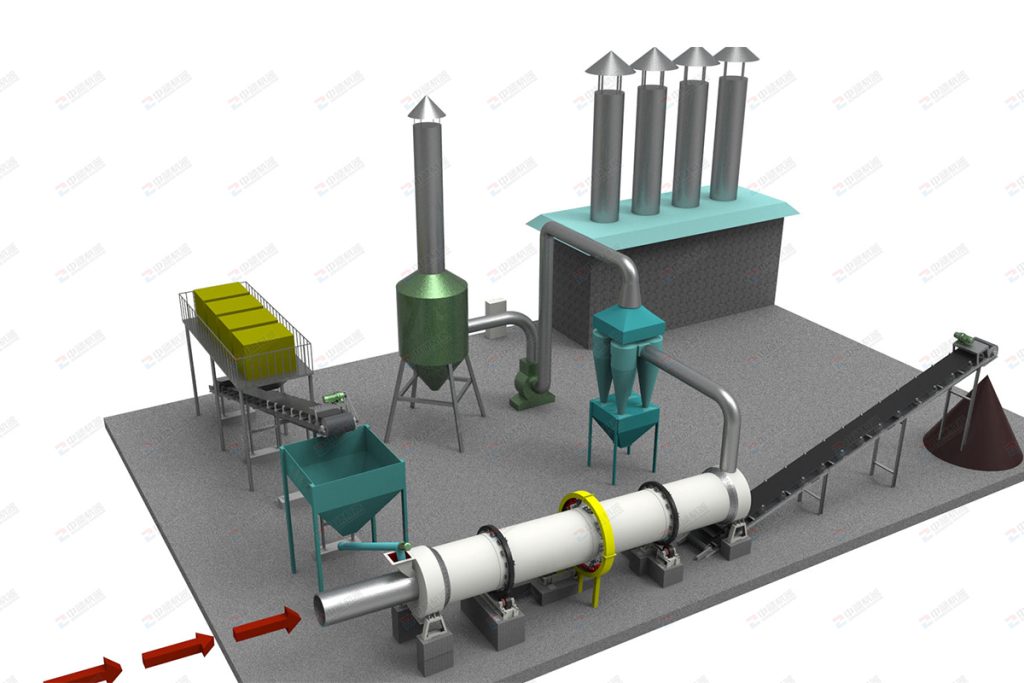

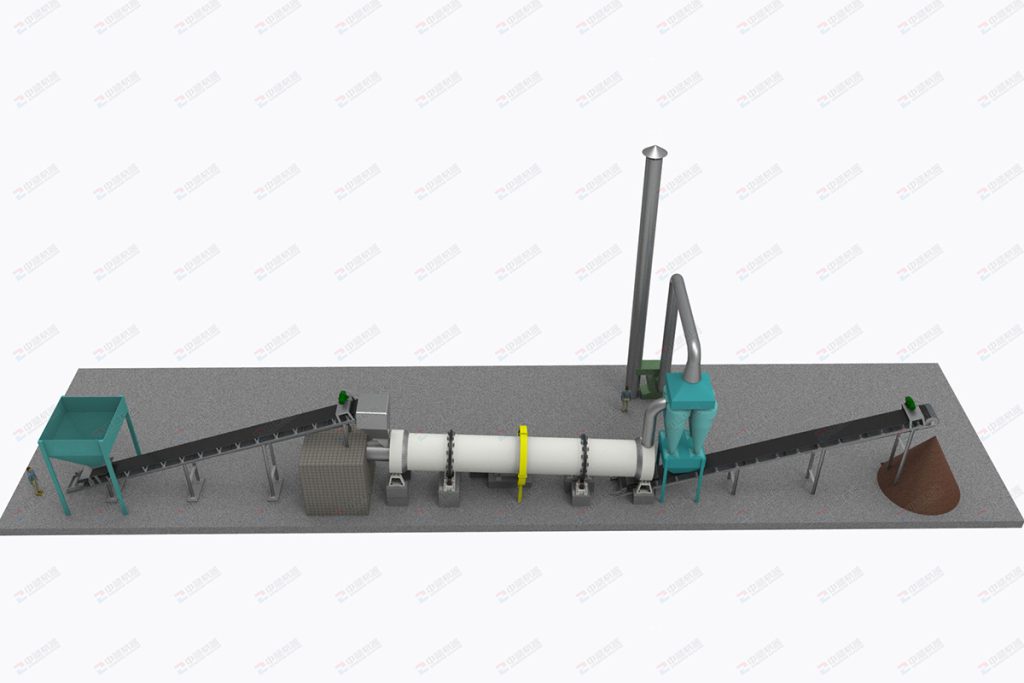

ZONEDING Complete Drying Systems

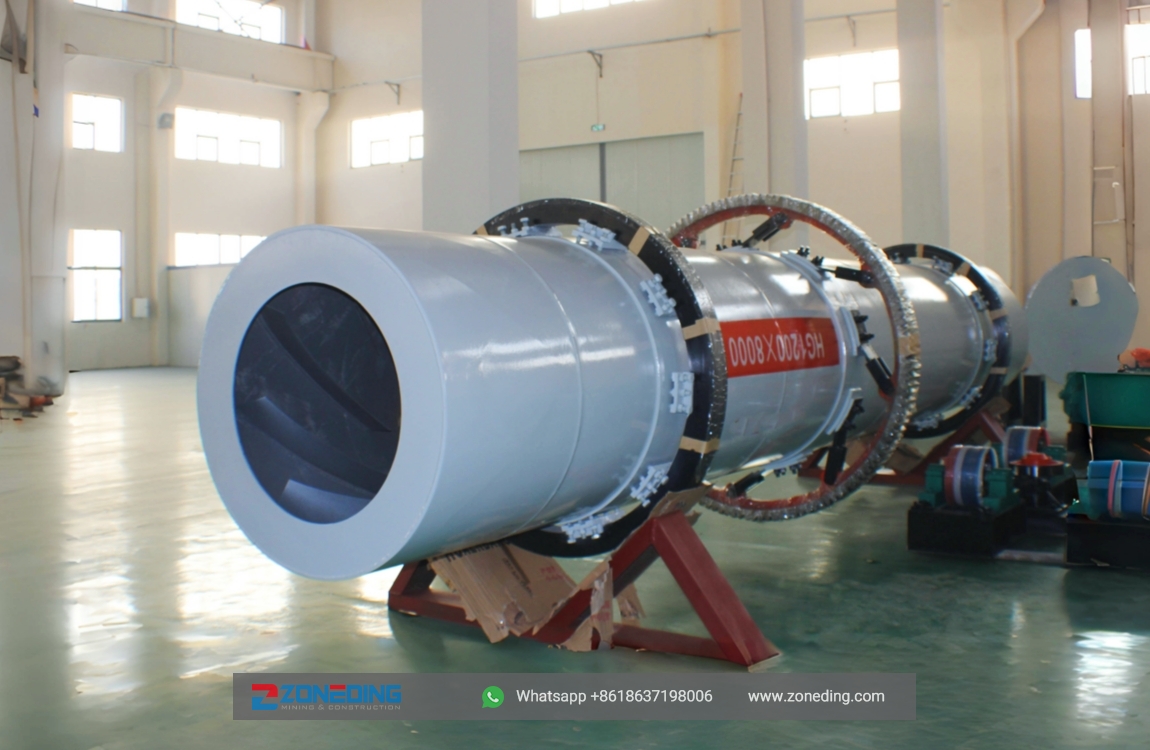

The drying capacity of our rotary dryer systems is from 5 tons per hour to 300 tons per hour. ZONEDING has installed over 80 complete plants around the world following stringent electrical, air pollution control, and safety codes.

Featured Projects

Company Production Ability

ZONEDING is eager to design, manufacture, transport, install and finally commission the entire facility.

Zoneding Machine

Zoneding Machine