Industrial and Agro Waste Briquette Machine and Solution

As one of China's leading experts in the manufacturing and supplying for the machinery and equipment of briquetting, compaction, drying and crushing processes. ZONEDING provides equipment and technology for the regeneration of valuable secondary raw materials from industry to biowaste.

Our technical team of process engineers and after-sales service support technicians have helped customers find the potential of their waste through briquette solution development. Our main goal is to maximize customer satisfaction by providing the greatest possible benefits from our products and services.

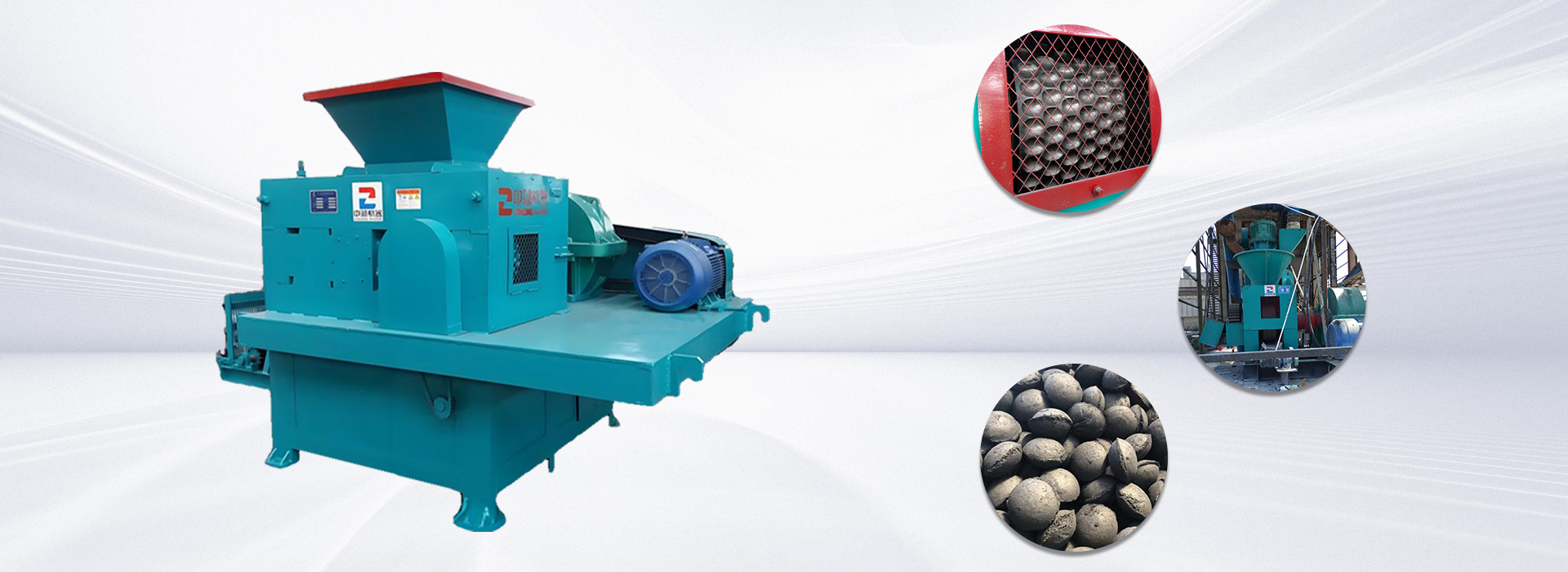

Briquette Machine

Dry Powder Briquetting Machine

Applied Materials:nMagnesium powder, iron powder, manganese powder, bauxite, graphite powder, clay, limestone, ilmenite concentrate powder, titanium powder, manganese powder, silicon manganese alloy, etc. Dry powd...

Pulverized Coal Briquetting Machine

Applied Materials:Coal ash, pulverized coal, coke powder, iron power, scrap iron, sinter, carbon dust, powdered carbon, slag, gypsum, tailing, slurry, kaolin, active carbon, coke breeze etc. Pulverized coal briq...

Gypsum Briquetting Machine

Raw Materials:nGypsum, tailings, sludge, kaolin, clay, activated carbon, coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, etc. Gypsum briquette machine is mainly ...

Mineral Powder Briquetting Machine

Materials:nMineral powder, metal powder, coal powder, coke powder, iron, ore, iron oxide, slag, refractory and other materials.n A mineral powder briquetting machine is a type of roller press designed for...

Slurry Briquetting Machine

Applied Materials:nIron oxide, sludge iron power, coking coal, refractory material, etc. in the coal industry, power plants, metallurgy industry, chemical industry, energy, transportation, heating, and other industries. ...

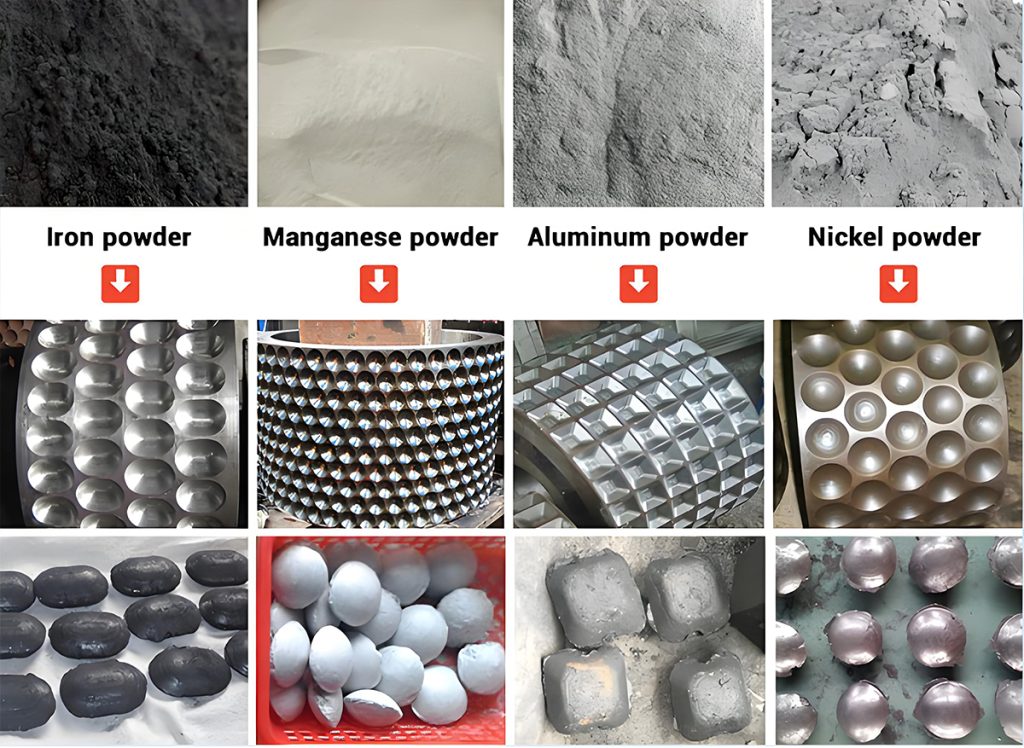

Metal Powder Briquetting Machine

Applied Materials:nAll kinds of metal powder, such as iron powder, copper powder, aluminum powder, tungsten powder, nickel powder, lead powder, and other materials, such as gypsum, coal powder, ore powder, oxide skin, steel slag, and alumin...

Lime Briquetting Machine

Applied Materials:nLime powder briquetting machine is mainly used in coal, mining, metallurgy, refractory material, chemical industry, building materials, etc. Due to the processed materials, lime briquette mach...

Aluminite Powder Briquetting Machine

Applied Materials:nAluminum powder, aluminum ash, copper powder, scrap iron, iron oxide skin, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze. The aluminite powder briquettin...

Iron Powder Briquetting Machine

Iron Powder Briquetting Machine Applied Materials:nFine iron powder, iron oxide scale, steel slag/sludge, mill scale, manganese ore fines, charcoal powder, coal fines, coke fines, carbon black, etc. Whatsapp+8618637198006 Email:z...

Briquetting Plant

Applied Materials:nvarious fines and powder of coal, coke, charcoal, carbon black, iron ore, mineral powder, metal dust, cast iron dust, mill scale, manganese ore, fluorite, gypsum, ferrosilicon, nickel alloy, blast furnace ash, etc. ...

loading...

已经是到最后一篇内容了!

Application Materials

ZONEDING briquette machines can process 4 types of materials:

- Charcoal powder:

coconut shells, rick husks, bamboo shavings, corn stalks, cotton straws, and other agricultural wastes. Note that we don't process Shisha Charcoal (hookah coals). - Coal:

coal slurry, coal dust, coal fines, coal powder, fly ash etc. - Metal ore powder:

iron powder, sponge iron powder, manganese ore fines, aluminum powder, silicon powder, ore tailings, etc. - Non-metallic ore powder:

asphalt powder, gypsum powder, sludge, kaolin, quicklime/ hydrated lime, fiber powder, fluorspar powder, pet coke fines, etc.

Briquette making machine accessories

We can press into various shapes

The final shaped balls can be made into spherical, square, pillow, and oval shapes. In addition, special shapes can be customized according to your needs.

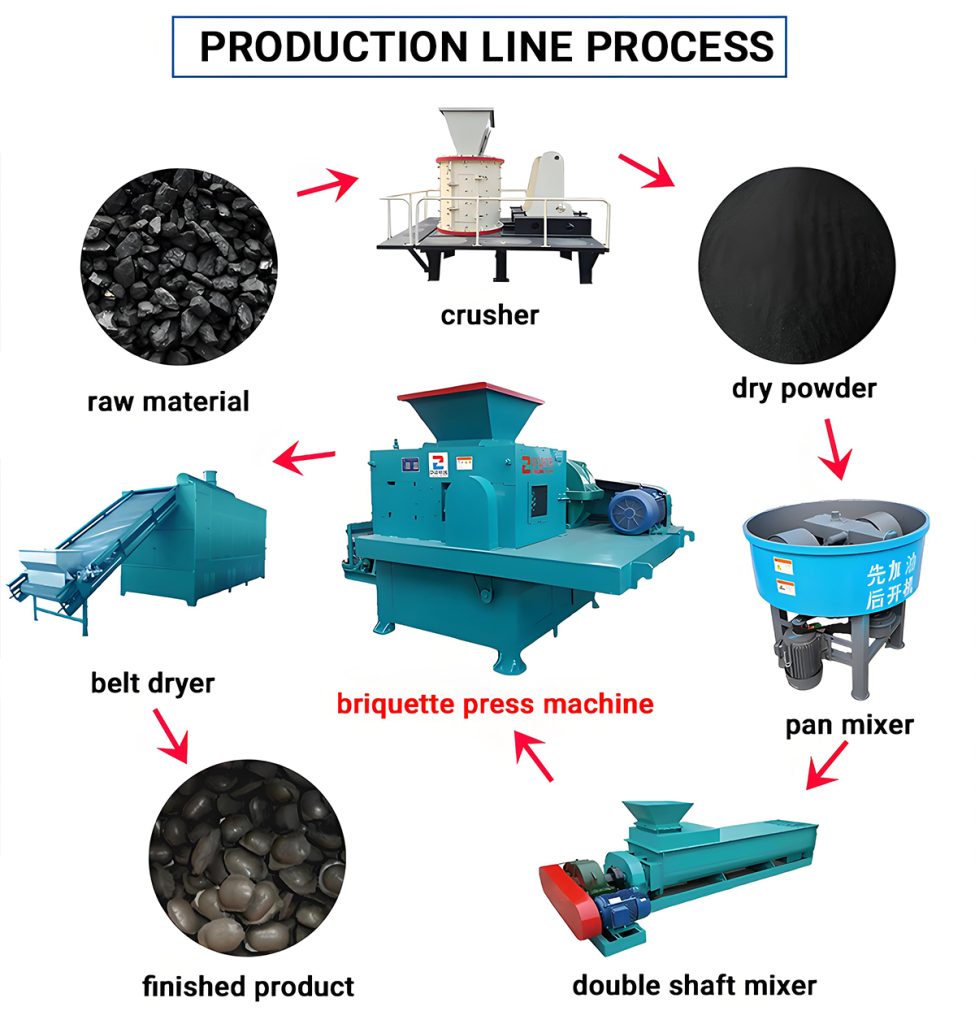

Briquette Machine Process

The briquette press machine is the core equipment of the briquetting making plant, and the supporting equipment includes hammer crusher, binder mixer, vertical dryer, biaxial mixer, feeder, mesh belt dryer, etc. According to the needs of customers, we will configure different solutions.

Project Case

FAQ’s

A. Run a briquette plant is an easy way if you have proper material, make sure it has proper size, proper moisture, etc. Add proper material into the briquette machine and then the briquette is made! So, what our work is to make the material with that PROPER. And if purchasing from us, our engineer also can be out abroad to help you guiding set up your briquette plant.

A. ZONEDING can arrange the visit if you want, but please contact us in advance for the arrangement as some of the plant is very far away.

A. Absolutely. FREE TEST is acceptable now. Deliver your material with suitable weight we will back to you a test report with test video. Sample briquettes also can be taken for your further analysis.

A. The machine making process will begin as long as the payment is made, the produce time will be around 10-20 days, and other time for arranging the shipping will be about 7 days. The shipping time will be much different in different places from 10 days to even 30 days.

A. It depends on the material and the working condition as well. Most of the material need to add binder when on briquetting, binder is also a good additive for protecting your briquetting system, but not all the materials need this, especially you are briquetting material like BIOMASS, LIME, etc. You can also briquette without binder by using hydraulic briquette press with high pressure, contact us and we will help to find your own briquette way.

A. Of course, almost all the materials can be briquette, the biggest problem for consideration should be running cost (electric, binder, workers, etc) and the investment (the briquette way, the plant equipment, etc).

Zoneding Machine

Zoneding Machine